Preparation method for tungsten hexafluoride and reactor thereof

A tungsten hexafluoride and reactor technology, which is applied in the field of tungsten hexafluoride preparation, can solve problems such as unsuitable carbon-containing materials, and achieve the effects of compact structure, stable reaction process, and high utilization rate of fluorine gas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

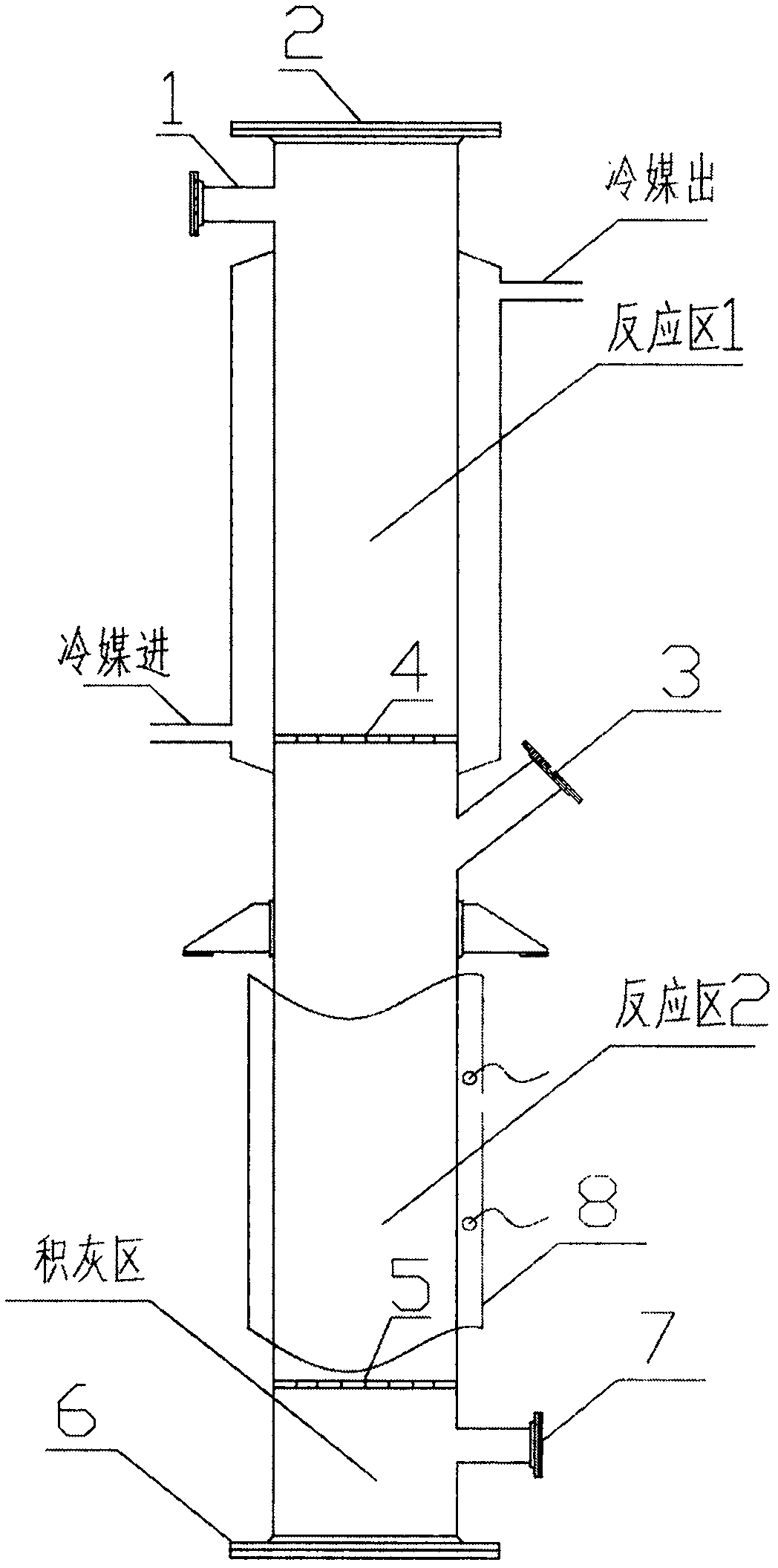

Image

Examples

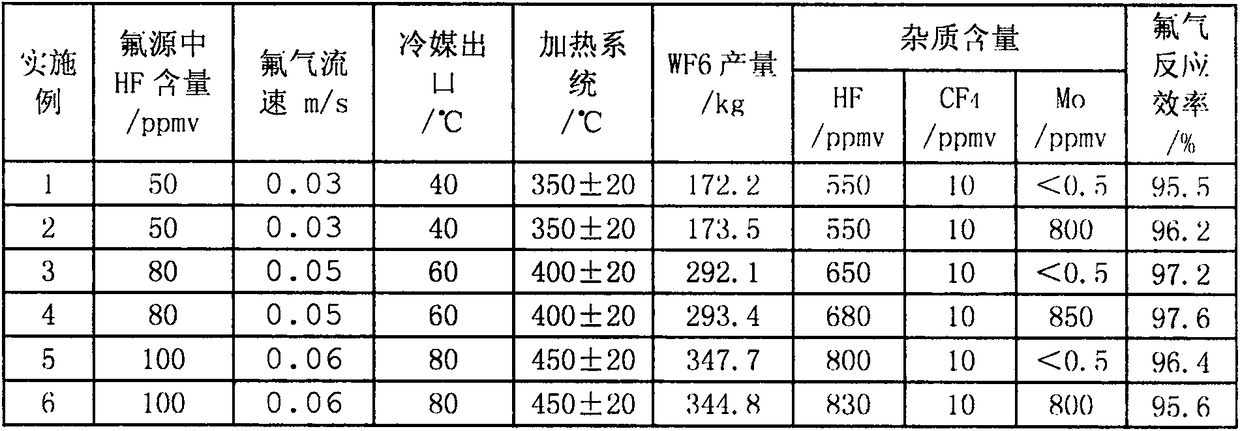

Embodiment 1

[0026] The reactor is made of Monel material, the inner diameter of the reactor is 100mm, and the length of the two-stage reactor is 1000mm. High-purity tungsten blocks are used as raw materials, the tungsten content is greater than 99.5%, the length is 40-50mm, and the diameter is 10mm. After drying, add 0.5kg of petroleum coke to the reactor, and the fluorine gas is obtained by electrolytic purification, containing about 50ppmv of HF and other impurities, and the fluorine gas is continuously introduced at a superficial gas velocity of 0.03m / s In reaction zone 1, the average residence time is 100s. Reaction zone 2 is filled with 5kg of nickel wire and 50kg of tungsten block, and the outlet temperature of cooling water is controlled at 40°C. Reaction zone 2 is controlled by an electric heating system to control the temperature in the reactor to 350±20°C. Analyze the composition of crude gas products generated by the reaction. The device was operated for 48 hours, the reactio...

Embodiment 2

[0028] The reactor is the same as in Example 1, and no metal catalyst is added in the reactor 2, and the others are the same as in Example 1. A total of 173.5 kg of crude material is collected.

Embodiment 3

[0030] The reactor is made of nickel material, and the structure is the same as in Example 1. High-purity tungsten blocks are used as raw materials, the tungsten content is greater than 99.5%, the length is 40-50mm, and the diameter is 10mm. After drying, add 0.5kg of charcoal to the reactor, fluorine gas is obtained by electrolytic purification, contains about 80ppmv of HF and other impurities, and continuously feeds fluorine gas into the reaction at a superficial gas velocity of 0.05m / s Zone 1, the average residence time is 80s. The reaction zone 2 is filled with 1kg of copper wire and 100kg of tungsten blocks, and the outlet temperature of the cooling water is controlled at 60°C. The reaction zone 2 is controlled by an electric heating system to control the temperature inside the reactor at 400±20°C. Analyze the composition of crude gas products generated by the reaction. The device was operated for 48 hours, the reaction was stopped, and a total of 292.1 kg of crude mate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com