Environmentally friendly acrylic resin and preparation method thereof

An acrylic resin and an environment-friendly technology, applied in the field of environment-friendly acrylic resin and its preparation and processing of nail polish, can solve the problems of low solid content of nail polish, toxicity to the human body and the environment, etc., and achieve good hardness, good hydrophobicity, organic The effect of less solvent

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

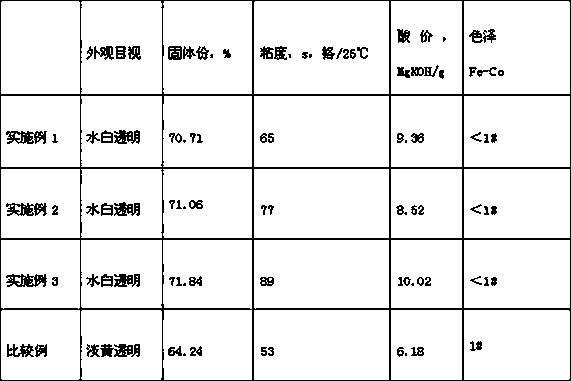

Embodiment 1

[0052] A kind of environment-friendly acrylic resin of the present embodiment comprises following raw material:

[0053] Bottom material: 3 grams of E10P material, 3 grams of amyl acetate, 13 grams of n-butyl acetate

[0054] Mixed dripping material: 1.5 grams of methacrylic acid, 5 grams of methyl methacrylate, 16 grams of styrene, 5.5 grams of tert-butyl acrylate, 3.5 grams of hydroxyethyl methacrylate, 5.5 grams of 2-hydroxypropyl acrylate, methyl 2 g of n-butyl acrylate, 4 g of n-butyl acrylate, 1.8 g of dicumyl peroxide, 0.8 g of 1,1-bis(tert-butylperoxy)cyclohexane, and 1 g of n-butyl acetate;

[0055] Initiator 1: 0.10 g of 1,1-bis(tert-butylperoxy)cyclohexane, 1 g of n-butyl acetate;

[0056] Initiator 2: 0.10 g of 1,1-bis(tert-butylperoxy)cyclohexane, 1 g of n-butyl acetate;

[0057] Diluent: 2 grams of n-butyl acetate;

[0058] A preparation method of environment-friendly acrylic resin, comprising the following steps:

[0059] 1. Add 3 grams of E10P material, 3 g...

Embodiment 2

[0065] A kind of environment-friendly acrylic resin of the present embodiment comprises following raw material:

[0066] Bottom material: 4.5 grams of E10P material, 4 grams of amyl acetate, 17 grams of n-butyl acetate

[0067] Mixed dripping material: 2.3 grams of methacrylic acid, 7.5 grams of methyl methacrylate, 21 grams of styrene, 7.5 grams of tert-butyl acrylate, 5 grams of hydroxyethyl methacrylate, 8.5 grams of 2-hydroxypropyl acrylate, methyl 3 g of n-butyl acrylate, 6 g of n-butyl acrylate, 2.0 g of dicumyl peroxide, 1.0 g of 1,1-bis(tert-butyl peroxy)cyclohexane, and 1 g of n-butyl acetate;

[0068] Initiator 1: 0.15 g of 1,1-bis(tert-butylperoxy)cyclohexane, 1.5 g of n-butyl acetate;

[0069] Initiator 2: 0.15 g of 1,1-bis(tert-butylperoxy)cyclohexane, 1.5 g of n-butyl acetate;

[0070] Diluent: 3 grams of n-butyl acetate;

[0071] A preparation method of environment-friendly acrylic resin, comprising the following steps:

[0072] 1. Add 4.5 grams of E10P mate...

Embodiment 3

[0078] A kind of environment-friendly acrylic resin of the present embodiment comprises following raw material:

[0079] Bottom material: 6.0 grams of E10P material, 5 grams of amyl acetate, 20 grams of n-butyl acetate

[0080] Mixed dripping material: 3 grams of methacrylic acid, 10 grams of methyl methacrylate, 25 grams of styrene, 9.5 grams of tert-butyl acrylate, 6.0 grams of hydroxyethyl methacrylate, 9.5 grams of 2-hydroxypropyl acrylate, methyl 4.0 g of n-butyl acrylate, 7.0 g of n-butyl acrylate, 2.2 g of dicumyl peroxide, 1.1 g of 1,1-bis(tert-butyl peroxy)cyclohexane, and 1 g of n-butyl acetate;

[0081] Initiator 1: 0.2 g of 1,1-bis(tert-butylperoxy)cyclohexane, 2.0 g of n-butyl acetate;

[0082] Initiator 2: 0.2 g of 1,1-bis(tert-butylperoxy)cyclohexane, 2.0 g of n-butyl acetate;

[0083] Diluent: 4 grams of n-butyl acetate;

[0084] A preparation method of environment-friendly acrylic resin, comprising the following steps:

[0085] 1. Add 6.0 grams of E10P mat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com