Method for purifying and recovering aged phosphoric acid polishing solution

A technology of polishing liquid and phosphoric acid, which is applied in chemical instruments and methods, multi-stage water/sewage treatment, multi-stage water treatment, etc., can solve the problems of poor filterability, inability to achieve recycling of phosphoric acid polishing liquid, failure to achieve recovery, etc. , to achieve the effect of wide application prospects

Active Publication Date: 2021-07-30

昆山尚道源环境技术有限公司 +2

View PDF7 Cites 1 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, the filterability of this kind of sediment is very poor, and a large amount of phosphoric acid will be trapped in it, so that phosphoric acid and phosphate will be lost together, and the recovery effect cannot be achieved.

Therefore, it is impossible to use a single technical means to efficiently recycle the aged phosphoric acid polishing solution.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

[0016] In view of the deficiencies in the prior art, the inventor of this case was able to propose the technical solution of the present invention after long-term research and extensive practice. The technical solution, its implementation process and principle will be further explained as follows.

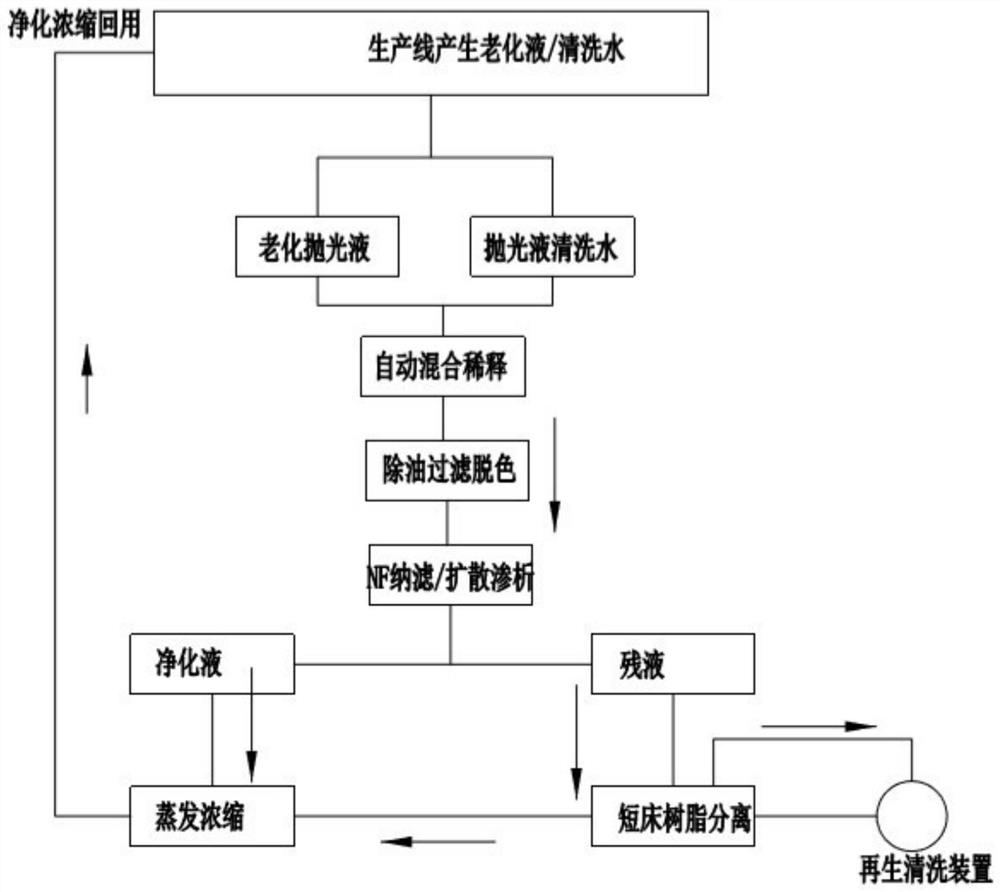

[0017] Embodiments of the present invention provide a method for purifying and recovering aged phosphoric acid polishing liquid, comprising:

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

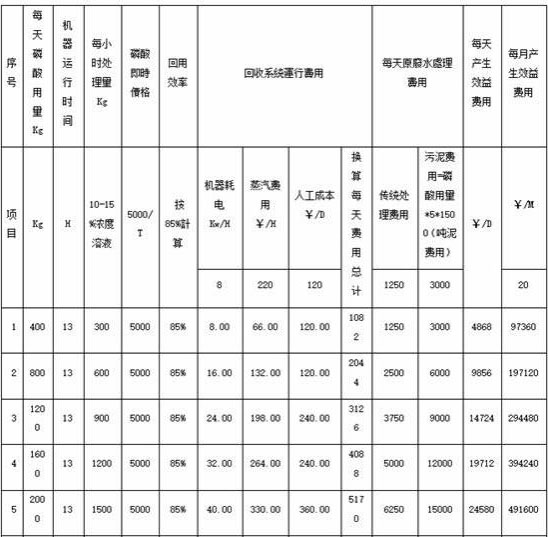

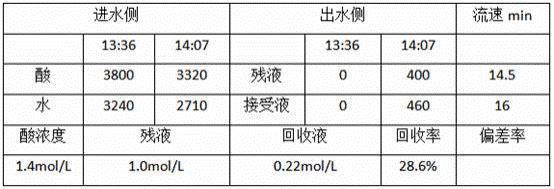

The invention discloses a method for purifying and recovering aged phosphoric acid polishing solution, which comprises: a first step of detecting the volume ratio of phosphoric acid and sulfuric acid in the polishing solution, and a second step of purifying the polishing solution; the second step comprises: If the volume ratio of phosphoric acid and sulfuric acid in the polishing solution is greater than 4:1, the polishing solution is purified by combining acid retardation and short bed composite resin technology; if the volume ratio of phosphoric acid and sulfuric acid in the polishing solution is 2:1~3 : 1, the polishing solution is purified by combining nanofiltration and acid retardation; if the volume ratio of phosphoric acid and sulfuric acid in the polishing solution is 1:1 to 2:1, the combination of diffusion dialysis and short-bed composite resin technology Purify the polishing solution in a manner. The method for purifying and recovering the aging phosphoric acid polishing solution provided by the present invention can achieve a recovery rate of 90-95% for the acid solution, and a removal rate of 90-98% for aluminum and other metal impurities, which can not only realize the green treatment of the waste liquid, but also It can realize the recycling of phosphoric acid, sulfuric acid and non-ferrous metal materials.

Description

technical field [0001] The invention particularly relates to a method for purifying and recovering aged phosphoric acid polishing solution, which belongs to the technical field of waste water waste liquid recycling and treatment. Background technique [0002] The harm of waste acid to groundwater is far greater than that of general chemical wastewater. When it seeps into the ground, it also reacts with carbonates, sulfites, and sulfides in rocks and soil to generate sulfur dioxide, hydrogen sulfide, and other harmful gases. into the air, polluting the atmosphere. In industries that generate a large amount of waste acid, such as non-ferrous metals and titanium dioxide industries, the discharged waste acid contains a large amount of heavy metals, which dissolve into rivers or underground, causing serious pollution to rivers or groundwater. Using these polluted water for irrigation, and caused serious pollution to the soil. The waste acid discharged from the organic chemical ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C02F9/04C02F9/10

CPCC02F1/001C02F1/048C02F1/283C02F1/42C02F1/44C02F1/442C02F9/00C02F2301/08C02F2303/16

Inventor 卢征春苏泱洲

Owner 昆山尚道源环境技术有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com