Preparation method of quantum dot sensitized solar cell processed by full-water-solubility solvent

A water-soluble solvent, quantum dot sensitization technology, applied in the direction of photosensitive equipment, etc., can solve the problems of affecting the photoelectric conversion efficiency of the battery, volatile, unfavorable transmission, etc., to achieve the effect of improving the photoelectric conversion efficiency, easy regulation, and easy perfusion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

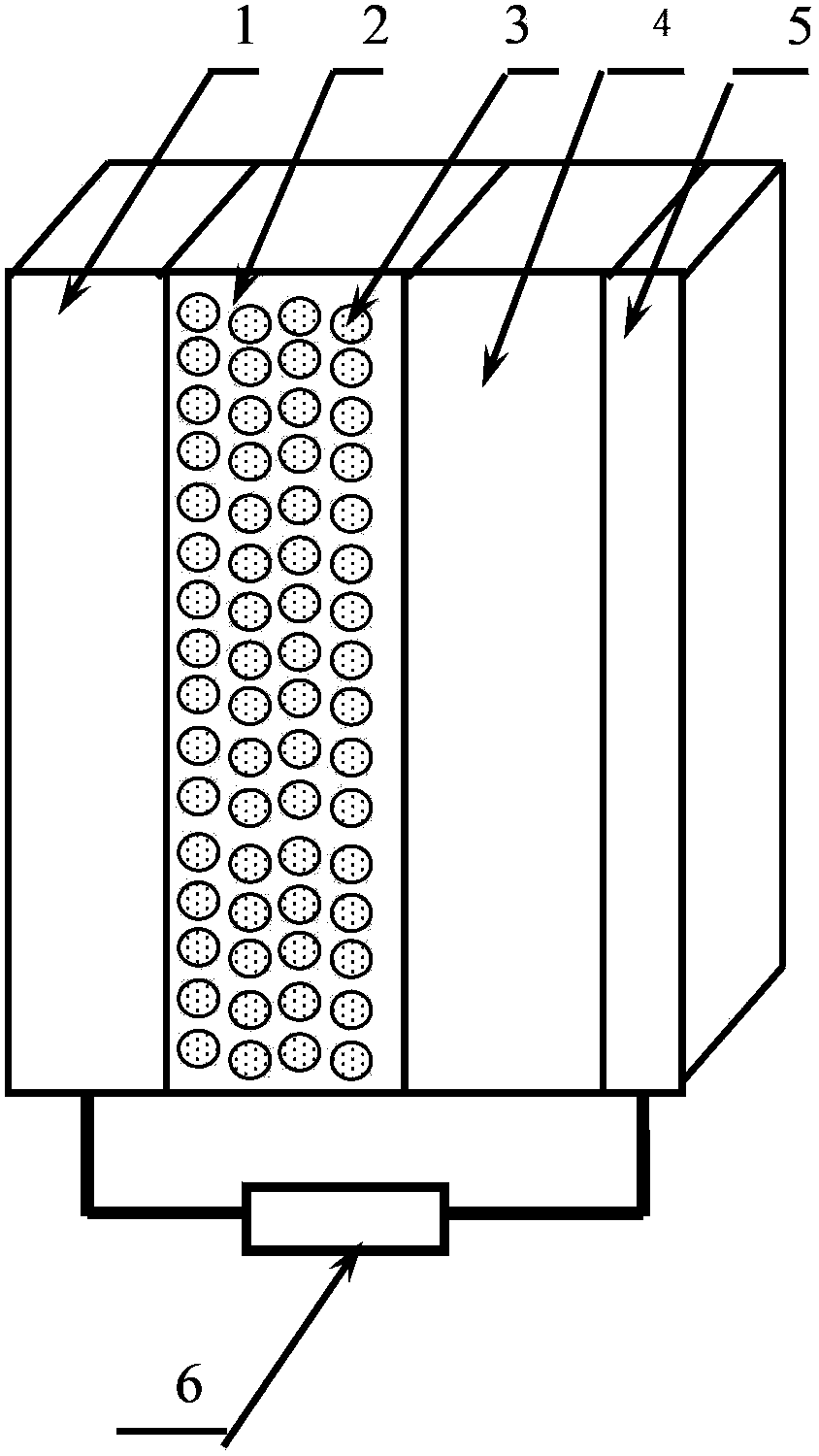

[0027] 1. With 30μl of Ti(OPr) 4 Disperse in 10ml of ethanol, prepare the precursor solution of titanium, and spin-coat on the surface of the conductive substrate FTO conductive glass 1 cleaned by ultrasonic, and then P25TiO 2 The powder was prepared into TiO with 100 μl of Triton X-100, 200 μl of acetylacetone, and 10 g of deionized water 2 Colloidal solution, after mixing uniformly by magnetic stirring and ultrasonic oscillation, the TiO 2 The colloidal solution is spin-coated on the surface of the conductive substrate FTO conductive glass 1, and then dried in an oven at 50°C; after drying, spin-coat TiO 2 Colloidal solution, prepared into oxide TiO after many repetitions 2 Porous membrane 2, and then put it into a muffle furnace to 450 ° C for 30 minutes to make oxide TiO 2 Porous membrane anode.

[0028] 2, the oxide TiO obtained through step 1 2 Porous membrane anode immersed in 0.1M CdSO 4 solution for 1 minute, take it out and rinse its surface with ethanol; then ...

Embodiment 2

[0034] 1. Mix the 350nm monodisperse polystyrene bead solution diluted to 0.1wt% with 0.003wt% surfactant Igepal CO-520 and ultrasonicate for 30 minutes, then place the conductive substrate FTO conductive glass cleaned by ultrasonic 1 Put the solution vertically, and then place it in a thermostat at 55°C until the solution evaporates completely. Add 0.12% (w / v) nitric acid to a 1.2% (w / v) ethanol solution of isopropyl titanate, put the conductive substrate FTO conductive glass 1 vertically into the solution and place it at room temperature for 5 minutes to grow on the surface A layer of titanium dioxide. Take out the FTO conductive glass 1 and dry it in air for 20 minutes. Mix 0.20mol / L ammonium hexafluorotitanate and 0.25mol / L boric acid aqueous solution at 51°C, adjust the pH to 2.9 with 1mol / L hydrochloric acid, immerse the FTO conductive glass 1 vertically in the solution for 30 minutes, then take it out and use deionized Wash with water, dry in the air at room temperatu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com