Micro reaction device and method for synthesizing ferroferric oxide nano-powder

A micro-reaction device, ferric oxide technology, applied in chemical instruments and methods, iron oxide/iron hydroxide, chemical/physical/physicochemical reactors, etc., to achieve narrow particle size distribution, avoid wall deposition and micropipes The effect of clogging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

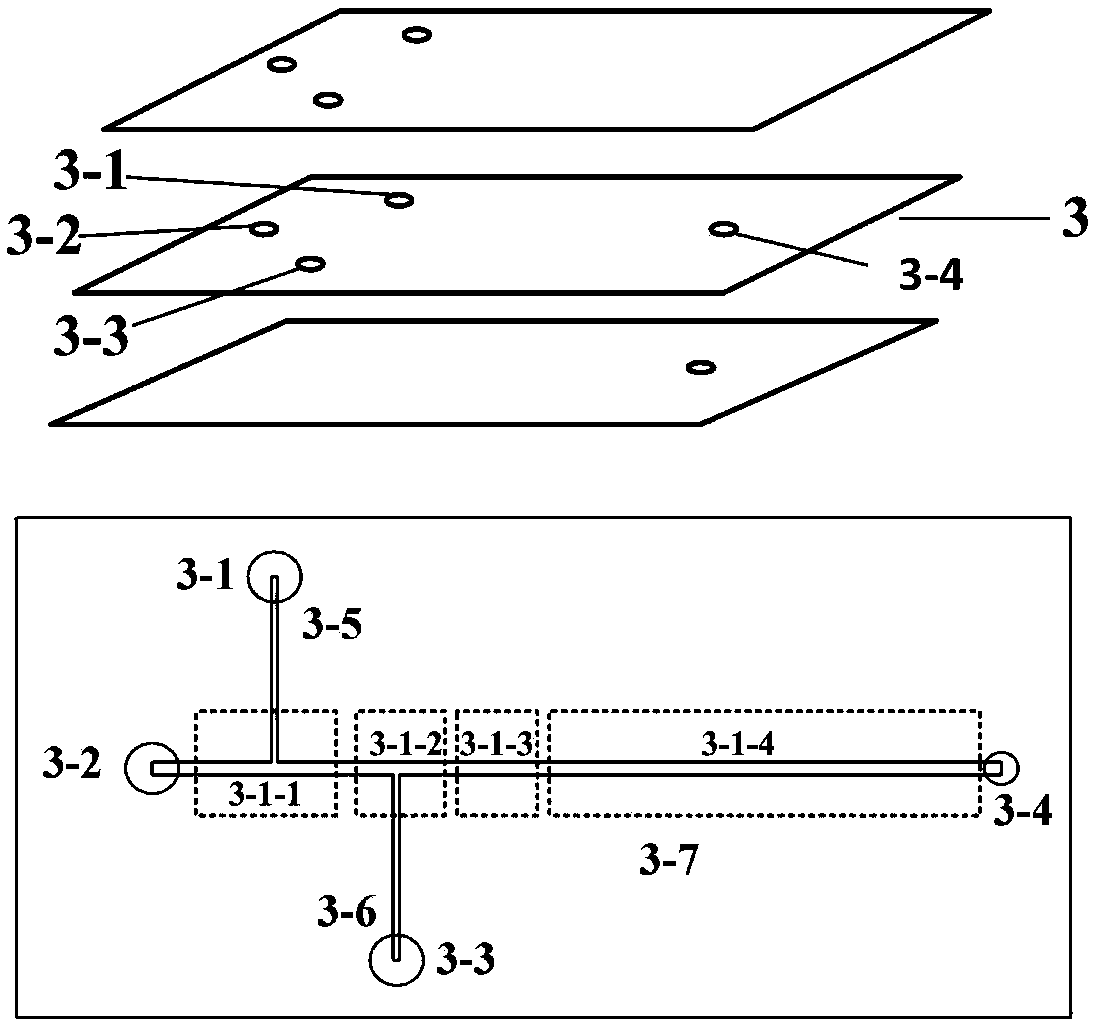

[0096] Embodiment 1 (taking microchannel reactor-1 as example, as Figure 9-10 shown)

[0097] (1) Dissolve 4.97 g span80 in 34.80 g hexadecane to prepare the carrier continuous phase. Dissolve 1.19 g of ferrous chloride and 3.24 g of ferric chloride in 50 ml of water to prepare a mixed solution of 0.12 mol / L ferrous chloride and 0.24 mol / L ferric chloride. Dissolve 3.84 g of sodium hydroxide in 50 ml of water to prepare a solution of 1.92 mol / L.

[0098] (2) Inject the hexadecane carrier continuous phase containing span80 into the micro-reaction main channel (3-7) of the carrier continuous phase of the microreactor at a flow rate of 40 µL / min through the micro-syringe pump-2, which can precisely control the flow rate; The alkaline solution is injected into the alkaline solution branch channel (3-5) at a flow rate of 20 µL / min through the micro-injection pump-1, which can precisely control the flow rate, to form a uniform size and stable dispersion in the stable dispersion c...

Embodiment 2

[0104] Embodiment 2 (taking microchannel reactor-3 as example, as Figure 9-10 shown, and Figure 9 Microchannel Reactor-1 in is replaced by Microchannel Reactor-3)

[0105] In this example, the hexadecane carrier continuous phase, alkaline solution, Fe 2+ / Fe 3+ The preparation of the mixed solution is consistent with that of Example 1.

[0106] (1) Inject the hexadecane carrier continuous phase containing span80 into the micro-reaction main channel (5-7) of the carrier continuous phase of the microreactor at a flow rate of 40 µL / min through the micro-syringe pump-2, which can precisely control the flow rate; The alkaline solution is injected into the branch channel (5-5) of the alkaline solution at a flow rate of 20 µL / min through the micro-injection pump-1, which can precisely control the flow rate, to form a uniform size and stable dispersion in the stable dispersion channel cavity (5-1-1). droplet, after stabilization, the Fe 2+ / Fe 3+ The mixed solution is injected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com