Evaporative crystallization system for continuously producing low-density crystal substances from mixed solution and process thereof

An evaporative crystallization, low-density technology, applied in solution crystallization, general layout of crystallization device, separation/purification of carboxylic acid compounds, etc., can solve problems such as poor product quality stability, difficult product specification control, product coalescence, etc. Achieve the effect of reducing labor intensity, facilitating production management, and stabilizing the crystallization process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] This embodiment is used to illustrate the calcium propionate crystal provided by the present invention and its production method.

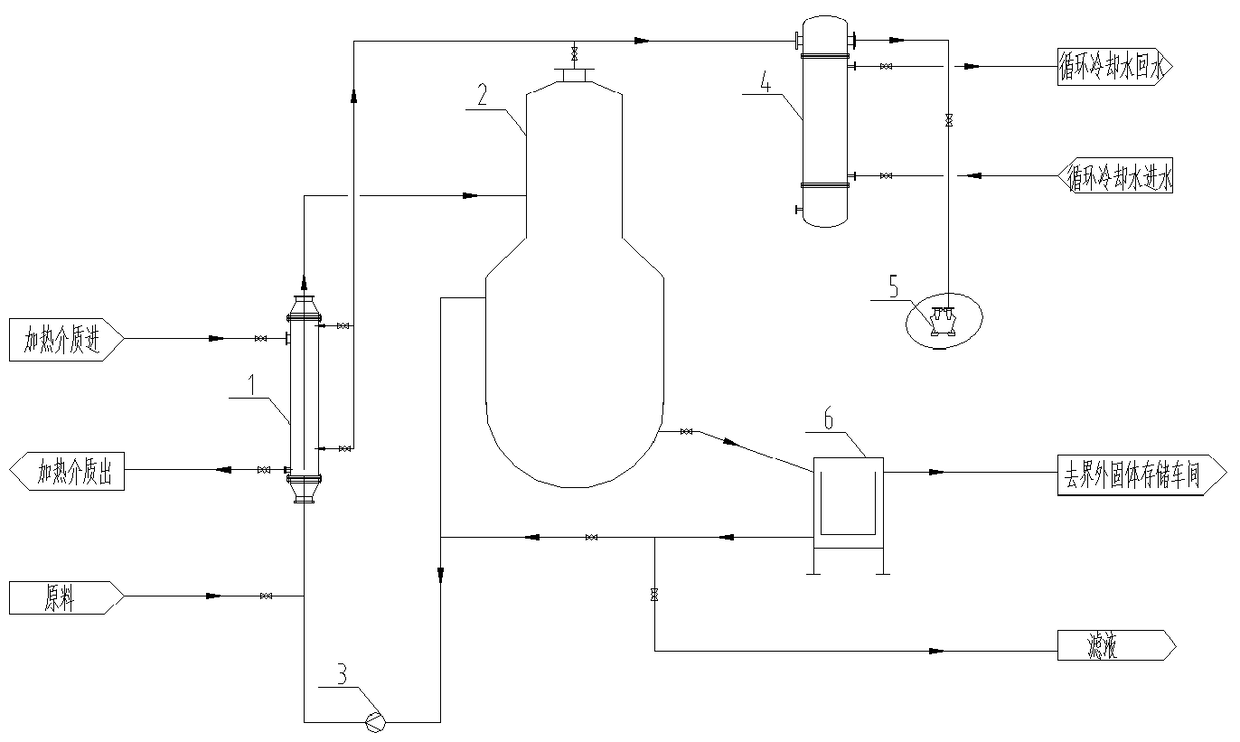

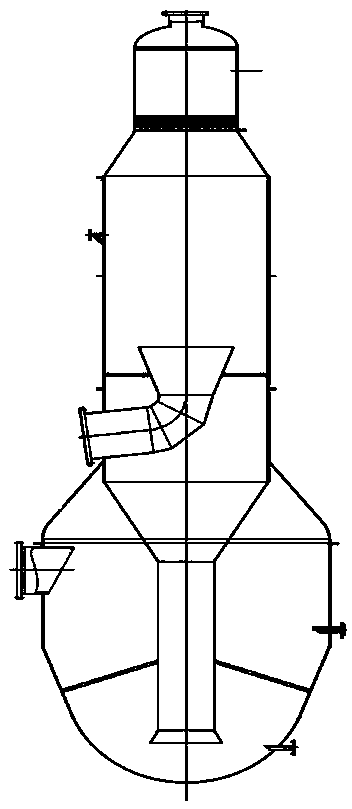

[0052]The calcium propionate raw material liquid is transported to the circulation pipeline of the evaporative crystallization system through the feed pipeline, and after being flashed and concentrated in the separation chamber of the heat exchange device 1 and the crystallization device 2-Oslo evaporative crystallizer, it enters the Oslo evaporation through the central downcomer The crystallization chamber of the crystallizer carries out crystal growth, and the liquid level in the crystallizer is controlled to be 30 cm lower than the feed port of the separation chamber, and the circulation amount of the crystallization process is controlled by the circulation device 3 to be 200 times of the feed amount, and the vacuum device 5 pipeline valve is adjusted The vacuum degree in the crystallizer is controlled by the opening degree to 20kPa, and ...

Embodiment 2

[0054] This embodiment is used to illustrate the calcium propionate crystal provided by the present invention and its production method.

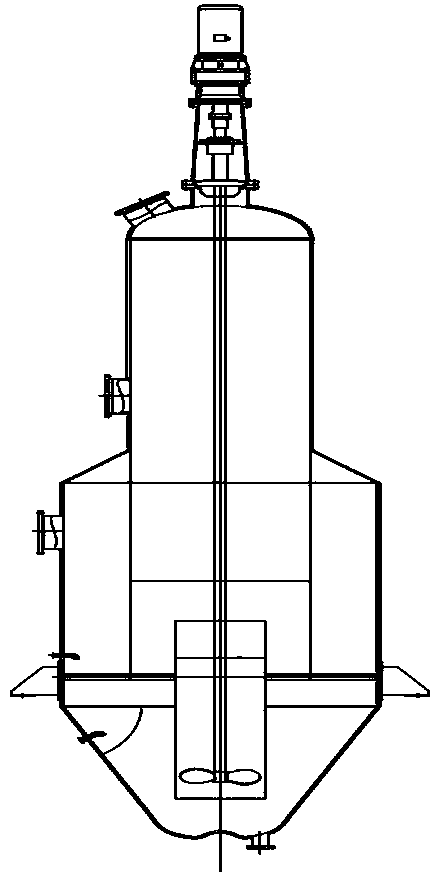

[0055] The calcium propionate raw material liquid is transported to the circulation pipeline of the evaporative crystallization device through the feed pipeline, and after being flashed and concentrated in the separation chamber of the heat exchange device 1 and the crystallization device 2-DTB type evaporative crystallizer, it enters the DTB type evaporative crystallizer through the draft tube. The crystallization chamber of the evaporative crystallizer carries out crystal growth, and the liquid level in the crystallizer is controlled to be 10cm lower than the feed port of the separation chamber, and the circulation amount of the crystallization process is controlled to be 80 times of the feed amount through the circulation device 3, and the DTB type evaporative crystallizer is controlled The stirring rate is controlled by adjusting the val...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com