Electrochromic compound, use, and electrochromic device prepared therefrom and use

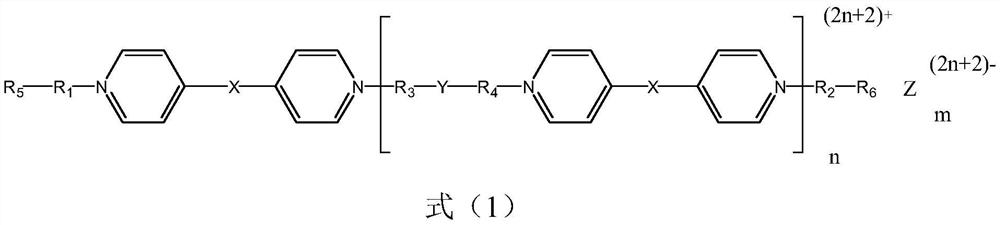

An electrochromic device and electrochromic technology, which are applied in chemical instruments and methods, compounds of group 5/15 elements of the periodic table, color-changing fluorescent materials, etc., can solve the problems of short color-changing response time and low preparation cost, etc. Achieve the effects of wide color changing range, high light transmittance difference and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] Compound I was prepared by the following steps:

[0055] Step (1), 4-pyridineboronic acid pinacol ester (2.01g, 9.8mmol), tetrakis (triphenylphosphine) palladium (407mg, 0.352mmol), potassium phosphate (5.95g, 28mmol) was added in the 250ml flask, Add 70mL of 1,4-dioxane solution containing 2,5-dibromothiophene (394μL, ρ=2.15mg / mL, 847mg, 3.61mmol) in a nitrogen atmosphere, heat to 90°C, react for 72h, and the reaction is complete After the reaction solution was cooled to room temperature, the filter residue was washed with chloroform, the filtrate was spin-dried in a rotary evaporator, and finally purified by silica gel column chromatography (the eluent was a mixed solution with a mass ratio of chloroform:methanol=200:1) to obtain a yellow solid Namely compound 1 (575mg), yield 69%;

[0056] Step (2), the compound 1 (476mg, 2mmol) obtained in step (1) and diethyl bromoethylphosphate (490mg, 2mmol) were dissolved in 10mL DMF, heated to 90°C, after 24h of reaction, the ...

Embodiment 2

[0065] Compound II was prepared by the following steps:

[0066] Step (1), 3,4-ethylenedioxythiophene (1.42g, 10mmol) was dissolved in 30mL DMF, and cooled to 0°C with an ice bath, N-bromosuccinimide (3.78g, 21mmol) was dissolved In 30mL of DMF, slowly drop into the above solution with a constant pressure dropping funnel. After the dropwise addition, the reaction solution was stirred at room temperature for 2h. After the reaction, 100mL of ice water was slowly added to the reaction solution to produce a large amount of light yellow solid , the product was filtered under reduced pressure, and the filter residue was washed three times with 15 mL of deionized water to obtain 2.85 g of the product, namely compound 4, with a yield of 95%;

[0067] Step (2), 4-pyridineboronic acid pinacol ester (2.01g, 9.8mmol), tetrakis (triphenylphosphine) palladium (407mg, 0.352mmol), potassium phosphate (5.95g, 28mmol) was added in a 250mL flask, Add 70mL of 1,4-dioxane solution containing comp...

Embodiment 3

[0077] The only difference from Example 1 is that compound 8 is used instead of 2,5-dibromothiophene in step (1), and the molar amount of compound 8 added is the same as that of 2,5-dibromothiophene.

[0078] Compound 8 has the following structure:

[0079]

[0080] Embodiment 3 obtains compound III, and compound III has the following structure:

[0081]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com