High-efficiency slow-release carbon source modified corn cob, preparation method and application thereof

A slow-release carbon source and corn cob technology, which is applied in chemical instruments and methods, water treatment of special compounds, sustainable biological treatment, etc., can solve the problem of unstable release rate of slow-release carbon source, and achieve low quality loss and easier Effect of contact and promotion of decomposition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Step 1: Grinding and sieving the corncobs in a pulverizer to obtain samples with a required particle size of about 12 mm, washing them and placing them in natural conditions to air-dry for later use;

[0027] Step 2, taking 8 parts of corncobs and 90 parts of a mixed solution containing 1v / v% hydrogen peroxide and 3w / v% sodium hydroxide, and bathing in a constant temperature water bath at 95-100°C for 4 hours;

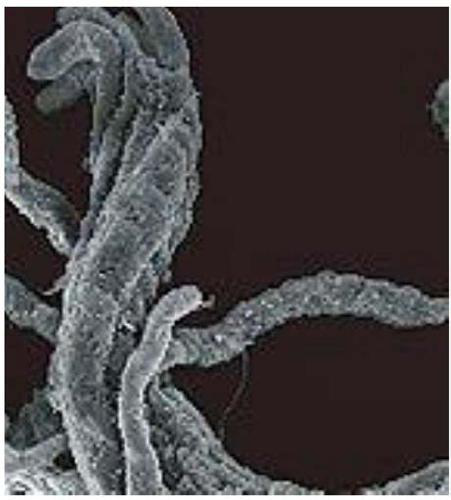

[0028] Step 3: Cool the reaction solution in Step 2 to room temperature, wash, neutralize and centrifuge in a low-speed centrifuge at 1800 rpm for 3 minutes, and dry at low temperature to constant weight to obtain a slow-release carbon source. Depend on figure 1 and figure 2 It can be seen from the comparison that the cellulose structure of the untreated corncob structure is dense, and the cellulose, hemicellulose and lignin are cross-linked together. This high degree of cross-linking greatly reduces the contact degree of cellulose and cellulase; After modifi...

Embodiment 2

[0030] Step 1: Grinding and sieving the corncobs in a pulverizer to obtain samples with a required particle size of 9-10 mm, washing them and placing them in natural conditions to air-dry for later use;

[0031] Step 2, take 10 parts of corncobs and 80 parts of a mixed solution containing 1v / v% hydrogen peroxide and 2w / v% sodium hydroxide, and bathe in a constant temperature water bath at 90°C for 2 hours;

[0032] Step 3: Cool the reaction solution in Step 2 to room temperature, wash it, and centrifuge it in a low-speed centrifuge at 1500 rpm for 5 minutes after neutralization, and dry it to a constant weight at low temperature to obtain a slow-release carbon source. The prepared high-efficiency slow-release The degree of cross-linking among the modified corn cob fibers by releasing carbon sources is reduced, the structure is loose and porous, the porosity and pore size are increased, most of the lignin and part of the cellulose are removed, and the lattice structure between t...

Embodiment 3

[0034] Step 1: Grinding and sieving the corncobs in a pulverizer to obtain samples with a required particle size of 12-15 mm, washing them and placing them in a natural condition to air-dry for later use;

[0035] Step 2, taking 9 parts of corncobs and 85 parts of a mixed solution containing 2v / v% hydrogen peroxide and 1.5w / v% sodium hydroxide, and bathing in a constant temperature water bath at 98-100°C for 2.5 hours;

[0036] Step 3: Cool the reaction solution in step 2 to room temperature, wash it, and centrifuge it in a low-speed centrifuge at 1200 rpm for 10 minutes after neutralization, and dry it at low temperature to constant weight to obtain a slow-release carbon source. The prepared high-efficiency slow The degree of cross-linking among the modified corn cob fibers by releasing carbon sources is reduced, the structure is loose and porous, the porosity and pore size are increased, most of the lignin and part of the cellulose are removed, and the lattice structure betwe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com