Nanofiber moisturizing facial mask with viscous hydroxyl functional group on surface as well as preparation method and application of nanofiber moisturizing facial mask

A hydroxyl functional group and nanofiber technology, which is applied in fiber treatment, fiber chemical characteristics, skin care preparations, etc., can solve the problems of skin allergies, lack of moisturizing function, increase cost, etc., and achieve the effect of improving skin condition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

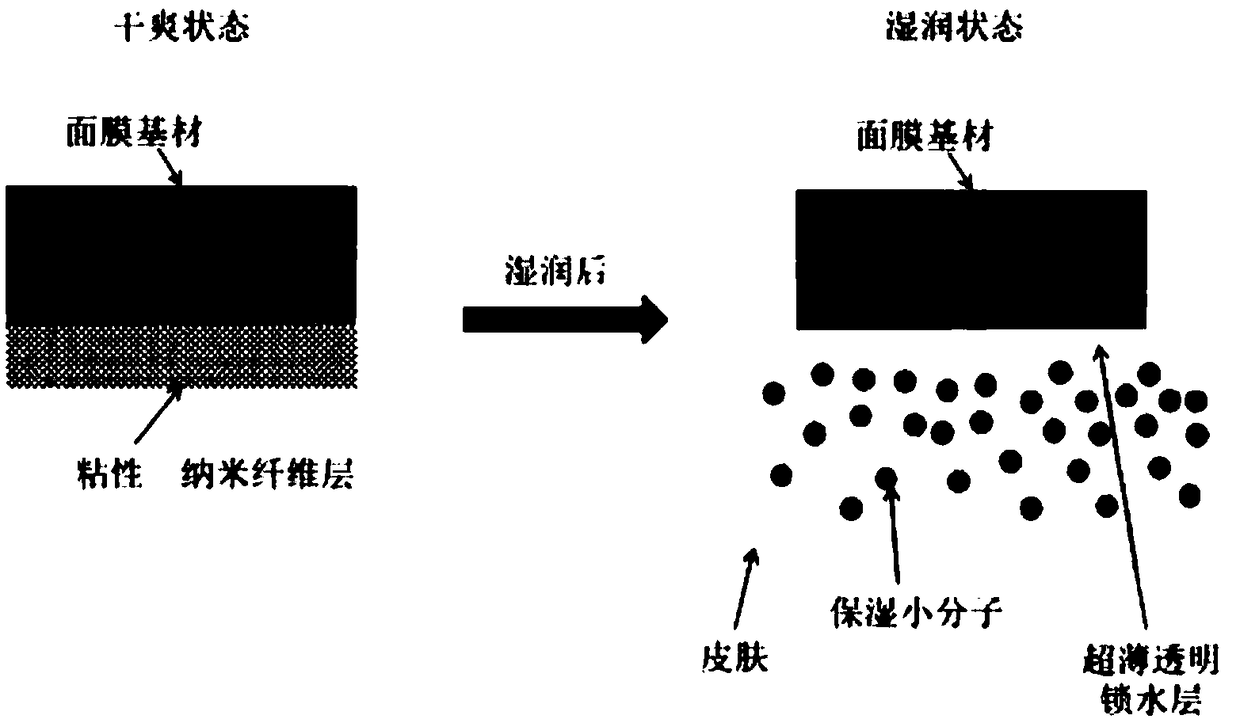

[0024] The invention provides a method for preparing a nanofiber moisturizing mask with viscous hydroxyl functional groups on the surface, comprising the following steps:

[0025] (1) mixing a solute comprising glycerin, hyaluronic acid, polyethylene oxide, urea, allantoin and sodium pyrrolidone carboxylate with a solvent to obtain a spinning solution;

[0026] (2) the spinning liquid electrospinning that described step (1) obtains is to the one side of mask base material, forms sticky nanofiber layer on described mask base material surface;

[0027] (3) The surface of the viscous nanofiber layer obtained in the step (2) is pasted with a protective layer to obtain a nanofiber moisturizing mask with viscous hydroxyl functional groups on the surface.

[0028] In the invention, the solute including glycerin, hyaluronic acid, polyethylene oxide, urea, allantoin and sodium pyrrolidone carboxylate is mixed with a solvent to obtain a spinning solution. In the present invention, the ...

Embodiment 1

[0051] Glycerin, hyaluronic acid, polyethylene oxide, urea, allantoin, sodium pyrrolidone carboxylate and a solvent are mixed to obtain a spinning solution, and the solute in the spinning solution includes the following components by weight fraction: glycerin 15%, Hyaluronic acid 30%, polyethylene oxide 15%, urea 15%, allantoin 10%, sodium pyrrolidone carboxylate 15%.

[0052] Spinning liquid is on mask substrate (spun-bonded non-woven fabric, and film resistance is 107Ω / sq, and gram weight is 10g / m 2 ) for electrospinning, the electrospinning voltage is 20kV, the electrospinning time is 0.5h, the distance between the spinneret and the mask substrate is 18cm, the moving speed of the mask substrate is 0.1m / min, and the injection speed At 1 mL / min, a viscous nanofiber layer of 50 μm was obtained. The resulting viscous nanofibrous layer was observed under a microscope, and the results were as follows figure 2 ,Depend on figure 2 It can be seen that the sticky nanofiber layer...

Embodiment 2

[0062] Glycerin, hyaluronic acid, polyethylene oxide, urea, allantoin, sodium pyrrolidone carboxylate and a solvent are mixed to obtain a spinning solution, and the solute in the spinning solution includes the following components by weight fraction: glycerin 15%, Hyaluronic acid 10%, polyethylene oxide 15%, urea 15%, allantoin 10%, sodium pyrrolidone carboxylate 15%, hydrolyzed collagen 20%.

[0063] Spinning liquid is on mask substrate (spun-bonded non-woven fabric, and film resistance is 100Ω / sq, and gram weight is 12g / m 2 ) carries out electrospinning on one side, the electrospinning voltage is 100kV, the time of electrospinning is 5, the distance between the spinneret and the mask base material is 10cm, the moving speed of the mask base material is 2.0m / min, and the injection speed is 0.1 mL / min to obtain a viscous nanofiber layer of 50 μm.

[0064] The sticky nanofiber layer is bonded to the pearl film to obtain a nanofiber moisturizing mask with sticky hydroxyl functio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

| Basis weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com