Preparation method and application of an in-situ supported metal mesoporous carbon microsphere catalyst

A technology for supporting metals and catalysts, which is applied in the preparation and application field of in-situ supported metal mesoporous carbon microsphere catalysts, can solve the problems of reducing catalyst selectivity, product purity, unfavorable product separation and purification, etc., and achieves easy reuse and shortens the preparation time Effects of Time, Strong Industrialization Prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

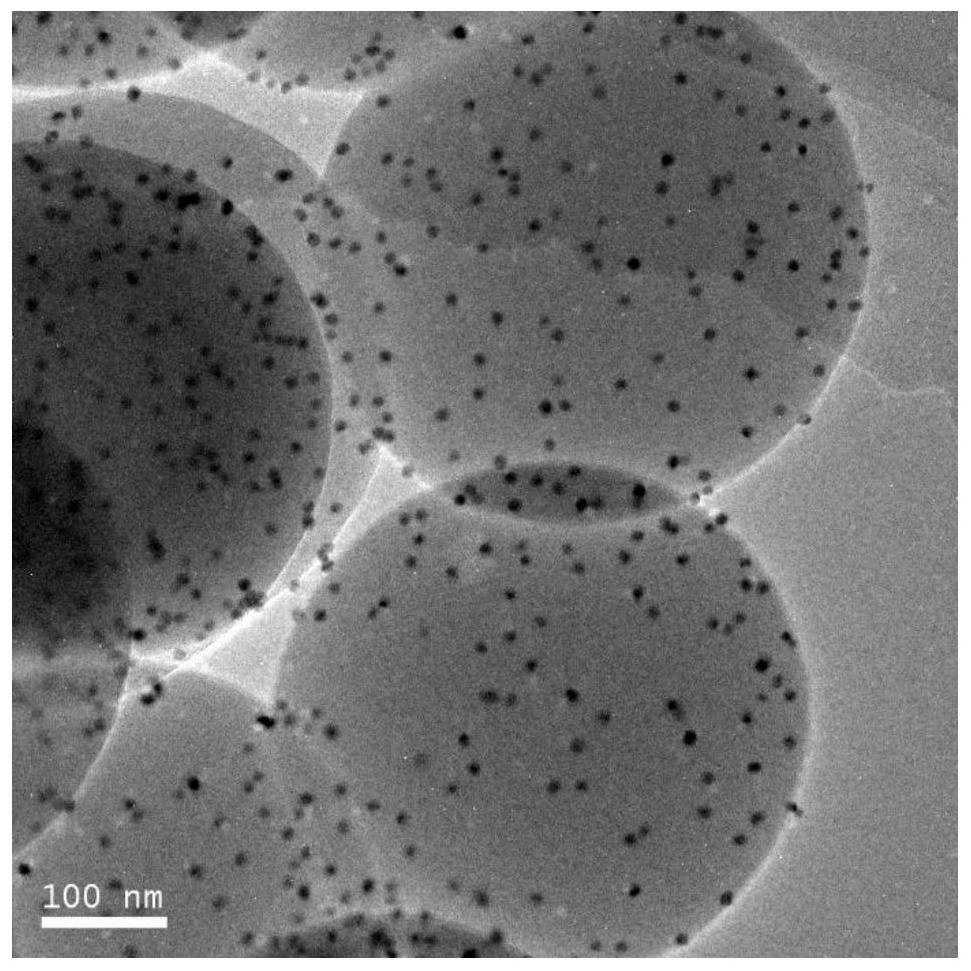

Image

Examples

Embodiment 1

[0036] Measure 0.2ml of 0.04g / mL Pd(NH 3 ) 4 Cl 2 Aqueous solution, 0.2mL of ammonia water with a mass concentration of 25% to 28%, 40mL of ethanol, and 100mL of deionized water are fully stirred, and then 1.8g of resorcinol is added, stirred until completely dissolved, and then slowly added dropwise with 0.8mL Formaldehyde aqueous solution with a mass concentration of 37-40% was stirred at 20°C for 12 hours, then transferred to a hydrothermal reaction kettle and kept at 100°C for 30h, and then centrifuged and washed to obtain a reddish-brown polymer solid powder. Dry at 45°C for 24 hours at a relative vacuum of -0.099~-0.05MPa.

[0037] Then the solid obtained above was reduced with hydrogen-argon mixed gas (hydrogen gas fraction is 10%), the process was kept at 200°C for 2 hours, at 600°C for 3 hours, and at 800°C for 4 hours, (wherein the heating program was: 1°C / min from room temperature to 200°C, 5°C / min from 200°C to 600°C, 10°C / min from 600°C to 800°C, space velocity...

Embodiment 2

[0039] Measure 0.2ml of 0.04g / mLPd(NH 3 ) 4 Cl 2 Aqueous solution, 0.5mL of ammonia water with a mass concentration of 25% to 28%, 50mL of ethanol, and 150mL of deionized water are fully stirred, and then 1.5g of resorcinol is added, and after stirring until completely dissolved, slowly add 0.5mL of Formaldehyde aqueous solution with a mass concentration of 37-40% was stirred at 25°C for 15 hours, then transferred to a hydrothermal reaction kettle at 150°C for 20 hours, and then centrifuged to obtain a reddish-brown polymer solid powder. Dry at 90°C for 12 hours at a relative vacuum of -0.099 to -0.05MPa.

[0040] Then the solid obtained above was reduced with hydrogen-argon mixed gas (hydrogen gas fraction is 10%), the process was kept at 200°C for 1 hour, at 600°C for 3 hours, and at 800°C for 4 hours, (wherein the heating program was: 1°C / min from room temperature to 200°C, 5°C / min from 200°C to 600°C, 10°C / min from 600°C to 800°C, space velocity not less than 30h -1 ) ...

Embodiment 3

[0042] Measure 0.2ml of 0.04g / mLPd(NH 3 ) 4 Cl 2 Aqueous solution, 0.3mL of ammonia water with a mass concentration of 25% to 28%, 30mL of ethanol, and 60mL of deionized water were fully stirred, then 2.9g of resorcinol was added, and after stirring until completely dissolved, 2mL of Formaldehyde aqueous solution with a mass concentration of 37-40% was stirred at 30°C for 20 hours, then transferred to a hydrothermal reaction kettle at 100°C for 12 hours, and then centrifuged and washed to obtain a reddish-brown polymer solid powder. Dry at 80°C for 16 hours at a relative vacuum of -0.099 to -0.05MPa.

[0043] Then the solid obtained above was reduced with hydrogen-argon mixed gas (hydrogen gas fraction is 10%), the process was kept at 200°C for 2 hours, at 600°C for 3 hours, and at 800°C for 4 hours, (wherein the heating program was: 1°C / min from room temperature to 200°C, 5°C / min from 200°C to 600°C, 10°C / min from 600°C to 800°C, space velocity not less than 30h -1 ) to o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com