Method for removing dye pollutants by utilizing silver chromate/sulfur-doped carbon nitride Z-shaped photocatalyst

A technology of photocatalyst and carbon nitride, which is applied in the field of photocatalysis, can solve the problems of poor photocatalytic performance, fast photogenerated electron-hole recombination, and low light utilization efficiency, and achieve effective removal, convenient operation, and efficient degradation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

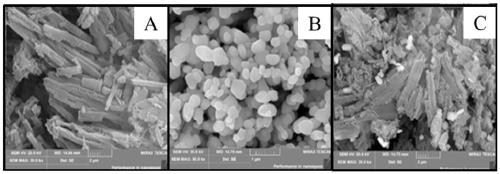

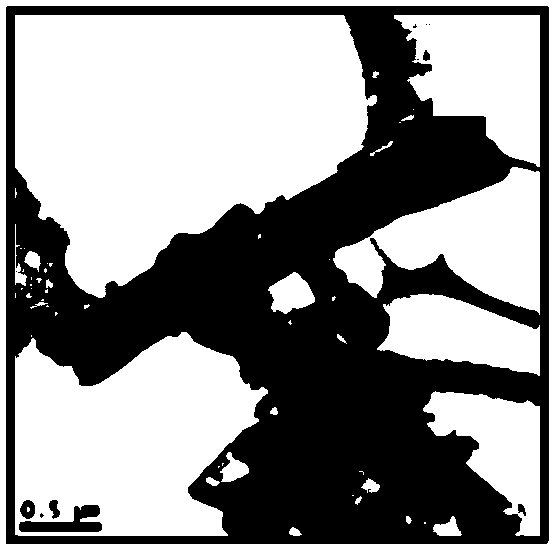

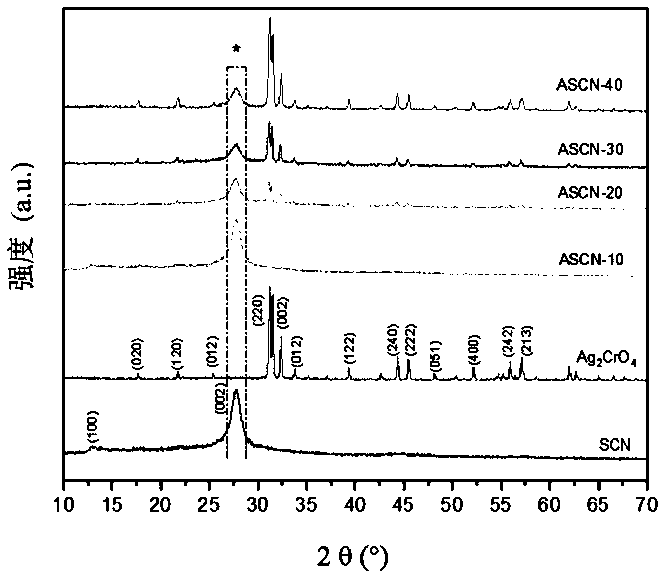

[0047] A method for removing dye pollutants by using silver chromate / sulfur-doped carbon nitride Z-type photocatalyst, specifically using silver chromate / sulfur-doped carbon nitride Z-type photocatalyst to remove dye pollutants (methyl orange ) for catalytic treatment, comprising the following steps:

[0048] Take silver chromate / sulfur-doped carbon nitride Z-type photocatalyst (ASCN-10, ASCN-20, ASCN-30, ASCN-40), sulfur-doped carbon nitride (SCN) and silver chromate (Ag 2 CrO 4 ), 20 mg each, were added to 50 mL of methyl orange (MO) solution with a concentration of 15 mg / L, mixed evenly, and methyl orange (MO) was adsorbed at 30°C and 600 rpm, and after 30 min Adsorption equilibrium is reached; the mixed solution that has reached the adsorption equilibrium is placed under a xenon lamp (power 45W, λ > 420 nm), and the photocatalytic reaction is carried out at 30°C and 600 rpm for 20 minutes to complete the treatment of methyl orange .

[0049] In this example, the silver ...

Embodiment 2

[0072] A method for removing dye pollutants by using silver chromate / sulfur-doped carbon nitride Z-type photocatalyst, specifically to investigate the effect of silver chromate / sulfur-doped carbon nitride Z-type photocatalyst on the catalytic removal of dye pollutants (methyl orange), including the following steps:

[0073] (1) Take the silver chromate / sulfur-doped carbon nitride Z-type photocatalyst (ASCN-30) and silver chromate (Ag 2 CrO 4 ), 20 mg each, were added to 50 mL of methyl orange (MO) solution with a concentration of 15 mg / L, mixed evenly, and methyl orange (MO) was adsorbed at 30°C and 600 rpm, and after 30 min Adsorption equilibrium was reached; the mixed solution that reached the adsorption equilibrium was placed under a xenon lamp (power 45W, λ > 420 nm), and the photocatalytic reaction was carried out at 30°C and 600 rpm for 20 minutes to complete the treatment of methyl orange.

[0074] (2) After the treatment in step (1), centrifuge the mixture obtained a...

Embodiment 3

[0077] A method for removing dye pollutants by using silver chromate / sulfur-doped carbon nitride Z-type photocatalyst, specifically to investigate the effect of silver chromate / sulfur-doped carbon nitride Z-type photocatalyst on the catalytic removal of dye pollutants (methyl The generation of free radicals in the process of orange), including the following steps:

[0078] (1) Take 3 parts of the silver chromate / sulfur-doped carbon nitride Z-type photocatalyst (ASCN-30) prepared in Example 1, 20 mg each, and add them to 50 mL of methyl Orange (MO) solution, mixed evenly, adsorbed methyl orange (MO) at 30 °C, 600 rpm, and reached adsorption equilibrium after 30 min.

[0079] (2) Add 0.1 mL of trihydroxyethylamine (TEOA) to the three mixtures obtained in step (1) after reaching adsorption equilibrium, which is used to capture h + ), 0.1 g p-benzoquinone (PBQ, for capturing O 2 − ) and 0.1 mL of isopropanol (IPA, for capturing OH).

[0080] (3) Put the mixtures obtained in st...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com