Preparation method of reflection type acrylic acid outer wall emulsion and reflection type acrylic acid outer wall emulsion

An acrylic and reflective technology, applied in the direction of reflective/signal coatings, coatings, paints containing biocides, etc., can solve the problems of poor storage stability and inconvenient storage, and achieve consistent structure, high bonding fastness, and washability good rubbing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

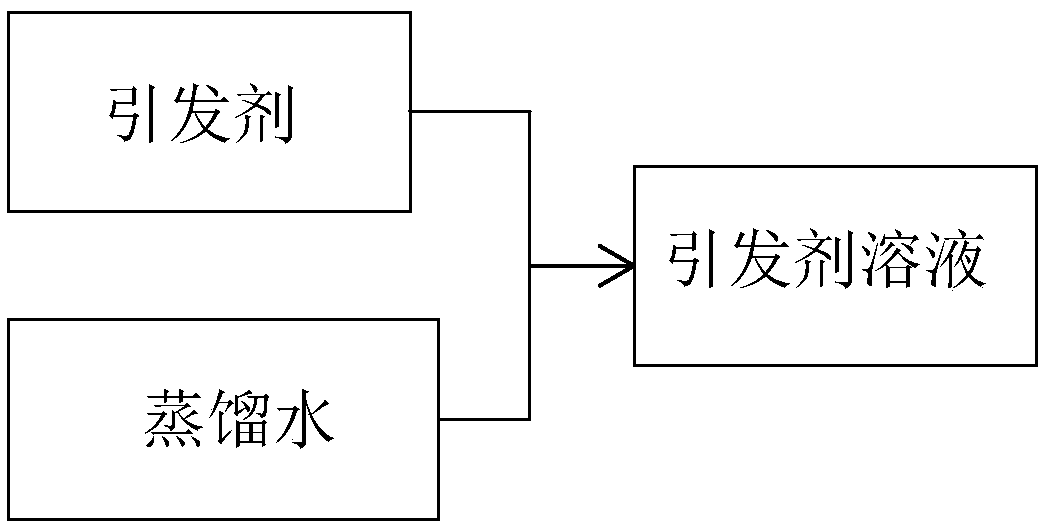

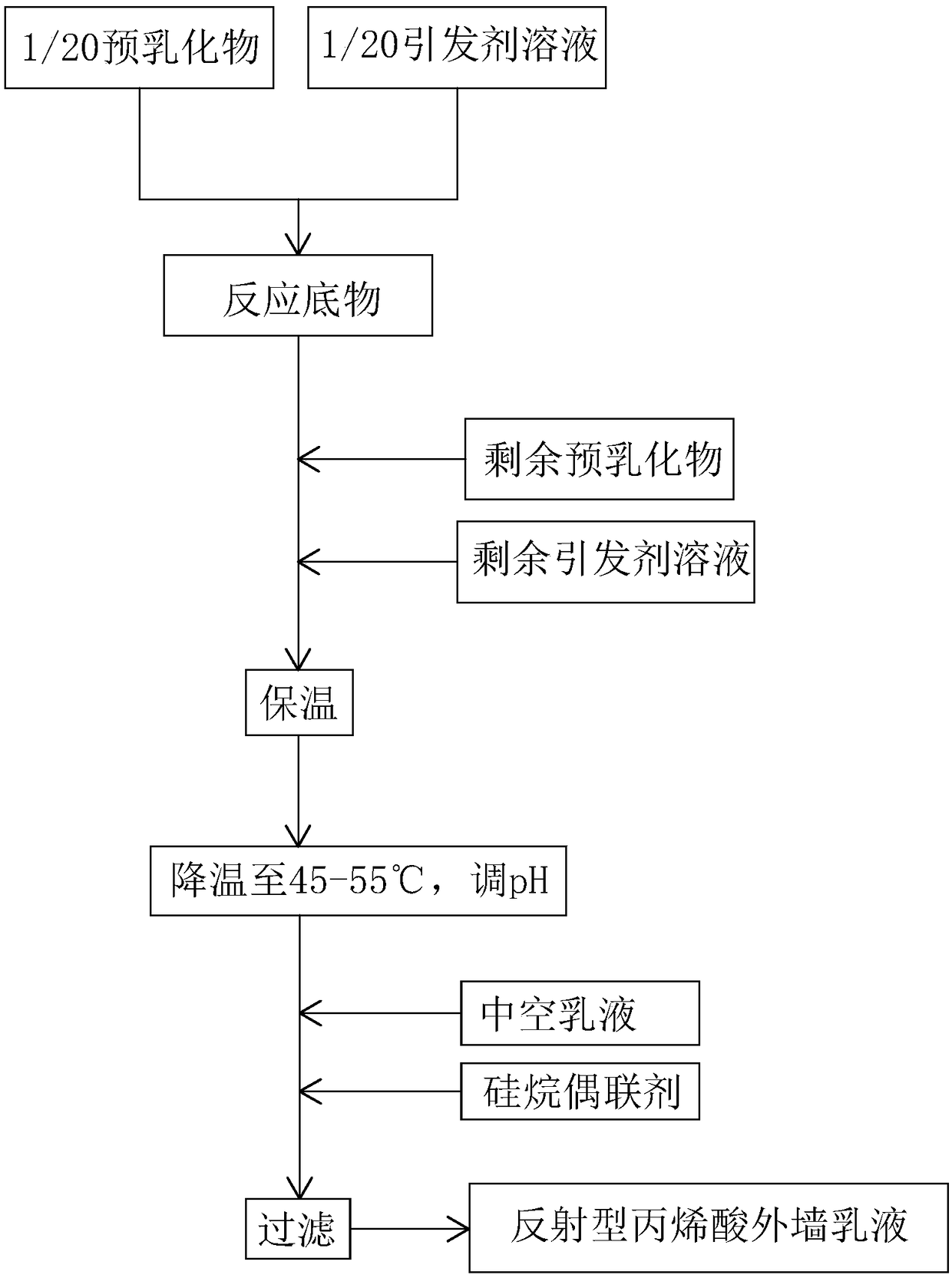

[0054] A method for preparing reflective acrylic exterior wall emulsion, which comprises the steps of preparing pre-emulsion, preparing initiator solution and emulsification polymerization.

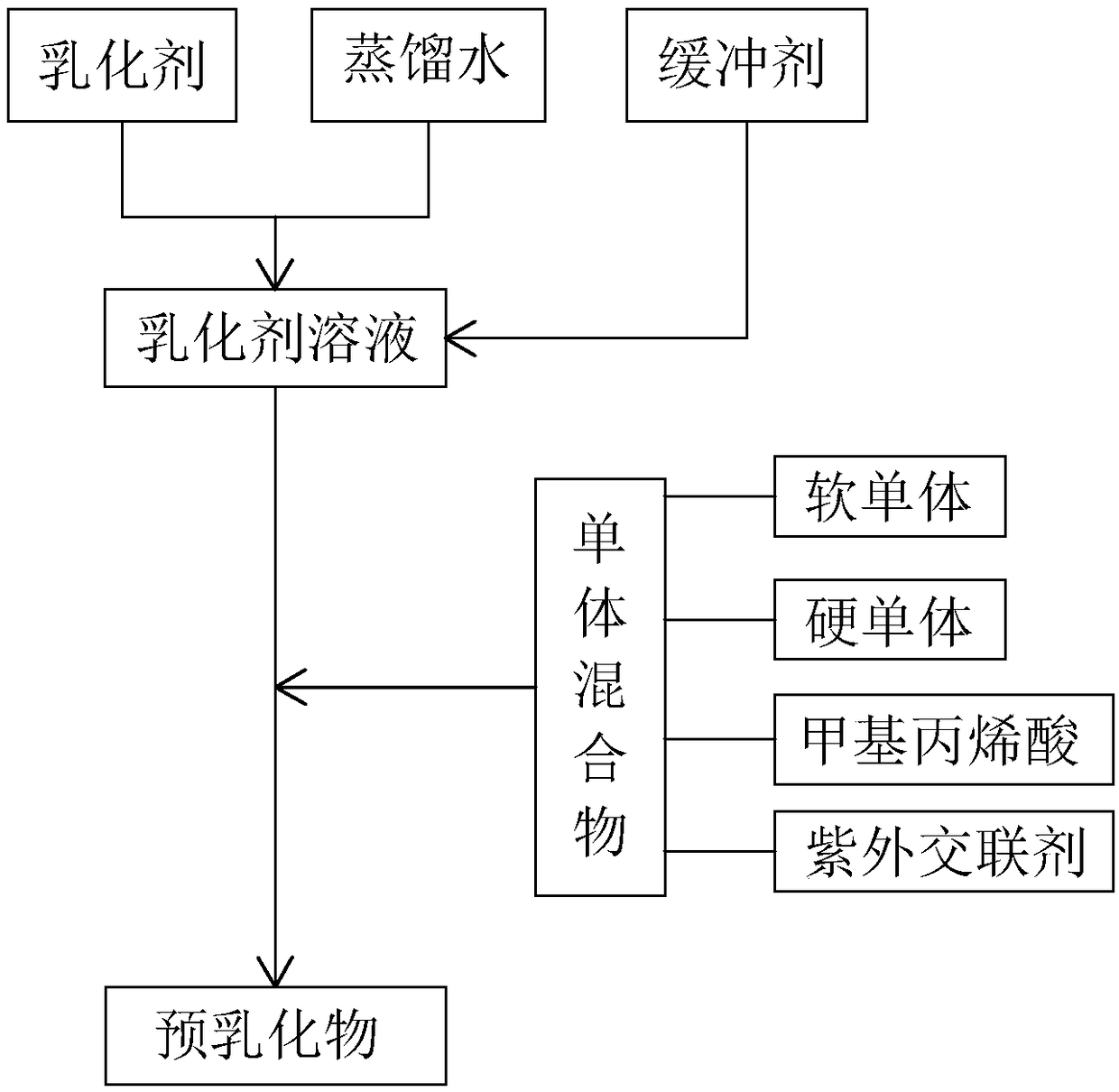

[0055] The preparation process of pre-emulsion is as follows: figure 1 shown. Weigh 1.0 part of emulsifier according to parts by weight, add 45 parts of distilled water, and stir evenly to prepare emulsifier solution. The emulsifier is preferably a composite emulsifier. In this example, nonylphenol polyoxyethylene ether, octylphenol polyoxyethylene ether and sodium lauryl sulfate are mixed in a mass ratio of 5:2:1. After the emulsifier is completely dissolved, an appropriate amount of buffer such as sodium bicarbonate can be added to the emulsifier solution, and stirred until it is completely dissolved.

[0056] The monomer mixture is formed by mixing the polymerized monomer and the ultraviolet crosslinking agent, and is added to the emulsifier solution by gradually dropping. Polymeriz...

Embodiment 2-5

[0066] Examples 2-5 all relate to a preparation method of reflective acrylic exterior wall emulsion, and the difference from Example 1 is that the dosage of each component is different, as shown in the following table:

[0067] Table 1.

[0068]

[0069] The emulsifier is formed by mixing nonylphenol polyoxyethylene ether, octylphenol polyoxyethylene ether and sodium lauryl sulfate in a mass ratio of 5:2:1.

Embodiment 2

[0071] In Example 2, the stirring rate after adding the monomer mixture into the emulsifier solution was 450 rpm; the stirring rate when adding the remaining part of the pre-emulsion and the initiator solution dropwise into the reaction substrate was 235 rpm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com