Pearl gentian grouper puffed feed based on high value protein source of tuna waste

A technology of pearl gentian and extruded feed, applied in the direction of animal feed, animal feed, and animal feed molding or processing, can solve the problem of high breeding cost, and achieve the effect of expanding the scope of application, reducing dependence and reducing breeding cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

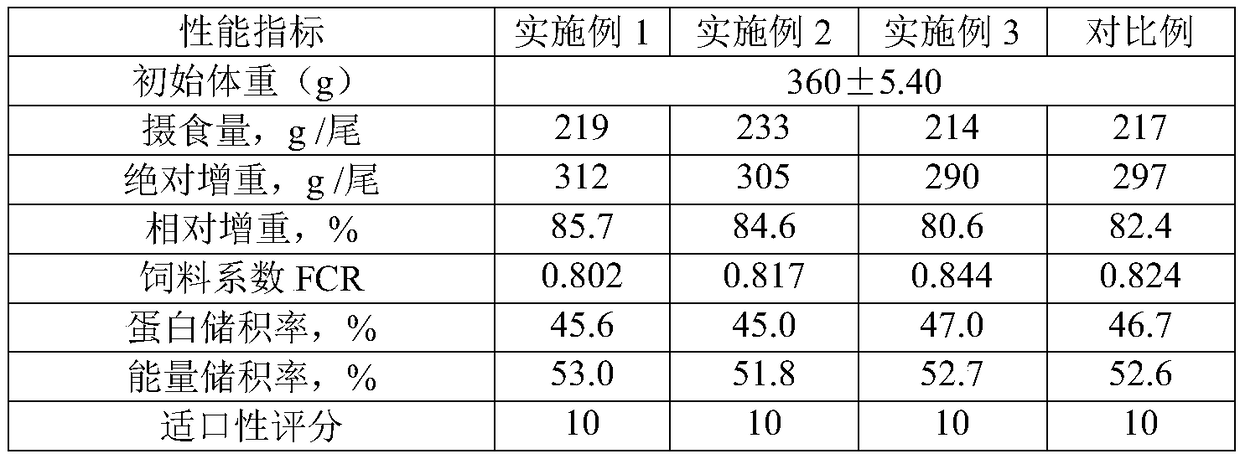

Examples

Embodiment 1

[0033] (1) Crushing: all ingredients are superfinely crushed and passed through 30 sieve;

[0034] (2) One mix: Weigh 2kg of phospholipid powder, 3kg of multi-dimensional polyminerals, 0.15kg of choline chloride, 0.01kg of yttrium oxide, 1kg of calcium dihydrogen phosphate, 0.1kg of L-lysine and 0.1kg of DL-methionine. The mixer stirs evenly, the stirring speed is 20r / min, to obtain a mixed mixture, and it is ready for use;

[0035] (3) Second mix: Weigh 11kg of soy milk treasure, 6.34kg corn gluten meal, 40.5kg Peruvian fish meal (day), 4kg gluten, 5kg soybean meal, 13.5kg flour into the mixer for preliminary mixing, and mix with the first mix Mix again to obtain a two-mix mixture; (4) Three-mix: use spray addition to dilute 2 kg of tuna scraps high-value protein source with water and spray uniformly into the second-mix mixture obtained in step (3) to obtain a three-mix mixture;

[0036] (5) Maturation: Let the three-mix mixture stand for several hours or overnight. After the dry m...

Embodiment 2

[0042] (1) Crushing: All ingredients are superfinely crushed and passed through 40 sieves;

[0043] (2) One mix: Weigh 2kg of phospholipid powder, 3kg of multi-dimensional polyminerals, 0.15kg of choline chloride, 0.01kg of yttrium oxide, 1kg of calcium dihydrogen phosphate, 0.1kg of L-lysine and 0.1kg of DL-methionine. The mixer stirs evenly, and the stirring speed is 30r / min, to obtain a mixed mixture, ready for use;

[0044] (3) Second mix: Weigh 17kg of soy milk treasure, 12.84kg of corn gluten meal, 14.8kg of Peruvian fish meal (day), 4kg of gluten, 5kg of soybean meal, and 11kg of flour into the mixer for preliminary mixing, and then mix with the first mix again Mix to obtain a two-mix mixture;

[0045] (4) Three-mix: 16kg of tuna scraps of high-value protein source is diluted with water by spray addition, and then uniformly sprayed in the second-mix mixture obtained in step (3) to obtain a three-mix mixture;

[0046] (5) Maturation: Let the three-mix mixture stand for several ...

Embodiment 3

[0052] (1) Crushing: all ingredients are superfinely crushed and passed through 50 sieves;

[0053] (2) One mix: Weigh 2kg of phospholipid powder, 3kg of multi-dimensional polyminerals, 0.15kg of choline chloride, 0.01kg of yttrium oxide, 1kg of calcium dihydrogen phosphate, 0.1kg of L-lysine and 0.1kg of DL-methionine. The mixer stirs evenly, and the stirring speed is 25r / min, to obtain a mixed mixture, ready for use;

[0054] (3) Second mix: Weigh 16kg of soy milk treasure, 11.14kg of corn gluten meal, 23.5kg of Peruvian fish meal (day), 4kg of gluten, 5kg of soybean meal, and 10kg of flour into the mixer for preliminary mixing, and then mix with the first mix again Mix to obtain a two-mix mixture;

[0055] (4) Three-mix: use spray addition to dilute 12 kg of tuna scraps high-value protein source with water, and then uniformly spray it into the second-mix mixture obtained in step (3) to obtain a three-mix mixture;

[0056] (5) Maturation: Let the three-mix mixture stand for several...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com