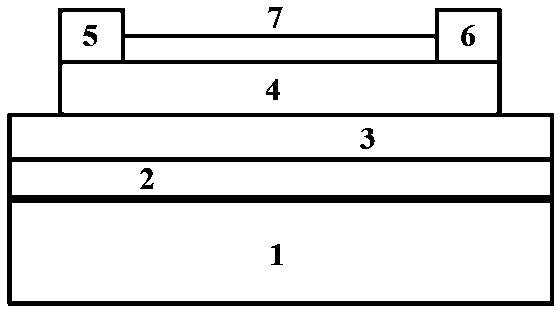

An n-type amorphous oxide semiconductor thin film transistor with flexible substrate and a preparation method thereof

A technology of amorphous oxide and thin-film transistors, which is applied in semiconductor/solid-state device manufacturing, transistors, semiconductor devices, etc., can solve the problems of high production costs, low geological reserves, unfavorable sustainable development, etc., and achieve sustainable development The effect of development, interface structure matching, and device cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

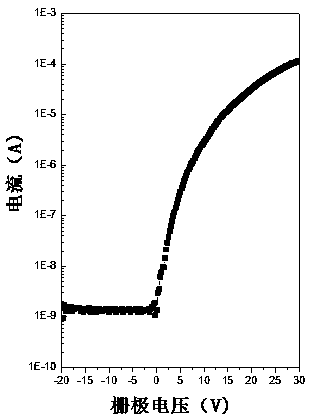

Examples

Embodiment 1

[0034] 1) Put the weighed ZnO, Al 2 o 3 , SnO 2 Add the powder into a ball mill jar with agate beads, add alcohol as a medium to mill on a ball mill, filter the milled slurry and place it in a drying oven for drying, and grind and filter the dried powder obtained after drying in a mortar. A 3-inch ZnAlSnO ceramic target was prepared by hot pressing and sintering.

[0035] 2) Use polyethylene naphthalate (PEN) as the organic flexible substrate, and ultrasonically clean it for 40 minutes in the order of acetone, ethanol, deionized water, and ethanol, and fix the cleaned substrate to the grid mask .

[0036] 3) A layer of AZO thin film was deposited on the organic flexible substrate by magnetron sputtering method with AZO ceramic sheet as the target material. The deposition conditions were as follows: the distance between the substrate and the target was 100 mm, and the growth chamber was pumped to vacuum at 1.0 x 10 -3 Above mTorr, the growth chamber is fed with Ar and O ...

Embodiment 2

[0045] 1) Put the weighed ZnO, Al 2 o 3 , SnO 2 Add the powder into a ball mill jar with agate beads, add alcohol as a medium to mill on a ball mill, filter the milled slurry and place it in a drying oven for drying, and grind and filter the dried powder obtained after drying in a mortar. A 3-inch ZnAlSnO ceramic target was prepared by hot pressing and sintering.

[0046] 2) Use polyethylene terephthalate (PET) as the organic flexible substrate, and ultrasonically clean it for 40 minutes in the order of acetone, ethanol, deionized water, and ethanol, and fix the cleaned substrate to the gate mask plate.

[0047] 3) A layer of AZO thin film was deposited on the organic flexible substrate by magnetron sputtering method with AZO ceramic sheet as the target material. The deposition conditions were as follows: the distance between the substrate and the target was 100 mm, and the growth chamber was pumped to vacuum at 1.0 x 10 -3 Above mTorr, the growth chamber is fed with Ar ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com