Method for preparing Ni-MOF adsorbing material by ultrasonic assisted solvent-thermal method and application of Ni-MOF adsorbing material

An auxiliary solvent and adsorption material technology, which is applied in the field of preparation of heavy metal ion treatment agents, can solve the problems of limiting the application of MOF materials and poor water quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] A method for preparing Ni-MOF adsorption material by ultrasonic-assisted solvothermal method, the steps are as follows:

[0026] ① First measure 20ml of DMF and 10ml of EtOH as solvent;

[0027] ②Weigh 1-4g of terephthalic acid as organic ligand, 1.74g of Ni(NO 3 ) 2 ·6H 2 O as a coordinated metal ion;

[0028] ③ Add 1ml of acetic acid and 0.01g of benzoic acid as molecular size regulators to synthesize Ni-MOF with smaller size;

[0029] ④ After adding all the medicines, stir them with a magnetic stirrer until they are completely dissolved, and then place them in an ultrasonic instrument for 80 minutes to disperse the medicines evenly and promote crystallization;

[0030] ⑤ Finally, pour the mixed solution into a polytetrafluoroethylene-lined reaction kettle, and react in a constant temperature drying oven at 160°C for 24 hours;

[0031] ⑥ After the reaction is finished and cooled to room temperature naturally, wash 3 times with water, 3 times with ethanol, and 1 t...

Embodiment 2

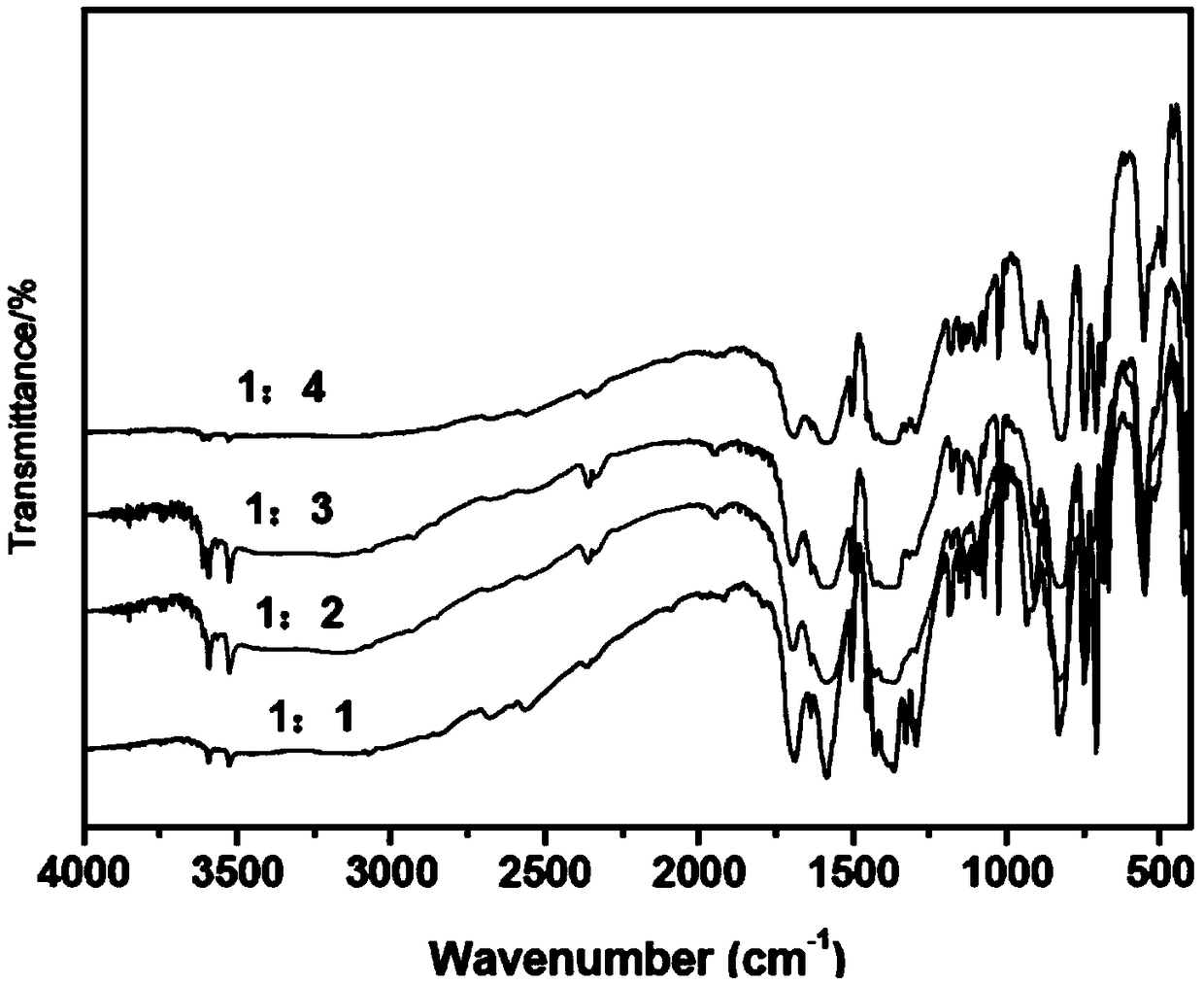

[0035] Structural characterization of Ni-MOF adsorption materials

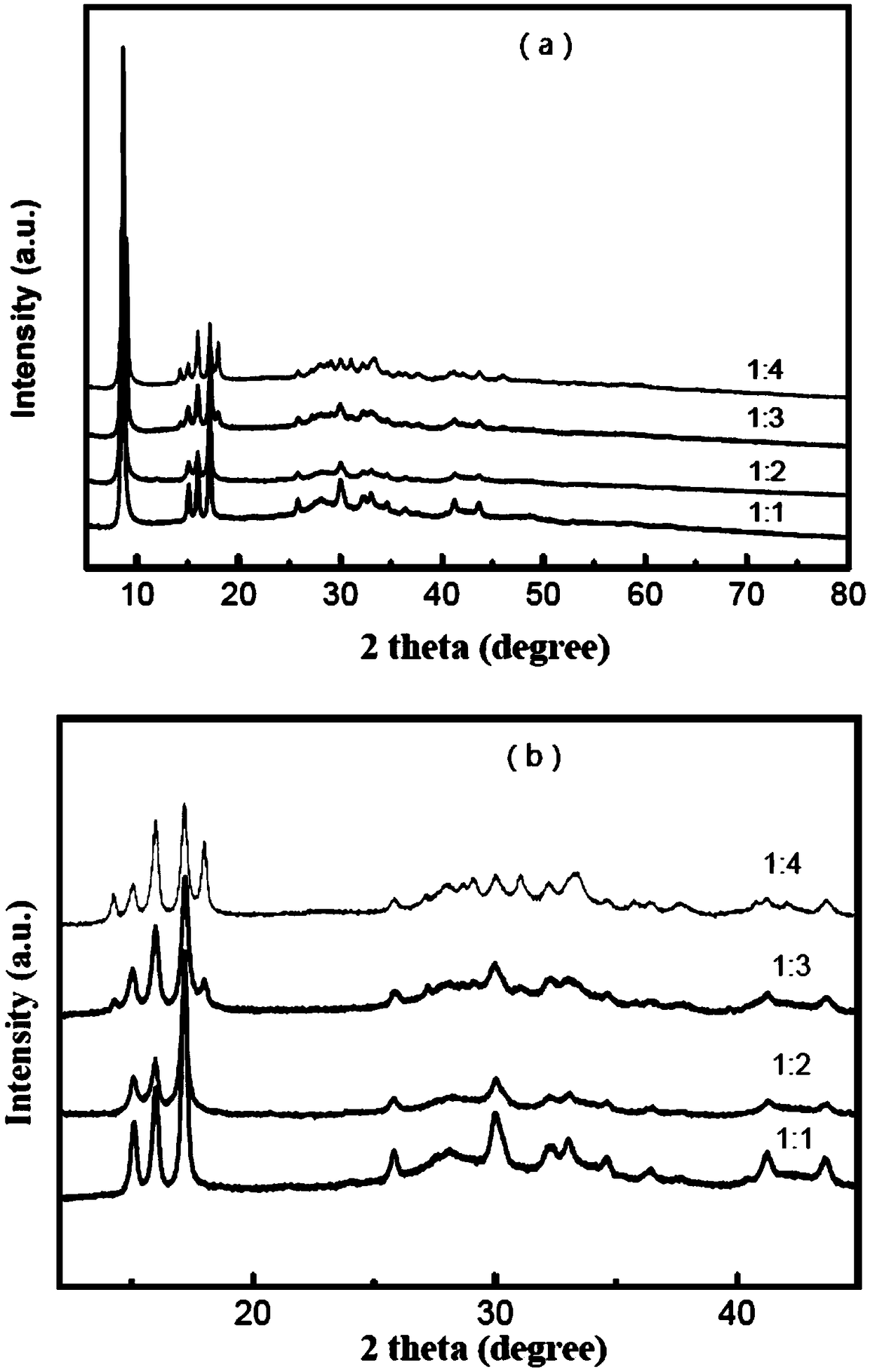

[0036] 1. XRD analysis

[0037] figure 1 It is the XRD patterns of different ratios of Ni-MOF synthesized by solvothermal method (b is a partial cut-off curve in a). From figure 1 It can be seen from the figure that the diffraction peak positions of samples synthesized with different ratios are all at 2θ=8°, and there are fewer miscellaneous peaks, and the ratios are 1:1, 1:2, 1:3, 1:4, indicating that the four samples have a similar crystal structure, but consist of figure 1 It can be seen that when Ni 2+ The peak that appears when the ratio with terephthalic acid is 1:2 is the most significant.

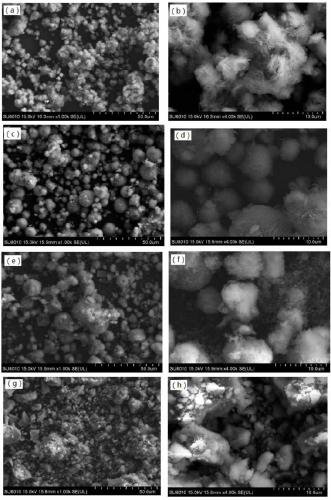

[0038] 2. SEM analysis

[0039] figure 2 SEM images of different proportions of Ni-MOF synthesized by solvothermal method, figure 2 a, c, e, g represent Ni(NO 3 ) 2 ·6H 2 The molar ratio of O to terephthalic acid is 1:1, 1:2, 1:3, 1:4, respectively, figure 2 b, d, f, h are respectively figure 2 High...

Embodiment 3

[0046] Performance test of Ni-MOF adsorption material

[0047] The Ni-MOF samples synthesized in Example 1 (1:2 ratio) were added to the Cu-containing 2+ and Pt 2+ After 12 hours, the precipitate was suction filtered, washed and dried before testing. The element content in each sample was obtained by emax energy spectrum analysis method, Figure 5 is the emax energy spectrum in the sample before adsorption, Figure 6 a, b are the adsorbed Cu 2+ After the emax energy spectrum and element content table, Figure 7 a, b are adsorbed Pt 2+ After comparing the emax energy spectrum and element content table, it is found that Ni-MOF has a good effect on Cu 2+ and Pt 2+ have a certain degree of adsorption. Among them, for Cu 2+ The adsorption is more obvious.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com