Automatic sludge dewatering system and method

A sludge dehydration and sludge technology, which is applied in the direction of dehydration/drying/concentrated sludge treatment, etc., can solve the problems of large influence of natural conditions, large floor area, and reduced moisture content, and achieve low cost of chemicals and short processing time , good dehydration effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

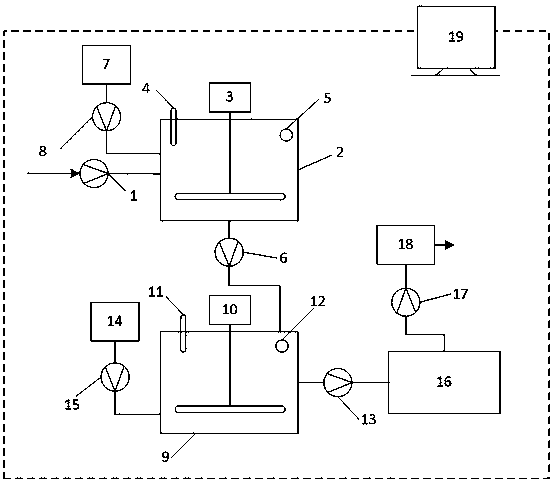

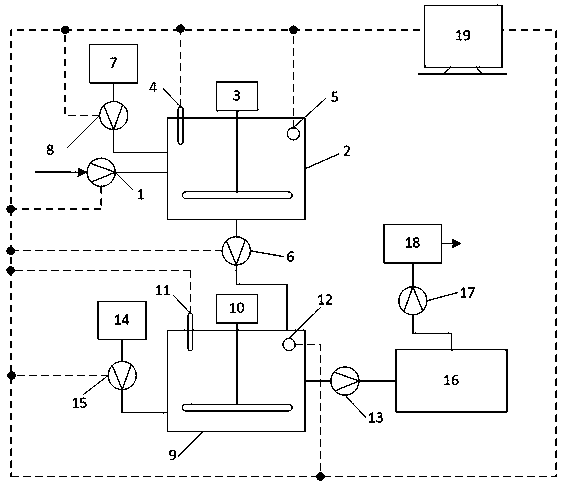

Method used

Image

Examples

Embodiment 1

[0055] Turn on the sludge inlet pump, and the sludge solution with a water content of 97.5% in the sewage plant will be pumped into the No. Hydrochloric acid solution, the dosing amount is 3.3ml / 100ml, the pH of the sludge solution after dosing is 1, react for 20min, after the reaction, pump the sludge solution in the No. 1 reaction tank into the No. 2 reaction tank, and the No. 1 reaction The lower limit of the liquid level of the tank is 0. When the sludge solution in the No. 1 reaction tank is emptied, the sludge inlet pump is turned on again; when the liquid level of the No. Pump calcium carbonate solution into the No. 2 reaction tank, the dosing amount is 1.8ml / 100ml, the pH of the sludge solution after dosing is 8, and react for 40 minutes. After the reaction, pump the sludge solution in the No. 2 reaction tank into the buffer In the tank, the lower limit of the liquid level of the No. 2 reaction tank is 0. When the sludge solution in the No. 2 reaction tank is emptied, ...

Embodiment 2

[0057] The sludge solution with a moisture content of 98% in the sewage plant is pumped into the No. 1 reaction tank. When the liquid level of the No. 1 reaction tank is higher than the preset upper limit, the sludge inlet pump is turned off. When the liquid level of the No. 1 reaction tank is lower than the preset At the lower limit, turn on the mud inlet pump again; pump dilute sulfuric acid solution into the No. 1 reaction tank, the dosing amount is 1.1ml / 100ml, the pH setting upper limit of No. 1 reaction tank is 5, and the lower limit is 4, and the sludge solution The residence time in the No. 1 reaction tank is 15min; the sludge in the No. 1 reaction tank is pumped into the No. 2 reaction tank. When the liquid level of the No. 2 reaction tank is higher than the preset upper limit, the No. 1 discharge pump is closed. When the liquid level of the No. 2 reaction tank is lower than the preset lower limit, turn on the No. 1 discharge pump again; pump calcium oxide solution int...

Embodiment 3

[0059] The sludge solution with a moisture content of 97% in the sewage plant is pumped into the No. 1 reaction tank. When the liquid level of the No. 1 reaction tank is higher than the preset upper limit, the sludge inlet pump is turned off. When the liquid level of the No. 1 reaction tank is lower than the preset At the lower limit, open the mud inlet pump again; pump dilute sulfuric acid solution into the No. 1 reaction tank, and the dosing amount is 2ml / 100ml. The residence time in No. 1 reaction tank is 30min; the sludge in No. 1 reaction tank is pumped into No. When the liquid level of the No. reaction tank is lower than the preset lower limit, the No. 1 discharge pump is turned on again; the calcium oxide solution is pumped into the No. 7.5, set the lower limit as 6.5, the residence time of the sludge solution in the No. The moisture content of the dehydrated sludge was determined to be 62%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com