A method for improving the installation firmness of building wall panels

A firm, building wall technology, applied in the processing of building materials, construction, building components, etc., can solve the problems of poor thermal insulation, inability to sound insulation, weakening impact, etc., to achieve good control, prevent the spread of fire, and isolate the fire. the effect of spreading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

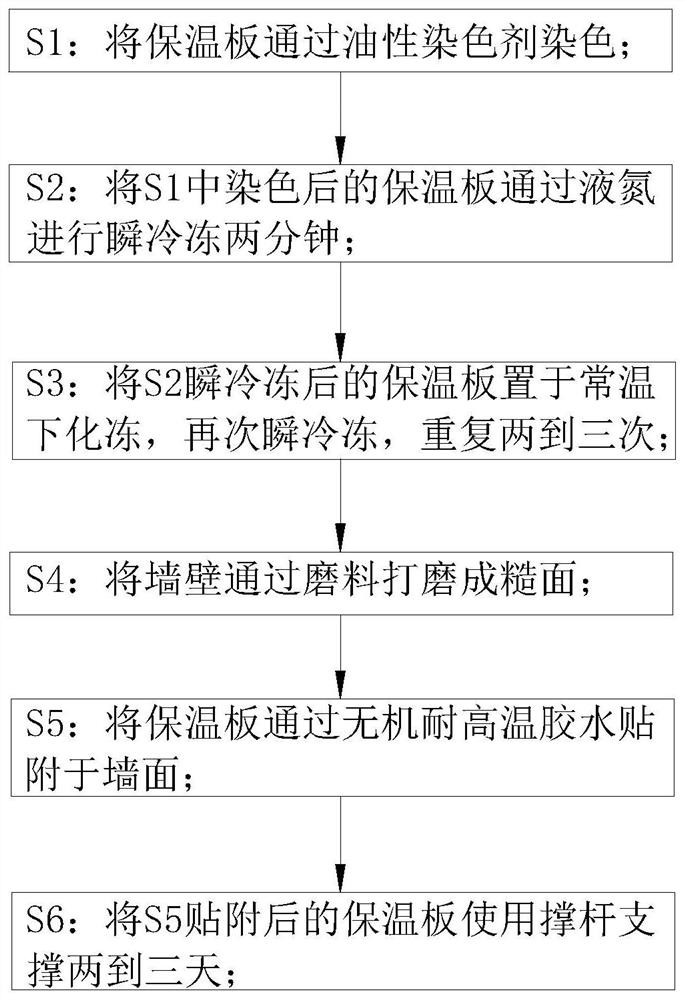

Method used

Image

Examples

Embodiment approach

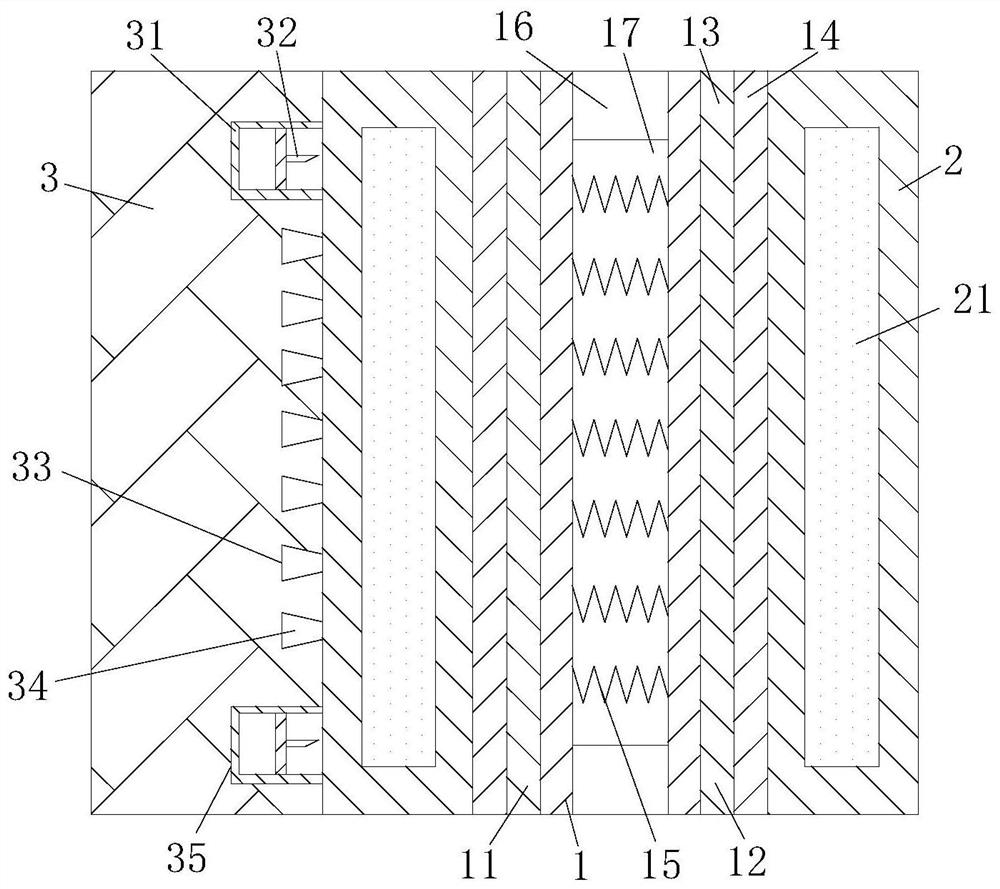

[0040] As an embodiment of the present invention, the fire-proof layer 2 is provided with a water bag 21, which is filled with water. When working, the water in the water bag 21 can cool down the room well, thereby preventing The effect of fire spread.

[0041] As an embodiment of the present invention, the upper and lower ends of the sound insulation layer 3 are provided with two grooves 35, and a mercury cylinder 31 is arranged in the groove 35; the mercury cylinder 31 is horizontally arranged and the extension of the mercury cylinder 31 The outlet end is set toward the fireproof layer 2, and the movable rod 32 is conical; the high temperature causes the mercury in the mercury cylinder 31 to expand and puncture the water bag 21, so that the water in the water bag 21 flows into the fireproof layer 2 and mixes with the seabed mud. The fire plays a very good control role and isolates the spread of the fire.

[0042] As an embodiment of the present invention, the fire-proof lay...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com