Tunnel kiln superposition sintering method for foamed ceramic lightweight boards

A technology of foamed ceramics and tunnel kiln, which is applied in the production of ceramic materials, ceramic products, and applications. It can solve the problems of poor overall product uniformity, difficult oxidation of the formula system, and long firing cycle, so as to reduce the oxidation reaction stage. Time, excellent quality, and reduced floor space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0072] (1) Formula: tile polishing waste 95.5%, foaming agent 0.5%, manganese dioxide stabilizer 4%.

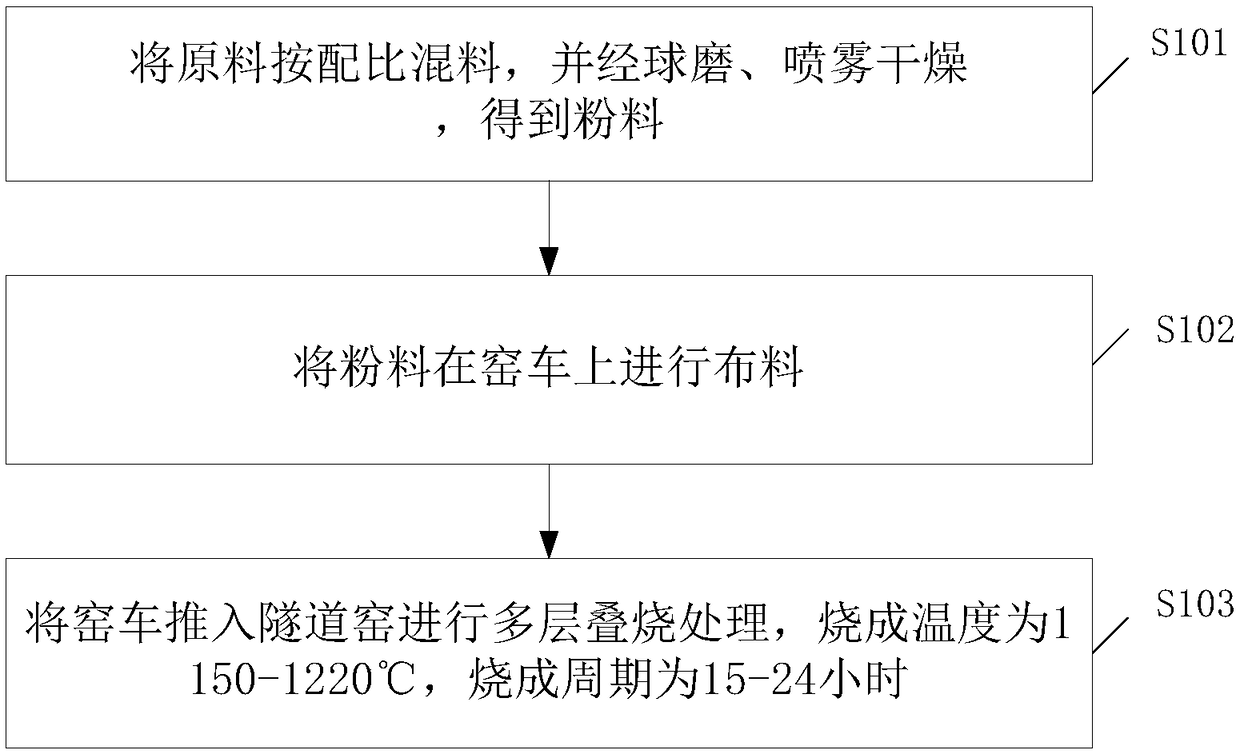

[0073] (2) Preparation method:

[0074] The raw materials are mixed according to the proportion, and the powder is obtained through ball milling;

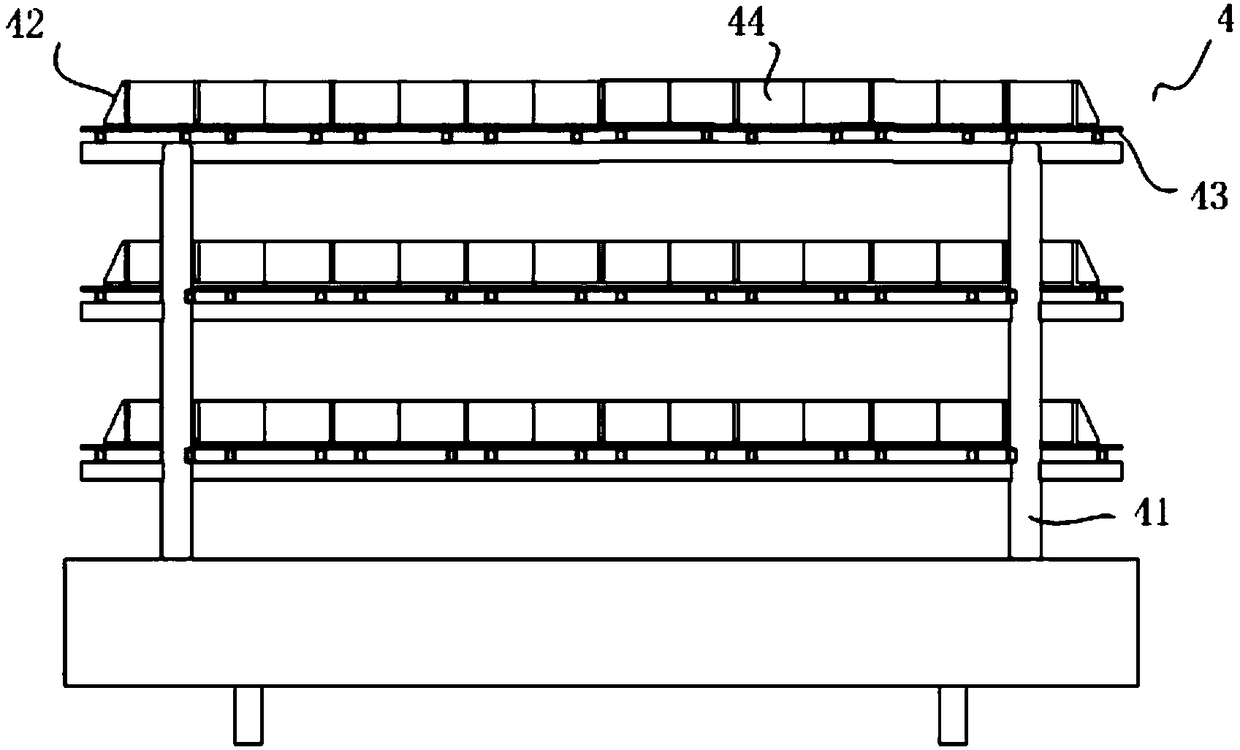

[0075] Distributing the powder on the kiln car, wherein the kiln car includes a support, and the support is provided with a three-layer sagger, and the sagger is used for the distribution of the powder;

[0076] Push the kiln car into the tunnel kiln for three-layer superposition firing treatment. The firing method is as follows:

[0077] (a) Raise the temperature to 800°C and keep it at 800°C for 20 minutes, wherein the heating rate from 0°C to 400°C is 10°C / min, and the heating rate from 400°C to 800°C is 3°C / min;

[0078] (b) Raise the temperature to 1150°C and keep it at the highest temperature for 40 minutes, wherein the heating rate from 800°C to 1150°C is 3°C / min;

[0079] (c) Slowly lower the temperature, the cooling ra...

Embodiment 2

[0081] (1) Formula: tile polishing waste 90%, clay 1%, feldspar 8.8%, foaming agent 0.1%, stabilizer 0.1%.

[0082] (2) Preparation method:

[0083] The raw materials are mixed according to the proportion, and the powder is obtained through ball milling;

[0084] Distributing the powder on the kiln car, wherein the kiln car includes a support, and the support is provided with a three-layer sagger, and the sagger is used for the distribution of the powder;

[0085] Push the kiln car into the tunnel kiln for three-layer superposition firing treatment. The firing method is as follows:

[0086] (a) Raise the temperature to 820°C and keep it at 820°C for 15 minutes, wherein the heating rate from 0°C to 400°C is 15°C / min, and the heating rate from 400°C to 820°C is 5°C / min;

[0087] (b) Raise the temperature to 1170°C and keep it at the highest temperature for 30 minutes, wherein the heating rate from 820°C to 1170°C is 4°C / min;

[0088] (c) Slowly lower the temperature, the cool...

Embodiment 3

[0090] (1) Formula: tile polishing waste 92%, clay 5%, feldspar 2%, foaming agent 0.2%, stabilizer 0.8%.

[0091] (2) Preparation method:

[0092] The raw materials are mixed according to the proportion, and the powder is obtained through ball milling;

[0093] Distributing the powder on the kiln car, wherein the kiln car includes a support, and the support is provided with a three-layer sagger, and the sagger is used for the distribution of the powder;

[0094] Push the kiln car into the tunnel kiln for three-layer superposition firing treatment. The firing method is as follows:

[0095] (a) Raise the temperature to 830°C and keep it at 830°C for 25 minutes, wherein the heating rate from 0°C to 400°C is 15°C / min, and the heating rate from 400°C to 830°C is 5°C / min;

[0096] (b) Raise the temperature to 1180°C, and keep it at the highest temperature for 0-60min, wherein, the heating rate from 830°C to 1180°C is 5°C / min;

[0097] (c) Slowly lower the temperature, the cooling...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com