Microstrip series-fed linear array circularly polarized microstrip antenna

A technology of microstrip antenna and circular polarization, applied in the direction of antenna, antenna coupling, antenna components, etc., can solve the problems of complex feeding circuit, complicated processing process, inconvenient integration, etc., and achieve simple feeding system and radiation axis ratio Low, the effect of increasing the antenna gain

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

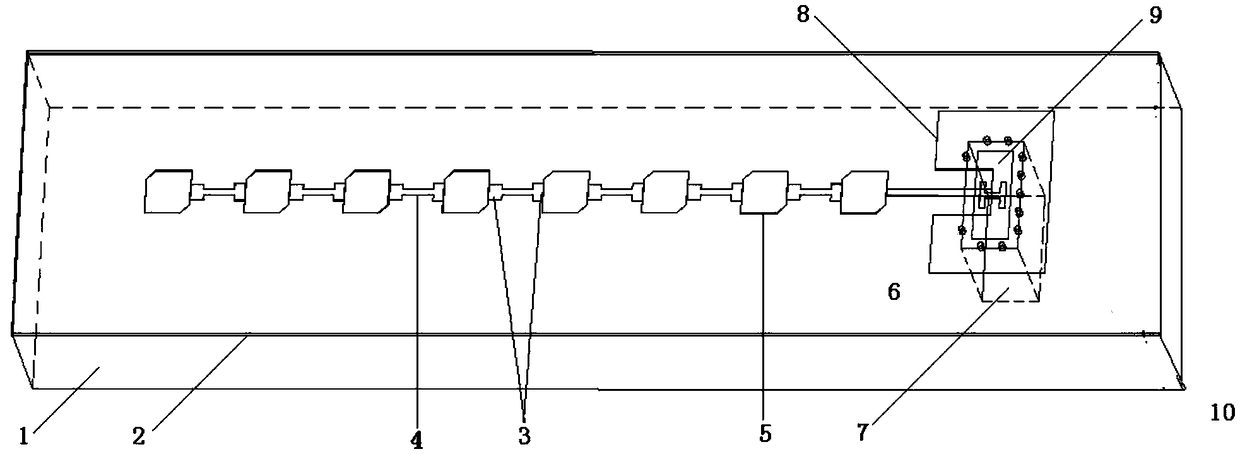

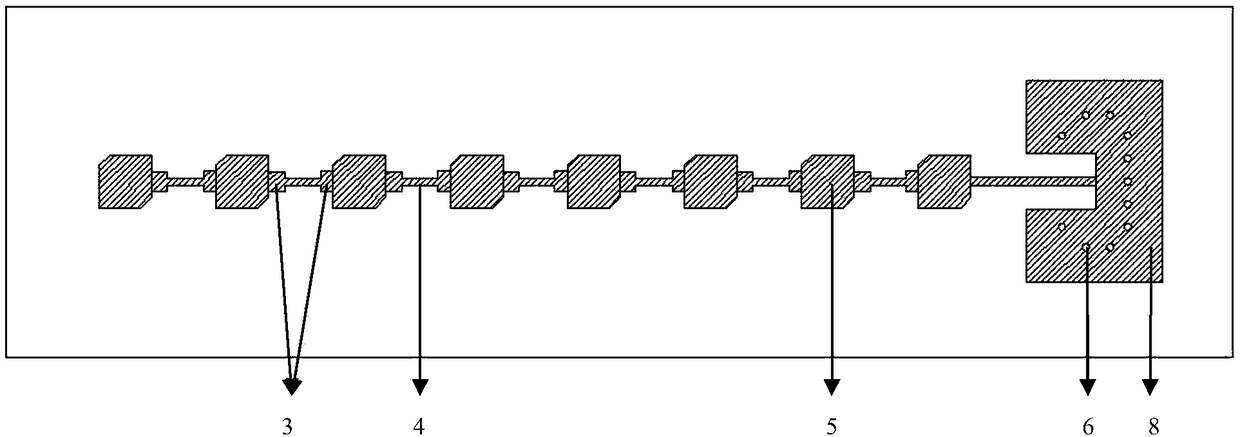

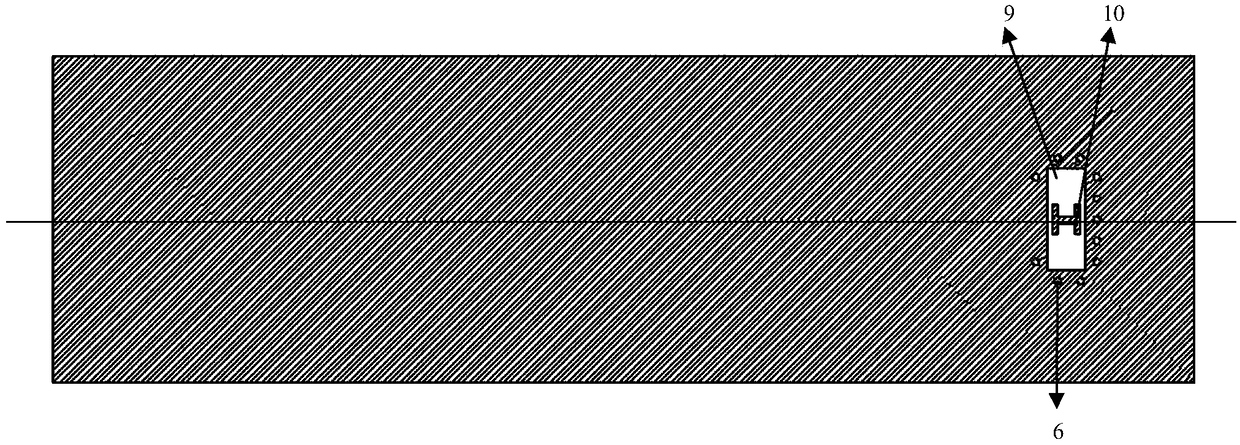

[0018] refer to Figure 1-3 . In the embodiment described below, the dielectric substrate 2 laminated on the metal plate 1 and the metal floor closely attached to the lower surface of the dielectric substrate 2 are included. The copper-clad sheet on the surface of the dielectric substrate 2 is etched into a microstrip metal radiation patch 5 connected in series with the microstrip series feeder 4 and a transition metal patch 8 with a rectangular groove connected to the end microstrip series feeder line. The metal patch 8, the microstrip metal radiation patch 5, and the microstrip serial feeder 4 are all on the upper surface of the dielectric substrate 2, and the lower surface layer of the dielectric substrate 2 is a thin metal sheet. On the surface metal floor under the dielectric substrate 2, a rectangular coupling slit 9 corresponding to the transition metal patch 8 and an H-shaped coupling patch 10 framed in the rectangular coupling slit 9 are etched, and the rectangular c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com