Conductive coating composition

A conductive coating and composition technology, applied in conductive coatings, anti-corrosion coatings, fire-resistant coatings, etc., can solve problems such as poor salt corrosion resistance, and achieve the effects of stable electrical conductivity, easy storage, and low resistivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0070]The present embodiment relates to a conductive coating composition and a preparation method thereof, the coating is composed of the following raw materials by weight:

[0071] 46 parts of acrylic resin;

[0072] 20 parts of Darma resin;

[0073] 2 parts of gallium arsenide;

[0074] Dead Sea mud 6.5 servings;

[0075] 4 parts of perovskite powder;

[0076] 1 part of cellulose acetate butyrate;

[0077] 1.5 parts of brucite chopped fiber;

[0078] 0.3 part of diethylene glycol dibenzoate;

[0079] 9 parts of dimethyl sulfoxide;

[0080] 3 parts of snail mucus;

[0081] 0.65 part of accelerator;

[0082] 0.95 part of cross-linking agent;

[0083] 0.5 part of coupling agent;

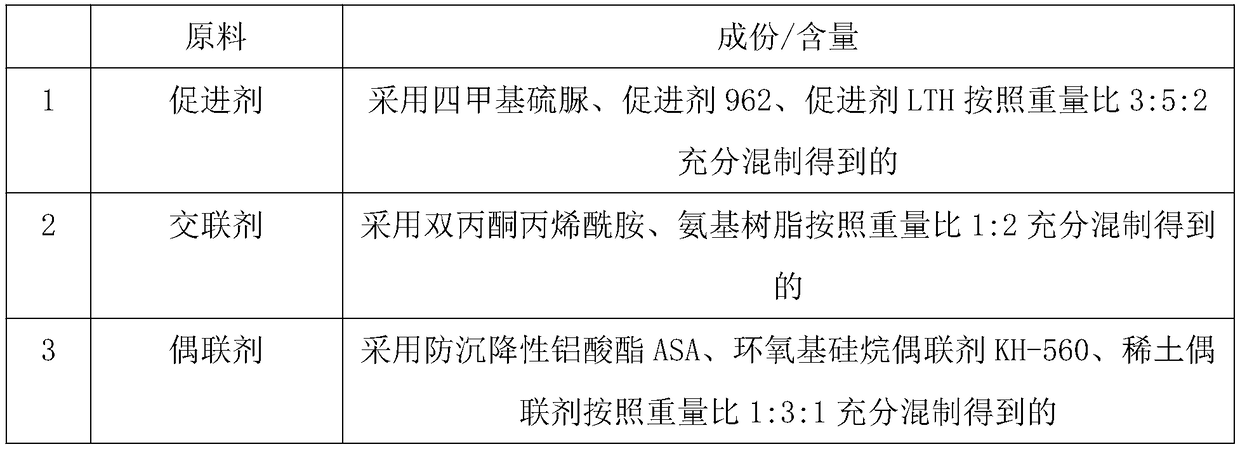

[0084] The selection and preparation of accelerator, cross-linking agent and coupling agent in the present embodiment are shown in Table 1 below:

[0085] Table 1

[0086]

[0087] The preparation method of the coating of the present embodiment is carried out according to the following ...

Embodiment 2

[0093] The present embodiment relates to a conductive coating composition and a preparation method thereof, the coating is composed of the following raw materials by weight:

[0094] 48 parts of acrylic resin;

[0095] 21 parts of Darma resin;

[0096] GaAs 2.4 parts;

[0097] Dead Sea mud 7 parts;

[0098] 4.5 parts of perovskite powder;

[0099] 1.2 parts of cellulose acetate butyrate;

[0100] 1.8 parts of brucite chopped fiber;

[0101] 0.35 part of diethylene glycol dibenzoate;

[0102] 10 parts of dimethyl sulfoxide;

[0103] 3.5 servings of snail mucus;

[0104] 0.7 part of accelerator;

[0105] 1.05 parts of cross-linking agent;

[0106] 0.55 part of coupling agent;

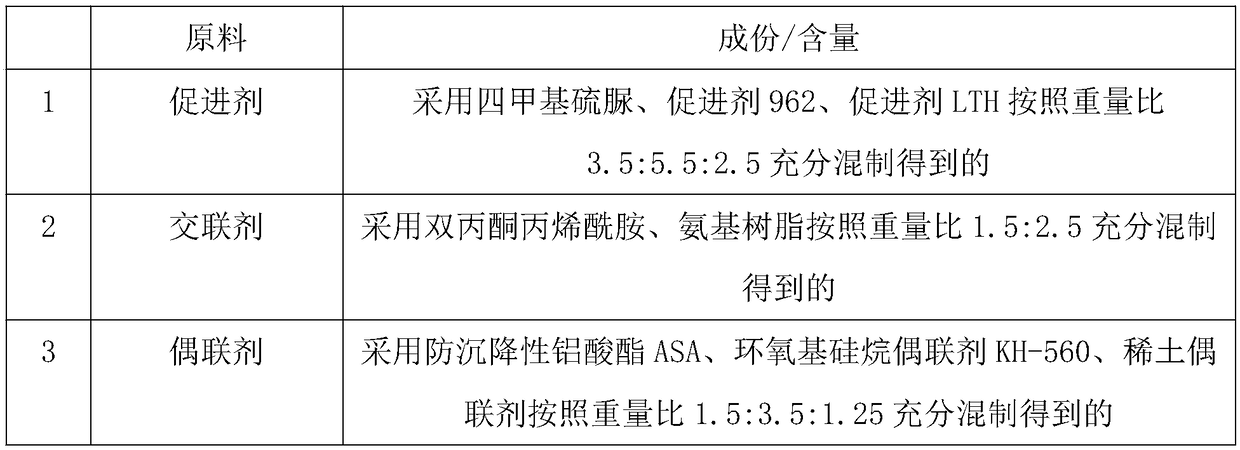

[0107] The selection and preparation of accelerator, cross-linking agent and coupling agent in the present embodiment are shown in Table 2 below:

[0108] Table 2

[0109]

[0110] The preparation method of the coating of the present embodiment is carried out according to the following step...

Embodiment 3

[0116] The present embodiment relates to a conductive coating composition and a preparation method thereof, the coating is composed of the following raw materials by weight:

[0117] 49 parts of acrylic resin;

[0118] 22 parts of Darma resin;

[0119] GaAs 2.7 parts;

[0120] Dead Sea mud 7.5 servings;

[0121] 5 parts of perovskite powder;

[0122] 1.5 parts of cellulose acetate butyrate;

[0123] 2 parts of brucite chopped fiber;

[0124] 0.4 part of diethylene glycol dibenzoate;

[0125] 11 parts of dimethyl sulfoxide;

[0126] 4 parts of snail mucus;

[0127] 0.75 part of accelerator;

[0128] 0.15 part of cross-linking agent;

[0129] 0.6 part of coupling agent;

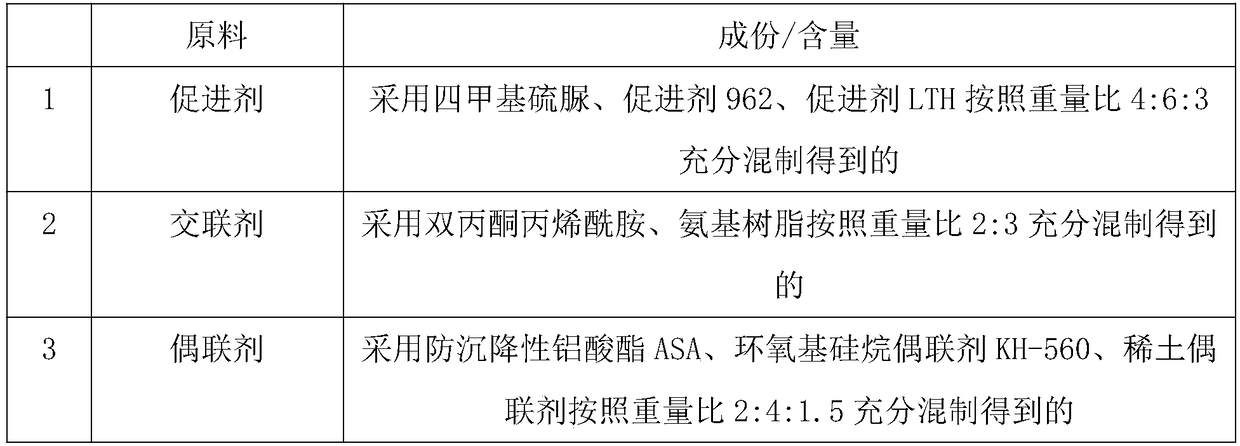

[0130] The selection and preparation of accelerator, cross-linking agent and coupling agent in the present embodiment are shown in Table 3 below:

[0131] table 3

[0132]

[0133] The preparation method of the coating of the present embodiment is carried out according to the following steps:

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com