Method for preparing vorapaxar intermediate

An intermediate and equivalent technology, applied in the field of preparation of Vorapaxa intermediate VRPX-200, can solve the problems of unstable yield, high safety hazard, harsh reaction conditions, etc., and achieves low safety risk, stable yield, mild response

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

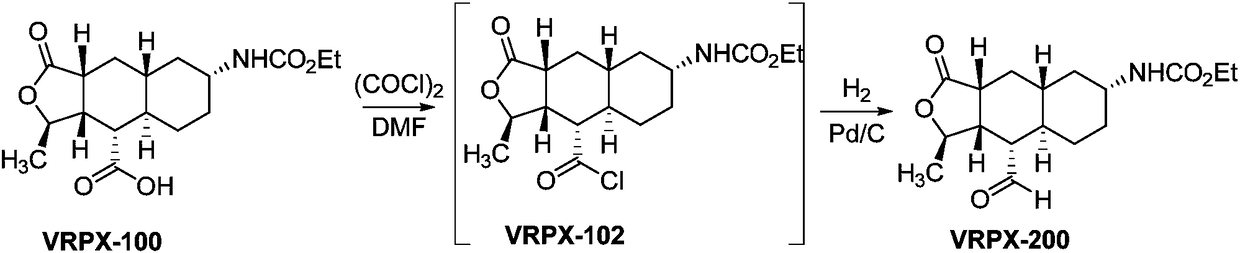

Method used

Image

Examples

Embodiment 1

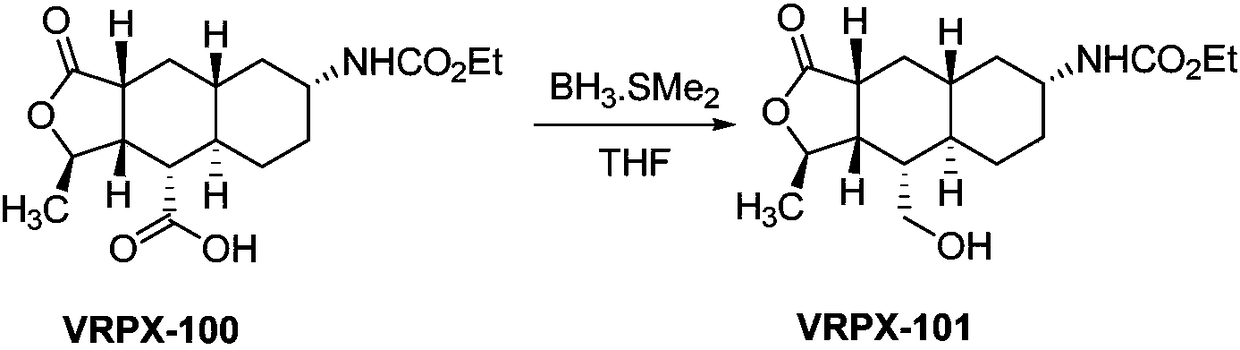

[0025] Step-1: Preparation of intermediate VRPX-101

[0026] Compound VRPX-100 (1.5Kg, 442mmol) was dissolved in 9.0L anhydrous tetrahydrofuran, cooled to -5~0°C, and borane dimethyl sulfide (504g, 663mmol) was added dropwise to control the internal temperature at -5~0°C, React for 5-10 hours; TLC monitors that the reaction of compound VRPX-100 is complete, add 400 grams of methanol, quench the reaction, and distill it under vacuum to dryness, and add 3.0L of anhydrous tetrahydrofuran to the remaining concentrate, and distill it under vacuum To dryness, the residue was directly put into the next reaction.

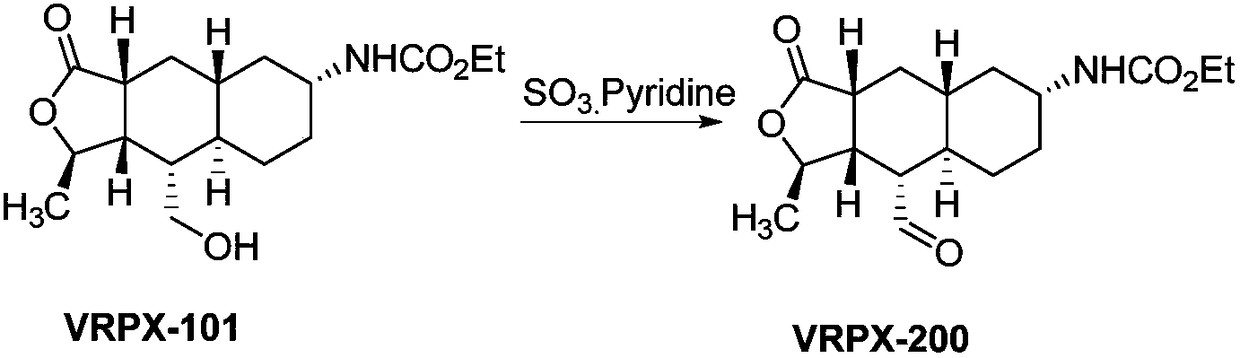

[0027] Step-2: Preparation of intermediate VRPX-200

[0028] Dissolve the crude product of VRPX-101 from the previous step in 4.5L DMSO, at room temperature 20-25°C, add pyridine sulfur trioxide (915g, 575mmol) in batches, stir for about 2-3 hours, TLC shows that the substrate is complete, add 9.0L to purify Quench the reaction with water, add 4.5L ethyl acetate for extra...

Embodiment 2

[0030] Step-1: Preparation of intermediate VRPX-101

[0031] Dissolve compound VRPX-100 (15g, 4.4mmol) in 90mL of anhydrous tetrahydrofuran, lower the temperature at -5~0°C, add borane dimethyl sulfide (3.3g 4.4mmol) dropwise, react at -5~0°C for 15~ 20 hours; TLC showed that most of the reaction of compound VRPX-100 was complete, adding 4g of methanol, quenching the reaction, distilling under vacuum and reducing to dryness, and adding 30mL of anhydrous tetrahydrofuran to the remaining concentrate, distilling under vacuum and reducing to dryness, the remaining directly into the next reaction.

[0032] Step-2: Preparation of intermediate VRPX-200

[0033] Dissolve the crude product of VRPX-101 from the previous step in 45mL DMSO, at room temperature 20-25°C, add pyridine sulfur trioxide (7.1g) in batches, stir for about 2-3 hours, TLC shows that most of the substrates have reacted completely, add 90mL to purify Quench the reaction with water, add 45 mL of ethyl acetate for ex...

Embodiment 3

[0035] Step-1: Preparation of intermediate VRPX-101

[0036] Dissolve compound VRPX-100 (15g, 4.4mmol) in 90mL of anhydrous tetrahydrofuran, lower the temperature to -5~0°C, add borane dimethyl sulfide (10.0g 13.2mmol) dropwise, and react at -5~0°C for 3~ 6 hours; TLC showed that the compound VRPX-100 was completely consumed. Add 4g of methanol to quench the reaction. Distill in vacuum to dryness. For the remaining concentrate, add 30 mL of anhydrous tetrahydrofuran and distill in vacuum to dryness. The residue was directly into the next reaction.

[0037] Step-2: Preparation of intermediate VRPX-200

[0038] Dissolve the crude VRPX-101 from the previous step in 45mL DMSO, at room temperature 20-25°C, add sulfur trioxide pyridine (14.2g) in batches, stir for about 2-3 hours, TLC shows that the reaction of the substrate is complete, add 90mL purified water to quench Inhibit the reaction, add 45mL ethyl acetate for extraction, separate the layers, extract the aqueous phase twi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com