Natto noodles and production method thereof

A production method and noodle technology, which are applied in the field of noodle product processing, can solve the problems of restricting the way of eating natto, difficult to ensure the active substance of natto, natto with odor, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

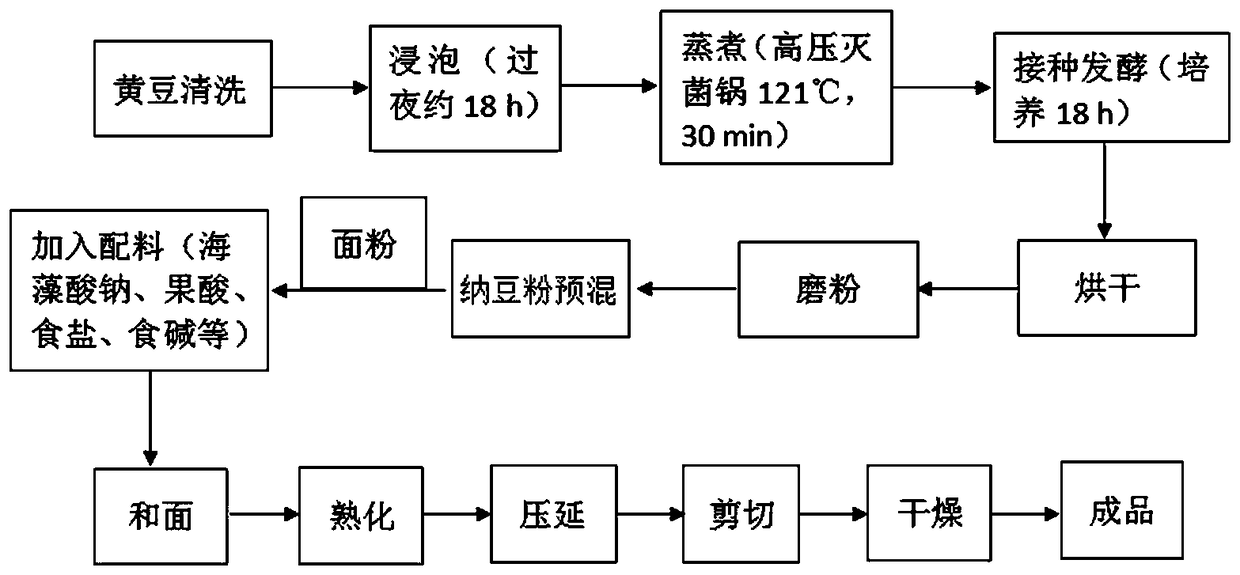

Method used

Image

Examples

Embodiment 1

[0027] The invention provides a kind of natto vermicelli, by weight: 50 parts of high-gluten wheat flour, 10 parts of natto powder, 30 parts of water, 0.15 parts of alkali, 1 part of sodium alginate, 0.4 parts of salt.

[0028] Specific steps:

[0029] S1. Soak soybeans in water overnight for 18 h, place them in an autoclave at 121 °C for 30 min, then cool to 40 °C, inoculate and ferment, ferment in a constant temperature incubator at 37 °C for 18 h, and vacuum freeze-dry for 10- After 15 hours, it was dried and crushed into natto powder for later use.

[0030] S2. Kneading dough: Weighing flour, natto powder, salt, water, sodium alginate, food alkali and premixed natto powder in parts by weight to obtain uniform dough.

[0031] S3. Ripening: Mature the dough for 30-40 minutes at a temperature of 45°C-55°C and a relative humidity of 50%-60%, and then press the matured dough into a noodle with a thickness of 2-4mm through multiple rollers Sheets, let the noodles stand at a t...

Embodiment 2

[0037] The invention provides a kind of natto vermicelli, in parts by weight: 55 parts of high-gluten wheat flour, 6 parts of natto powder, 22 parts of water, 0.1 part of caustic soda, 1.2 parts of sodium alginate, 0.8 parts of Salt, 13 parts of egg white.

[0038] Compared with the first embodiment, in the second embodiment, the weight parts of the raw materials are optimized, the food alkali is divided into two parts, and at the same time, 13 parts of egg whites are added. When kneading noodles, first weigh natto powder and alkali respectively by weight, and premix natto powder with alkali successively to obtain premixed powder; then weigh flour, egg white, salt, water by weight respectively , sodium alginate, food alkali and premixed natto powder are kneaded to obtain a uniform dough.

Embodiment 3

[0040] The invention provides a natto vermicelli, which comprises, in parts by weight: 60 parts of high-gluten wheat flour, 4 parts of natto flour, 24 parts of water, 0.1 part of food alkali, 1.2 parts of sodium alginate, 0.63 parts of table salt, and 10 parts of egg white , 0.07 parts of fruit acid.

[0041] Compared with the second embodiment, in the third embodiment, the weight portion of raw materials is further optimized, and fruit acid is added, and fruit acid can be a kind of in grape acid, malic acid, citrus acid, lactic acid and glycolic acid or several. Malic acid was used in this example. When kneading noodles, first take natto powder, food alkali and fruit acid by weight respectively, premix natto powder with food alkali successively, after mixing evenly, add malic acid for premixing, obtain premixed powder; The flour, egg white, salt, water, sodium alginate, and alkali are weighed and kneaded with the premixed natto powder in parts by weight to obtain a uniform ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com