Hierarchical pore nano ferrierite aggregate and preparation method thereof

A ferrierite, multi-level pore technology, applied in chemical instruments and methods, molecular sieves and alkali exchange compounds, inorganic chemistry, etc., can solve the problems of low silicon and aluminum samples, large crystals, harsh crystallization conditions, etc., and achieve improved crystallization. degree, high specific surface area, and the effect of shortening the crystallization time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] The present invention also provides a method for preparing the hierarchically porous nano-ferrierite aggregate, which is characterized in that the method comprises the following steps:

[0027] (1) Fully mix the silicon source and template to obtain mixture A;

[0028] (2) Fully mix aluminum source, alkali source, water source and additives to obtain mixture B;

[0029] (3) Add the mixture B dropwise to the mixture A, and mix evenly to obtain a gel;

[0030] (4) The obtained gel is subjected to segmental dynamic crystallization, and after the crystallization is completed, the multi-level porous nano ferrierite aggregates are obtained by suction filtration, drying and roasting.

[0031] In one embodiment of the present invention, the silicon source in step (1) is water glass, silica sol (a solution with a concentration of 20-35% by weight), tetraethyl orthosilicate, white carbon black, or a mixture thereof.

[0032] In one embodiment of the present invention, the alkal...

Embodiment 1

[0058] 240g silica sol (concentration is the aqueous solution of 25% by mass) and 18g ethylenediamine are fully mixed, obtain mixture A; 6.56g sodium metaaluminate, 15.2g sodium hydroxide, 540g deionized water and 4.2g sodium fluoride are fully mixed Mix and mix for 60 minutes to obtain mixture B; add mixture B to mixture A drop by drop, and stir continuously for 3 hours until the gel is mixed evenly. The gel molar ratio is: SiO 2 : Al 2 o 3 :R:NaF:Na 2 O:H 2 O is 1:0.04:0.3:0.1:0.19:40; wherein R is ethylenediamine. Then the gel was crystallized at 70°C for 12 hours, and then crystallized at 170°C for 2 days at a rotation speed of 100 rpm. After the crystallization was completed, the hierarchical porous nano-ferrierite aggregate was obtained by suction filtration, drying, and roasting product.

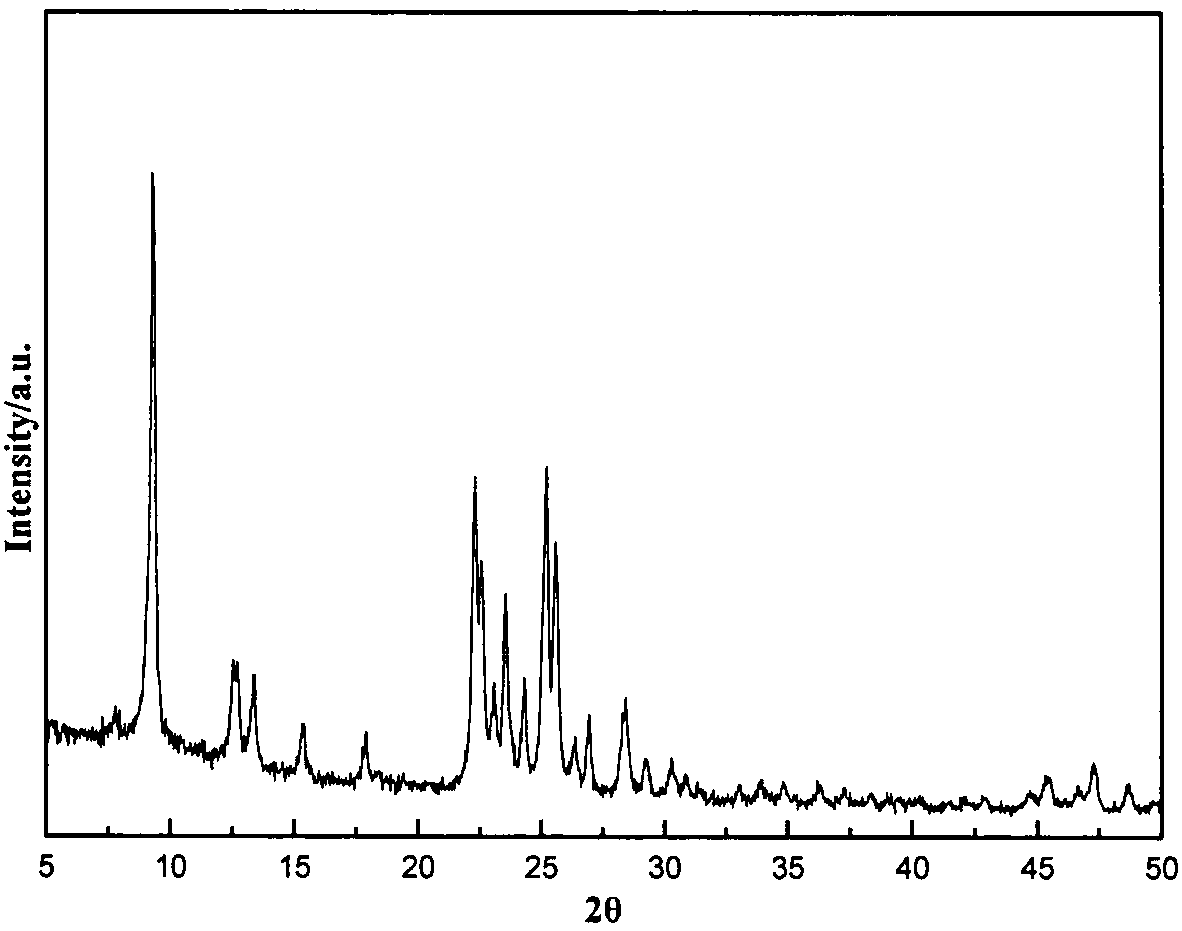

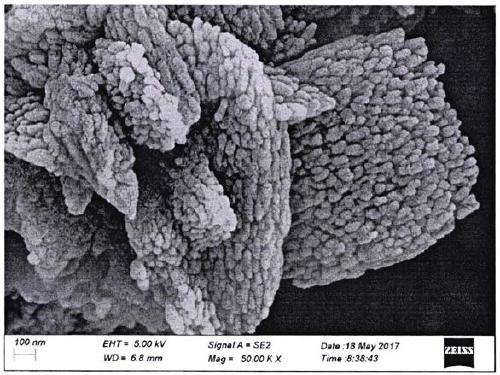

[0059] figure 1 Be the XRD spectrogram of embodiment 1 gained molecular sieve, from figure 1 It can be seen that the molecular sieve obtained in this example is a pure-phase f...

Embodiment 2

[0061] 240g of silica sol (aqueous solution with a concentration of 25% by mass) and 23.7g of pyridine were fully mixed to obtain mixture A; 1.64g of sodium metaaluminate, 15.2g of sodium hydroxide, 540g of deionized water and 4.2g of sodium fluoride were fully mixed , and mixed for 50 minutes to obtain a mixture B; the mixture B was added dropwise to the mixture A, and stirred continuously for 3 hours until the gel was mixed evenly. The gel molar ratio is: SiO 2 : Al 2 o 3 :R:NaF:Na 2 O:H 2 O is 1:0.01:0.3:0.1:0.19:40; wherein R is pyridine. Then the gel was crystallized at 70°C for 12 hours, and then crystallized at 170°C for 2 days at a rotation speed of 100 rpm. After the crystallization was completed, the hierarchical porous nano-ferrierite aggregate was obtained by suction filtration, drying, and roasting product.

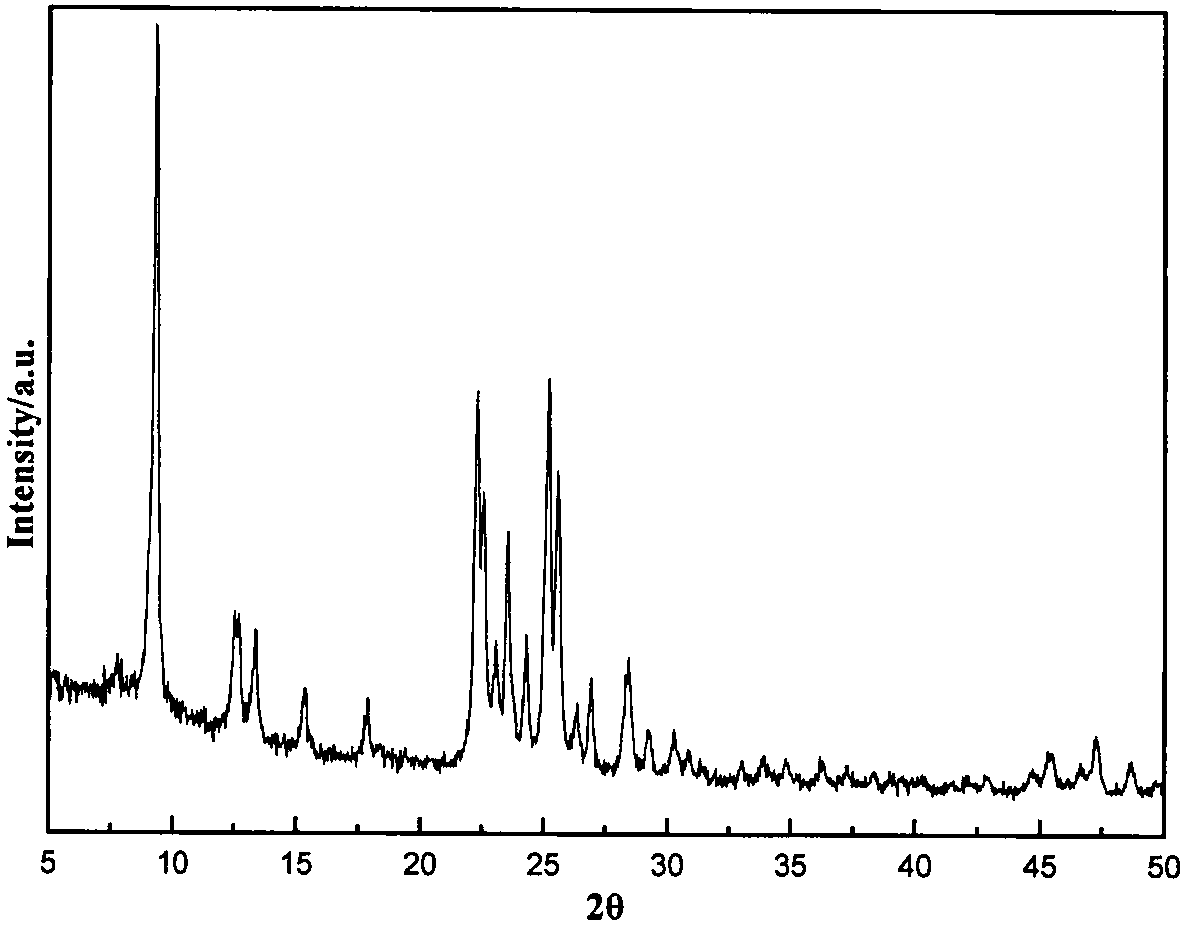

[0062] image 3 Be the XRD spectrogram of embodiment 2 gained molecular sieves, from image 3 It can be seen that the molecular sieve obtained in thi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| surface area | aaaaa | aaaaa |

| crystallinity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com