A non-metal ion-doped perovskite-type mixed conductor hydrogen permeable film and its preparation method and application

A perovskite-type, mixed-conductor technology, which is applied in separation methods, non-metallic elements, chemical instruments and methods, etc., can solve the problems that the permeability and stability cannot be taken into account at the same time, and limit the input of membrane materials, so as to achieve the improvement of hydrogen gas permeability , small particle diameter, low powder phase formation temperature and low film sintering densification temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

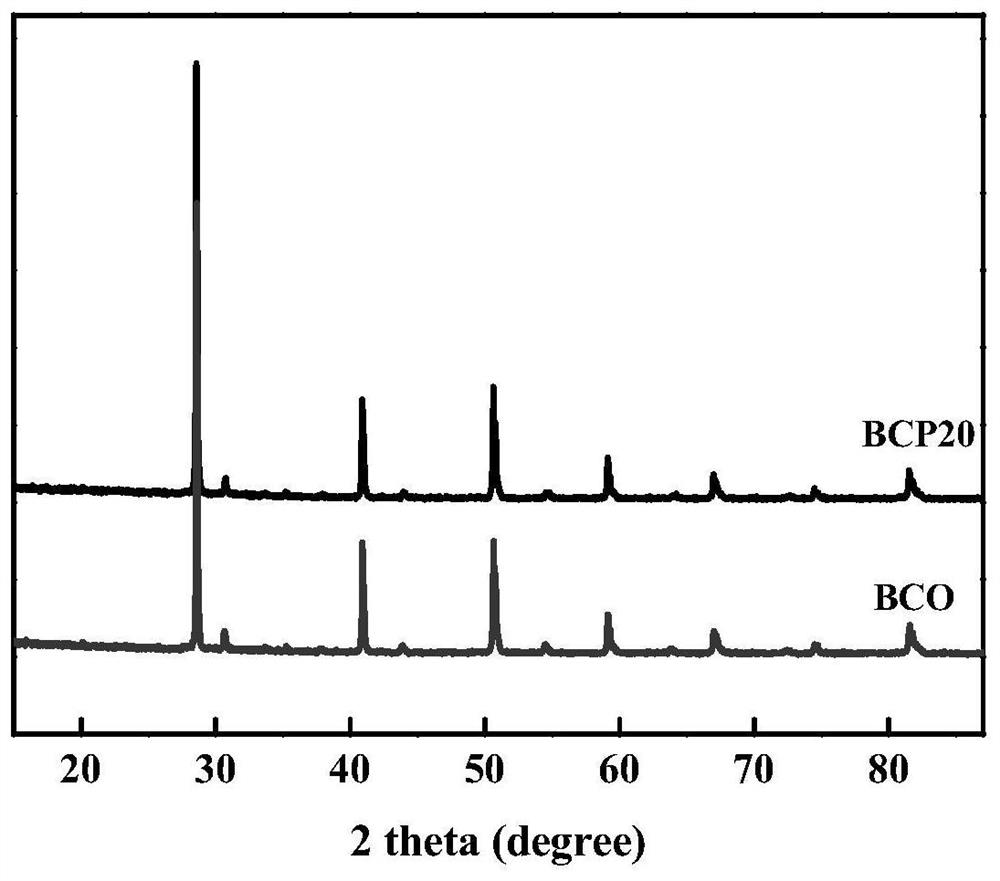

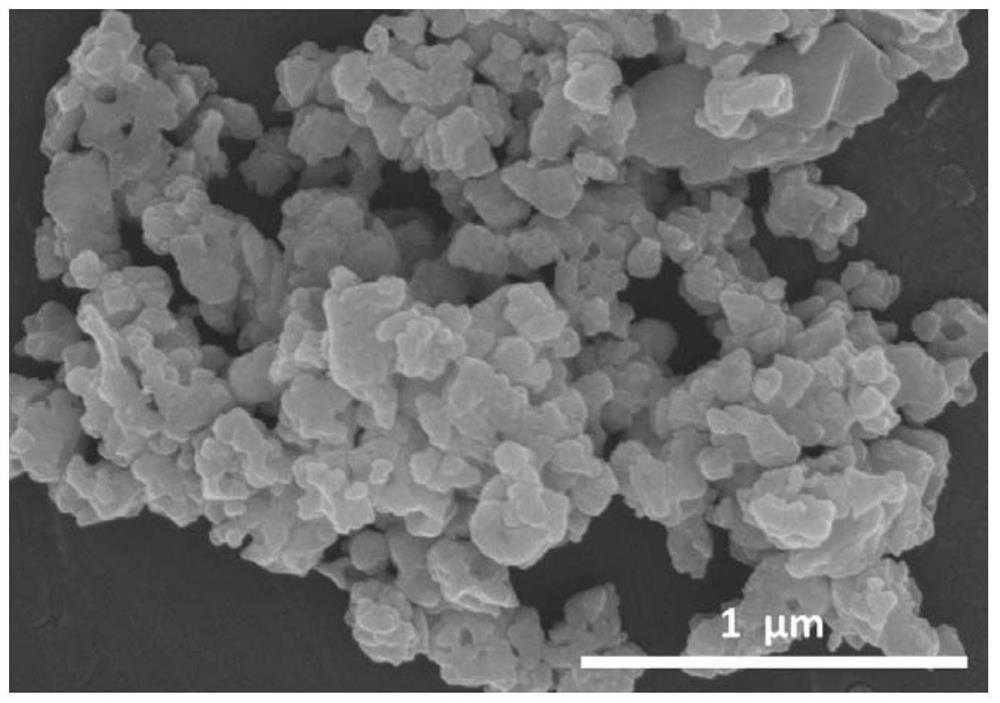

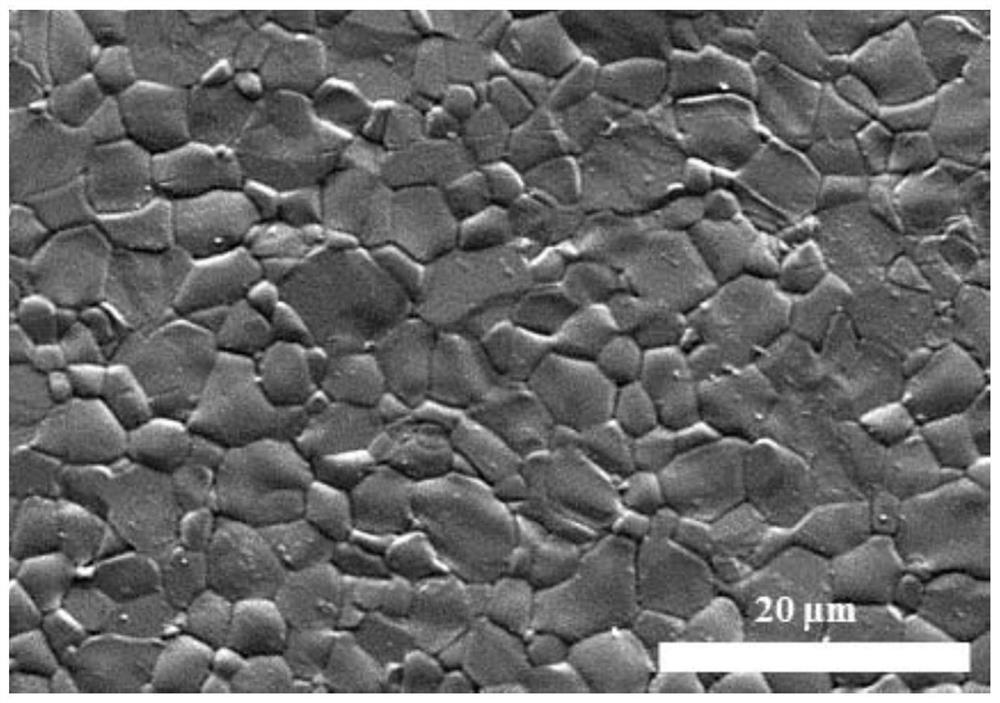

[0033] A phosphorus ion-doped perovskite-type hybrid hydrogen permeable material BaCe of the present embodiment 0.8 P 0.2 o 3-δ (δ = 0.2) (BCP20) and undoped perovskite-type hybrid hydrogen permeable material BaCeO 3-δ (δ = 0) (BCO), the preparation method comprises the following steps:

[0034] (1) Weigh BCP20 raw material: 12.91g Ba (NO 3 ) 2 , 9.33g Ce (NO 3 ) 4 ·6H 2 O, 1.14g NH 4 h 2 PO 4 Dissolve in deionized water, add 8.89g glycine to the mixture;

[0035] (2) Weigh BCO raw material: 12.91g Ba (NO 3 ) 2 , 11.66g Ce (NO 3 ) 4 ·6H 2 O was dissolved in deionized water, and 9.88g glycine was added to the mixture;

[0036] (3) Heat the nitrate mixture obtained in steps (1) and (2) to 100°C and stir for 40 hours until the solution becomes gelatinous, then put the gel in an electric furnace, heat to 350°C and roast to obtain The precursor of the powder; the powder is placed in a muffle furnace, and the temperature is kept at a rate of 2.5 ° C to 850 ° C per...

Embodiment 2

[0043] A kind of phosphorus ion-doped perovskite type mixed conductor hydrogen permeable film material Ba of the present embodiment 5.3 Zr 0.7 P 0.3 o 3-δ (δ = 0.3) (BZP30) preparation method includes the following steps:

[0044] (1) Weigh BZP30 raw material: 10.11g Ba (NO 3 ) 2 , 11.63g Zr (NO 3 ) 4 ·5H 2 O, 1.33g NH 4 h 2 PO 4 Dissolve in deionized water, add 6.72g glycine to the mixture;

[0045] (2) Heat the nitrate mixture obtained in step (1) to 250°C and stir for 32 hours until the solution takes on the form of a gel, then put the gel into an electric furnace, heat to 200°C and bake to obtain the precursor of the powder ; Put the powder in a muffle furnace, keep the temperature at a rate of 5° C. to 950° C. per minute for 12 hours, and obtain the powder BZP30.

[0046] (3) Weigh 2g of powder BZP30 and put it into a cast iron mold, keep it under a pressure of 15MPa for 5 minutes to obtain a green body; put the green body into a high-temperature muffle furna...

Embodiment 3

[0049] A kind of sulfide-doped perovskite type mixed conductor hydrogen permeable membrane material SrCe of the present embodiment 0.5 S 0.5 o 3-δ (δ =0.5) (SCS50) preparation method comprises the following steps:

[0050] (1) Weigh SCS50 raw material: 12.79g Sr (NO 3 ) 2 4H 2 O, 5.32g Ce (NO 3 ) 4 ·6H 2 O, 2.62gNH 4 h 2 SO 4 Dissolve in deionized water, add 8.05g glycine to the mixture;

[0051] (2) Heat the nitrate mixture obtained in step (1) to 350°C and stir for 25 hours until the solution becomes gel-like, then put the gel into an electric furnace, heat to 500°C and bake to obtain the precursor of the powder ; Put the powder in a muffle furnace, keep the temperature at a rate of 1° C. to 750° C. per minute for 5 hours, and obtain the powder SCS50.

[0052] (3) Weigh 0.5g of phase-forming powder SCS50 and put it into a cast iron mold, keep it under 10MPa pressure for 10 minutes to obtain a green body; put the green body into a high-temperature muffle furnace ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com