Extraction system and method for metabolite in microalgae cells

A technology for microalgae cells and metabolites, applied in solvent extraction, separation methods, solid solvent extraction, etc., can solve the problems of environmental governance burden, low utilization rate of microalgae, inability to realize microalgae circulation and re-extraction, and achieve Equal stroke area distribution, shortening the effect of extraction and separation cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

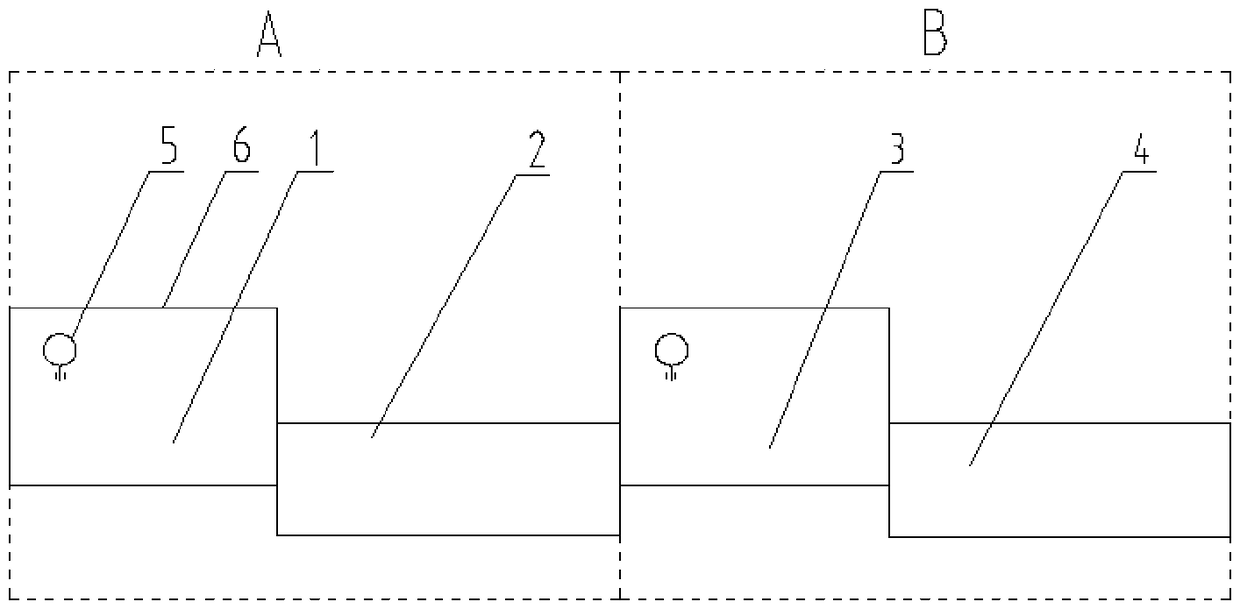

[0059] Such as figure 1 As shown, a secondary extraction system for microalgae cells, the extraction system includes: a first-stage extraction and separation unit A, and a second-stage extraction and separation unit B.

[0060] The first-stage extraction and separation unit A is composed of a first-stage low-permeability extraction chamber 1 and a first-stage vacuum separation chamber 2 .

[0061] The second-stage extraction and separation unit B is composed of a secondary hypotonic liquid extraction chamber 3 and a secondary vacuum separation chamber 4 .

[0062] Both the primary hypotonic fluid extraction chamber 1 and the secondary hypotonic fluid extraction chamber 3 are composed of a hypotonic fluid jet tube 5 and a protective cover 6 .

[0063] After the microalgal cells first enter the primary hypotonic fluid extraction chamber 1 in the primary extraction and separation unit A, the hypotonic fluid is sprayed through the hypotonic fluid jet tube 5 for extraction. Under ...

Embodiment 2

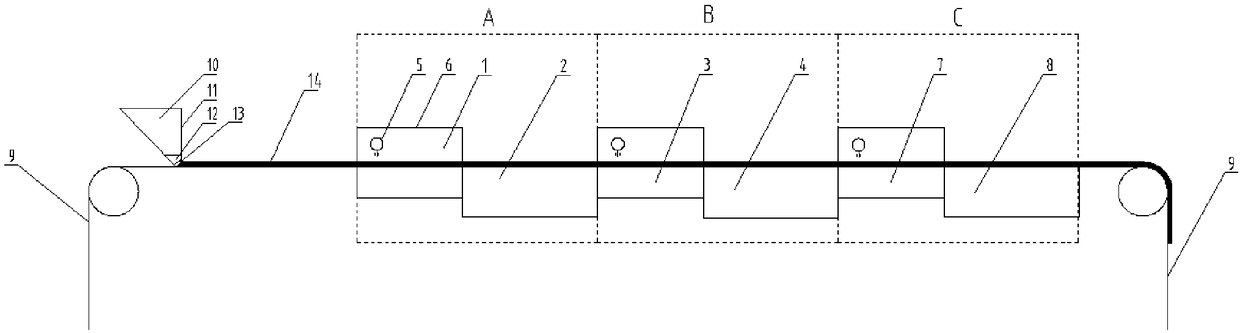

[0066]This embodiment provides a three-stage extraction system with better extraction and separation effects. To achieve this purpose, first of all, this embodiment designs a porous filter belt with both transportation and filtration functions in the extraction system, which can simultaneously realize microalgae Transport and separation of cells and extracts. Secondly, by setting the transmission rate of the porous filter belt to match the low-osmotic extraction and vacuum separation process, the multi-stage extraction and separation of microalgae cells can be carried out simultaneously, thereby greatly shortening the extraction and separation cycle of the metabolites to be extracted. Finally, in this embodiment, an algae mud homogenizing device is designed in the extraction system, which can realize equal thickness, uniformity, and equal travel area distribution of microalgae cells, and avoid the influence of the void covered by algae mud on the subsequent vacuum separation. ...

Embodiment 3

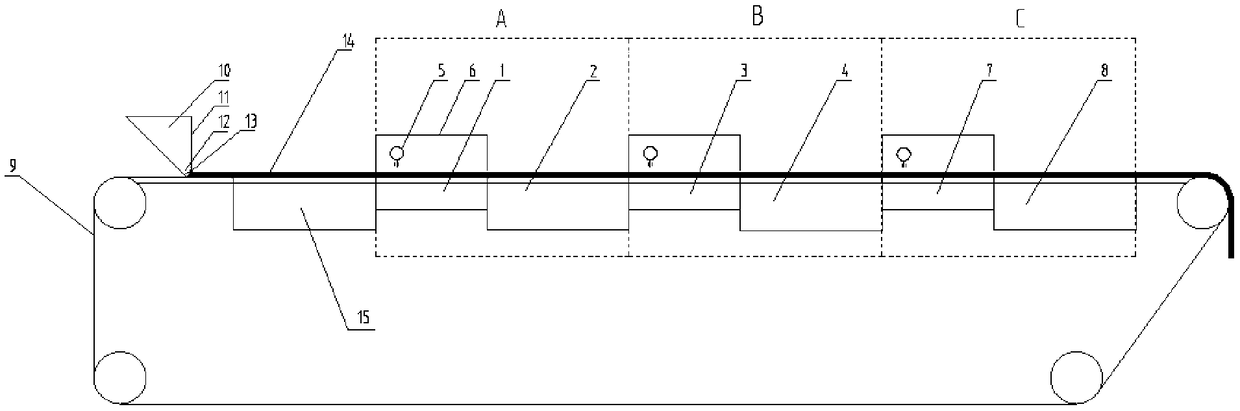

[0079] This embodiment provides another three-stage extraction system with better extraction and separation effects. To achieve this purpose, this embodiment designs a primary vacuum separation chamber in the extraction system, and the primary vacuum separation chamber is set at the first stage of extraction. Before the separation unit, the water or water-soluble mixture in the microalgae cells is pre-extracted before the microalgae cells enter the first-stage extraction separation unit, because after harvesting, the algae mud formed by the microalgae cells still contains more If the water is not removed, firstly, it will affect the concentration of hypotonic fluid in the subsequent hypotonic extraction treatment; secondly, it will dilute the concentration of the metabolites to be extracted in the extraction solution, increasing the difficulty of subsequent purification, increasing the purification time, Cost, affecting product quality, etc., are not conducive to the industrial...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com