A preparation method of nano-magnesia and a nano-magnesia-nanofiber composite felt as well as its preparation method and application

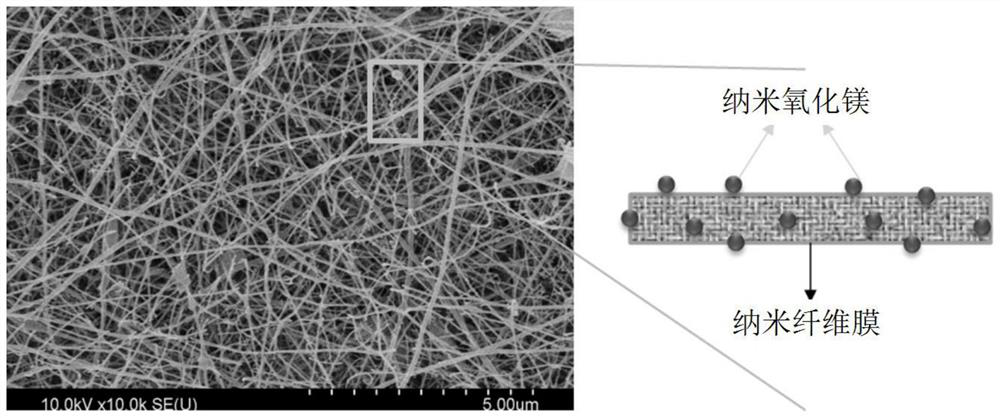

A nano-magnesium oxide and nano-fiber technology is applied in the field of decontamination, which can solve the problems of easy aggregation and inconvenience in use, and achieve the effects of solving inconvenient use, convenient use and avoiding easy agglomeration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0023] The invention provides a kind of preparation method of nano magnesium oxide, comprises the following steps:

[0024] (1) adding the sodium carbonate aqueous solution dropwise to the magnesium nitrate alcohol solution to obtain the sol;

[0025] (2) The sol obtained in the step (1) is subjected to standing aging, filtering, washing and drying in sequence to obtain a xerogel;

[0026] (3) Sintering the dry gel obtained in the step (2) to obtain nano magnesium oxide.

[0027] In the present invention, the sodium carbonate aqueous solution is added dropwise to the magnesium nitrate alcohol solution to obtain the sol.

[0028] In the present invention, the dropping temperature is preferably -10°C to 4°C, more preferably -8°C to 2°C, more preferably -6°C to 0°C, even more preferably -4°C to -2°C ℃. In the present invention, the sodium carbonate aqueous solution is preferably added dropwise to the magnesium nitrate alcohol solution at the above temperature, which is conduci...

Embodiment 1

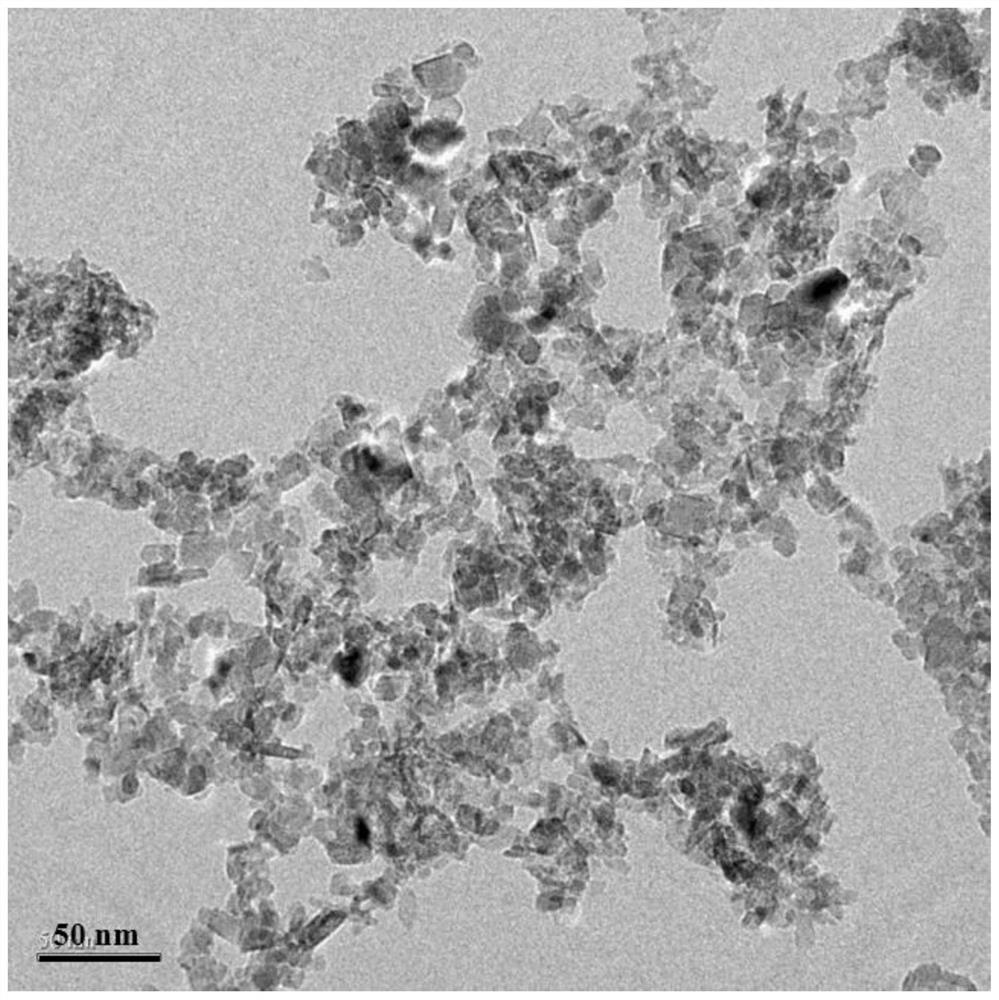

[0078] 6.3g Mg(NO 3 ) 2 ·6H 2 O dissolved in 25 mL ethylene glycol, 1.3 g Na 2 CO 3 Dissolved in 12.5mL of water, after complete dissolution, the Na 2 CO 3 The solution was added dropwise to Mg(NO 3 ) 2 Ultrasound was carried out in the solution at the same time, and ultrasonication was continued for 10 minutes after the addition was completed. After the ultrasonication was completed, it was left to stand at room temperature for 5 hours, filtered and washed with water two to three times, and the obtained precipitate was vacuum-dried overnight, and then calcined in a mini box furnace: calcining temperature 310 ℃, the calcination time is 3 hours, and the sample is taken out after cooling down to obtain nano-magnesia.

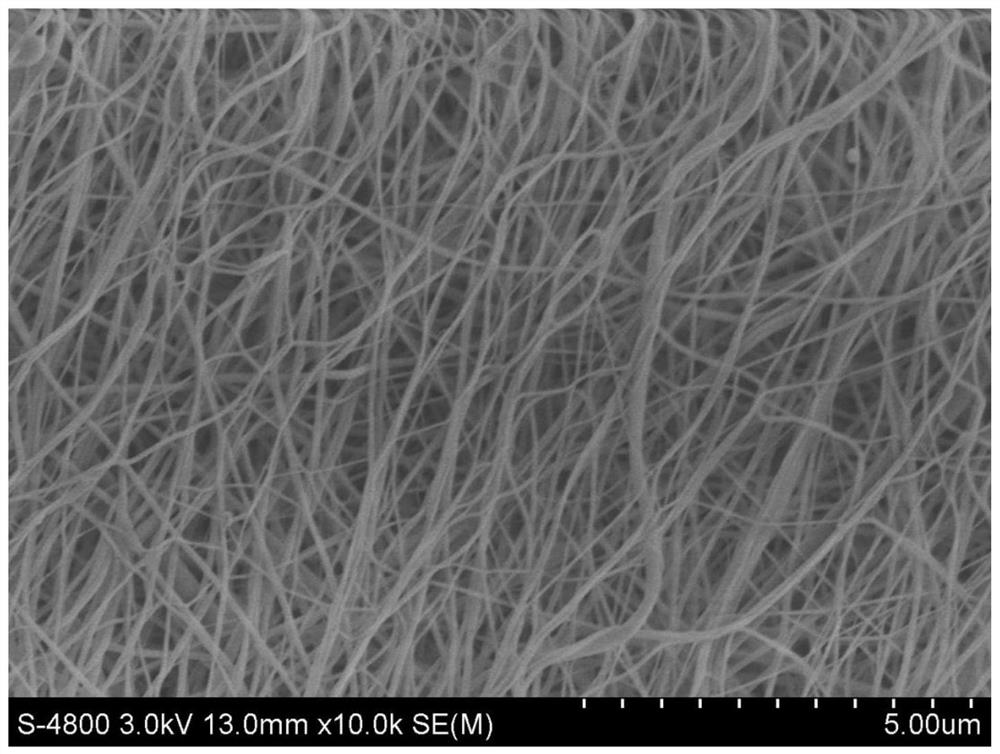

[0079] Nylon-6 electrospun fiber membrane, dopamine, polyethyleneimine and trimethylolaminomethane are mixed to obtain a mixed material liquid, wherein nylon-6 electrospun fiber membrane, dopamine, polyethyleneimine and trimethylol The ratio of aminomethan...

Embodiment 2

[0082] 12.3g Mg(NO 3 ) 2 ·6H2 O dissolved in 25 mL ethylene glycol, 2.3 g Na 2 CO 3 Dissolved in 12.5mL of water, after complete dissolution, the Na 2 CO 3 The solution was added dropwise to Mg(NO 3 ) 2 Ultrasound was carried out in the solution at the same time, and ultrasonication was continued for 20 minutes after the addition was completed. After the ultrasonication was completed, it was left to stand at room temperature for 8 hours, filtered and washed with water two to three times, and the obtained precipitate was vacuum-dried overnight, and then calcined in a mini box furnace: calcination temperature 410 ℃, the calcination time is 2 hours, and the sample is taken out after cooling down to obtain nano-magnesia.

[0083] Nylon-6 electrospun fiber membrane, dopamine, polyethyleneimine and trimethylolaminomethane are mixed to obtain a mixed material liquid, wherein nylon-6 electrospun fiber membrane, dopamine, polyethyleneimine and trimethylol The ratio of aminometha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com