Silicone rubber composite material and preparation method thereof

A technology of composite materials and silicone rubber, which is applied in the field of silicone rubber composite materials and its preparation, to achieve the effects of reasonable formula, excellent corrosion resistance, and easy industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

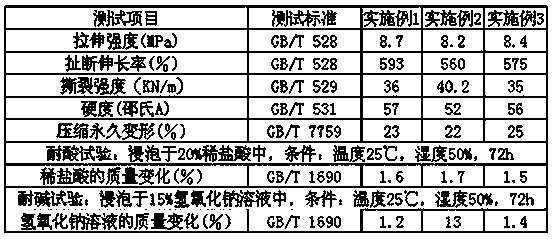

Embodiment 1

[0033] A silicone rubber composite material provided in this embodiment is composed of the following components in parts by weight: 42 parts of silicone rubber, 15 parts of cashew oil modified phenol-formaldehyde resin, 15 parts of filler, 12 parts of carbon fiber, hydroxypropyl 3 parts of silicone oil, 3 parts of chloromethoxy fatty acid methyl ester, 2 parts of ethylene bis stearic acid amide, 1 part of hexamethylenetetramine, 6 parts of corrosion resistance agent, 0.25 part of vulcanizing agent, 0.75 part of coupling agent .

[0034] Wherein, the silicone rubber is one or two kinds of methyl vinyl silicone rubber and fluorosilicone rubber. In this embodiment, methyl vinyl silicone rubber and fluorosilicone rubber are selected in a weight ratio of 1:1; The filler is a mixture of nano-alumina, precipitated white carbon black and nano-calcium carbonate, and its weight ratio is 1:3:1; the carbon fiber is graphitized carbon fiber chopped strands, with a density of 0.1~1.8g / cm 3...

Embodiment 2

[0042] A silicone rubber composite material provided in this embodiment is composed of the following components in parts by weight: 46 parts of silicone rubber, 12 parts of cashew nut oil modified phenol-formaldehyde resin, 20 parts of filler, 10 parts of carbon fiber, hydroxypropyl 1 part of silicone oil, 4 parts of chloromethoxy fatty acid methyl ester, 1 part of ethylene bis stearic acid amide, 1.4 parts of hexamethylenetetramine, 4 parts of corrosion resistance agent, 0.15 part of vulcanizing agent, 0.45 part of coupling agent .

[0043] A kind of preparation method of silicone rubber composite material provided by the present embodiment comprises the following steps:

[0044] (1) Dosing each component according to the above-mentioned parts by weight;

[0045] (2) Add silicone rubber, cashew nut oil modified phenol-formaldehyde resin, carbon fiber, filler and coupling agent into the internal mixer for mixing, the mixing temperature is 45°C, and the mixing time is 3min; th...

Embodiment 3

[0050]A silicone rubber composite material provided in this embodiment is composed of the following components in parts by weight: 38 parts of silicone rubber, 18 parts of cashew nut oil modified phenol-formaldehyde resin, 12 parts of filler, 15 parts of carbon fiber, hydroxypropyl 2 parts of silicone oil, 5 parts of chloromethoxy fatty acid methyl ester, 3 parts of ethylene bis stearic acid amide, 0.7 parts of hexamethylenetetramine, 5 parts of corrosion resistance agent, 0.1 part of vulcanizing agent, 1.2 parts of coupling agent .

[0051] A kind of preparation method of silicone rubber composite material provided by the present embodiment comprises the following steps:

[0052] (1) Dosing each component according to the above-mentioned parts by weight;

[0053] (2) Add silicone rubber, cashew nut oil modified phenol-formaldehyde resin, carbon fiber, filler and coupling agent into the internal mixer for mixing, the mixing temperature is 35°C, and the mixing time is 5min; th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com