Spraying coating for aluminum-plated silicon wire sink roller and preparation method thereof

A sunken roller and coating technology, which is applied in the direction of coating, metal material coating process, melt spraying, etc., can solve the problems of surface performance and service life reduction of aluminum-silicon wire sunken rollers, and achieve good anti-sticking aluminum slag performance , High powder utilization rate, cost-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] This embodiment includes the following steps:

[0027] 1. Pretreatment before spraying of sinking roller

[0028] (1) Derust and decontaminate the surface of the sinking roller until the surface of the roller is smooth;

[0029] (2) For the sandblasting treatment on the surface of the sunken roller after the above step (1) treatment, use a direct shot sandblasting machine, carry out sandblasting and roughening treatment on the surface of the sunken roller by the mechanical hand-held sandblasting gun in the sandblasting room, and use 20 ~60 mesh white corundum sand, the surface roughness of the roller reaches Ra3~8 after sandblasting.

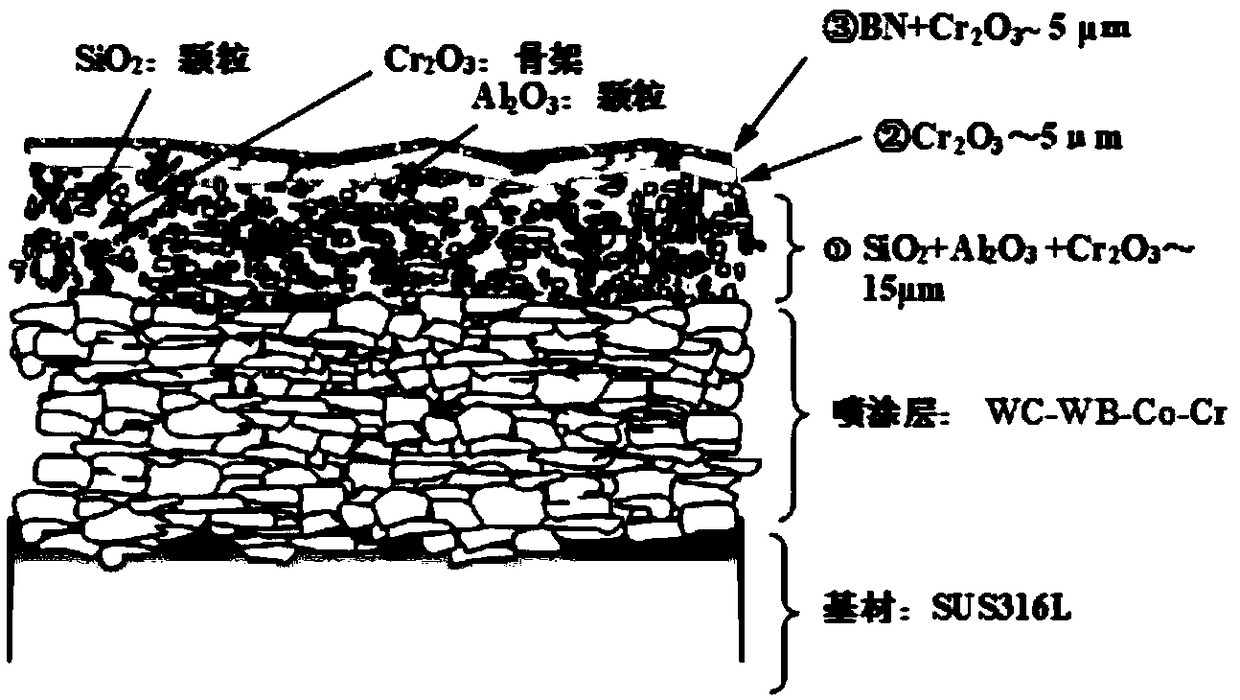

[0030] 2. Supersonic spraying, turn on the equipment for spraying

[0031] (1) spray gun: optional spray gun;

[0032] (2) Spraying material: WC-WB-Co-Cr 60 / 30 / 5 / 5, the composition is C: 3.5~4.5%, B: 1~2%, Co: 4~6%, Cr: 4~6% , the rest is W; powder particle size range 10 ~ 45μm.

[0033] (3) Oxygen consumption: 800 standard liters / ...

Embodiment 2

[0044] This embodiment includes the following steps:

[0045] 1. Pretreatment before spraying of sinking roller

[0046] (1) Derust and decontaminate the surface of the sinking roller until the surface of the roller is smooth;

[0047] (2) For the sandblasting treatment on the surface of the sunken roller after the above step (1) treatment, use a direct shot sandblasting machine, carry out sandblasting and roughening treatment on the surface of the sunken roller by the mechanical hand-held sandblasting gun in the sandblasting room, and use 20 ~60 mesh white corundum sand, the surface roughness of the roller reaches Ra3~8 after sandblasting.

[0048] 2. Supersonic spraying, turn on the equipment for spraying

[0049] (1) spray gun: optional spray gun;

[0050] (2) Spraying material: WC-WB-Co-Cr 60 / 30 / 5 / 5, the composition is C: 3.5~4.5%, B: 1~2%, Co: 4~6%, Cr: 4~6% , the rest is W; powder particle size range 10 ~ 45μm.

[0051] (3) Oxygen consumption: 830 standard liters / ...

Embodiment 3

[0063] This embodiment includes the following steps:

[0064] 1. Pretreatment before spraying of sinking roller

[0065] (1) Derust and decontaminate the surface of the sinking roller until the surface of the roller is smooth;

[0066] (2) For the sandblasting treatment on the surface of the sunken roller after the above step (1) treatment, use a direct shot sandblasting machine, carry out sandblasting and roughening treatment on the surface of the sunken roller by the mechanical hand-held sandblasting gun in the sandblasting room, and use 20 ~60 mesh white corundum sand, the surface roughness of the roller reaches Ra3~8 after sandblasting.

[0067] 2. Supersonic spraying, turn on the equipment for spraying

[0068] (1) spray gun: optional spray gun;

[0069] (2) Spraying material: WC-WB-Co-Cr 60 / 30 / 5 / 5, the composition is C: 3.5~4.5%, B: 1~2%, Co: 4~6%, Cr: 4~6% , the rest is W; powder particle size range 10 ~ 45μm.

[0070] (3) Oxygen consumption: 860 standard liters / ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com