A method and system for hydrothermal treatment of concentrated sludge

A technology for thickening sludge and hydrothermal treatment, applied in the direction of sludge treatment through temperature control, can solve the problems of increasing equipment investment cost, increasing energy consumption, increasing processing procedures, etc., and achieves small footprint, simple structure, and economical treatment. effect of the program

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

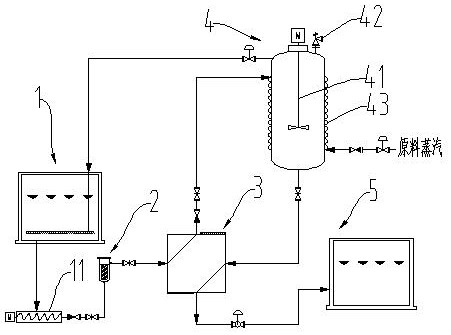

[0031] Such as figure 1 As shown, this embodiment provides a thickened sludge hydrothermal treatment system, which includes a thickened sludge tank 1 , a filter 2 , a heat exchanger 3 and a hydrothermal reactor 4 connected in sequence. The heat exchanger 3 is also connected with an anaerobic buffer tank 5 .

[0032] Thickened sludge pool 1 is used to collect and store concentrated sludge. A feed pump 11 is arranged between the thickened sludge tank 1 and the filter 2 to transport the thickened sludge in the thickened sludge tank 1 to the filter 2 for filtering. The filter 2 traps impurities such as particles, fibers and hair in the sludge to prevent the heat exchanger 3 from being blocked. The heat exchanger 3 can be a spiral plate heat exchanger or a casing heat exchanger in the prior art.

[0033] The heat exchanger 3 has a cold source medium outlet and a cold source substrate inlet, as well as a heat source medium outlet and a heat source substrate inlet. The outlet of ...

Embodiment 2

[0037] This embodiment provides a method for hydrothermal treatment of concentrated sludge, which is used in conjunction with the hydrothermal treatment system for concentrated sludge provided in Example 1, and is especially suitable for hydrothermal treatment of concentrated sludge, which includes the following steps:

[0038] Step 1: Collect the concentrated sludge in the concentrated sludge tank, use the released hydrothermal steam to perform a first-level pre-heating, and then transport it to the filter, filter it, enter the heat exchanger as a cold source medium, and exchange it through the heat exchanger After preheating, it enters the hydrothermal reactor for hydrothermal reaction.

[0039] Step 2: After the hydrothermal reaction, recover the released hydrothermal steam to preheat the concentrated sludge, and transport the liquid material as the heat source medium to the heat exchanger for heat exchange and cooling before collecting and processing.

Embodiment 3

[0041] This embodiment provides a method for hydrothermal treatment of concentrated sludge, which is used in conjunction with the hydrothermal treatment system for concentrated sludge provided in Example 1, and is especially suitable for hydrothermal treatment of concentrated sludge, which includes the following steps:

[0042] Step 1: Collect the sludge with a water content of 93-98% in the thickened sludge tank, use the released water heat steam to perform a first-stage pre-heating to 50-60°C, and then transport it to the filter, through a filter diameter of 8- It is filtered through a 12mm filter, and then enters the heat exchanger as a cold source medium. After heat exchange in the heat exchanger, it is pre-heated to 130-160°C and then enters the hydrothermal reactor for hydrothermal reaction. The heat source of the hydrothermal reaction is saturated steam. , The hydrothermal reaction is carried out under stirring conditions, and the reaction temperature is 180-200°C.

[0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com