Kinetic inhibition oil-water emulsion responsive to hydrates and preparation method and application of emulsion

A kinetic inhibitor and kinetic technology, which is applied in mechanical equipment, gas/liquid distribution and storage, pipeline systems, etc., can solve the problem of inability to effectively prevent growth, aggregation and blockage of pipelines, decreased inhibitory effect of hydrate kinetic inhibitors, Concentration drop and other problems, to achieve the effect of ensuring performance, avoiding long-term contact, and stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

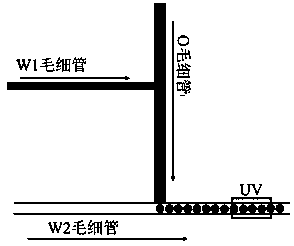

[0036] The invention adopts a microfluidic preparation method to prepare W / O / W type inhibitor emulsion. ① Dissolve the inhibitor in 10 wt% ethylene glycol aqueous solution, based on the mixed solution, the inhibitor concentration is 50 wt%; after fully dissolved, add 5.0 wt% polyvinyl alcohol as an active agent, and add a small amount of dye As a mark to track the cracking of the inhibited emulsion; ② Slowly inject the prepared inner layer inhibitor solution through a 300 μm capillary tube at a rate of 1 mL / h containing 99.0 wt% 2-phenoxyethyl acrylate and In the pipeline of the 1.0wt% photoinitiator mixed solution (the inner diameter of the pipeline is 350 μm, and the flow rate is 1.5 mL / h), a water-in-oil structure is naturally formed according to the polarity difference of the two solutions; ③ After that, the formed water-in-oil structure The structure was injected into a pipe (inner diameter 380 μm, flow rate 4.5 mL / h) containing 5.0 wt% polyvinyl alcohol solution to form ...

Embodiment 2

[0040] The hydrate inhibitor evaluation test system is a visual high pressure coil tube device. The device has a high-pressure stainless steel wheel tube reactor, temperature and pressure sensors, temperature control system, vacuum and data acquisition system and pipeline endoscope, which can reliably evaluate the performance of the inhibitor. Using this device can obtain evaluation indicators of the nucleation stage such as durable subcooling and induction time of the system, as well as hydrate blockage, etc., so as to comprehensively evaluate hydrate inhibitors (its structure is as shown in Chinese patent CN201410431032.7 record in). The results are scientific and reliable, with excellent reproducibility and evaluation capabilities. All the following implementation cases are tested with this device, and the induction time method is used to test the inhibition performance of the inhibitor on the hydrate phenomenon.

[0041] The present invention uses a high-pressure stirred...

Embodiment 3

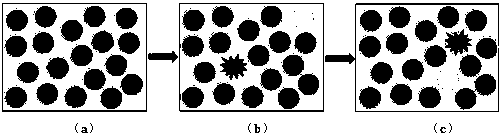

[0044] The invention uses a high-pressure stirred tank with a visible window to test the release process and performance of inhibiting the oil-water emulsion. After cleaning the reactor, the temperature of the reactor was stabilized at 25.0 o At C, add 237.5mL deionized and 12.5g suppressed oil-water emulsion to the reactor, and fill it with 11.6MPa methane gas. After the gas is dissolved and balanced, from 25 o C starts to cool down, with 1 o The rate of C / h is carried out, and the induction time of the first appearance of hydrate crystal nuclei, the situation of inhibiting the release of high-concentration inhibitors from the emulsion in the visible window, and the growth rate of hydrate crystal nuclei are recorded. Figure 4 The test results show that from 25 o C began to cool down to the end of the test, the system first appeared hydrate crystal nuclei, the growth rate of crystal nuclei, and the effect of inhibiting the release of high-concentration inhibitors from the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com