Aspartic polyurea resin composition with high durability, abrasion resistance, water resistance and corrosion resistance

A kind of technology of aspartame polyurea resin and wear resistance, which is applied in the field of aspartame polyurea resin composition, can solve the problems of tensile elongation, chemical resistance, weather resistance, poor durability, surface cracking and yellowing Achieve excellent chemical resistance and shorten construction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

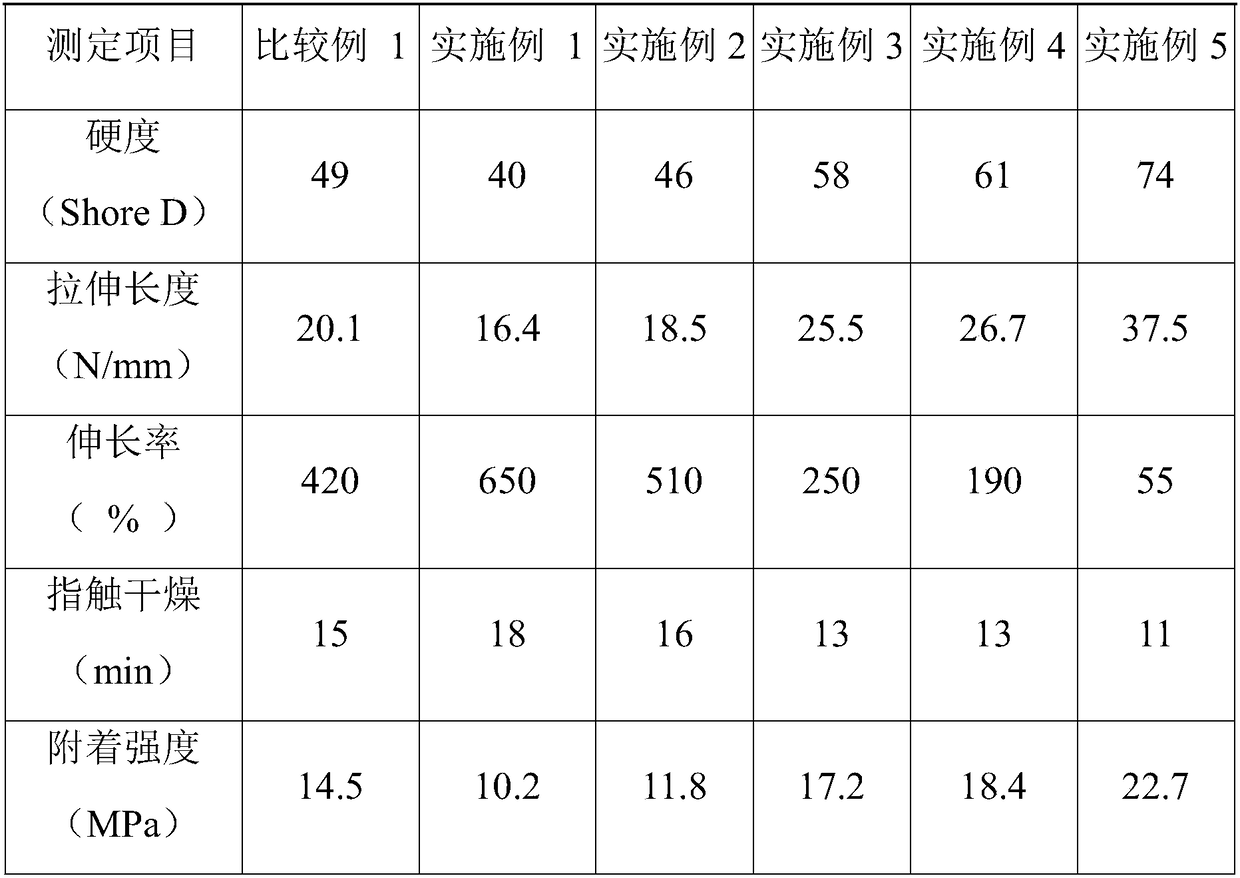

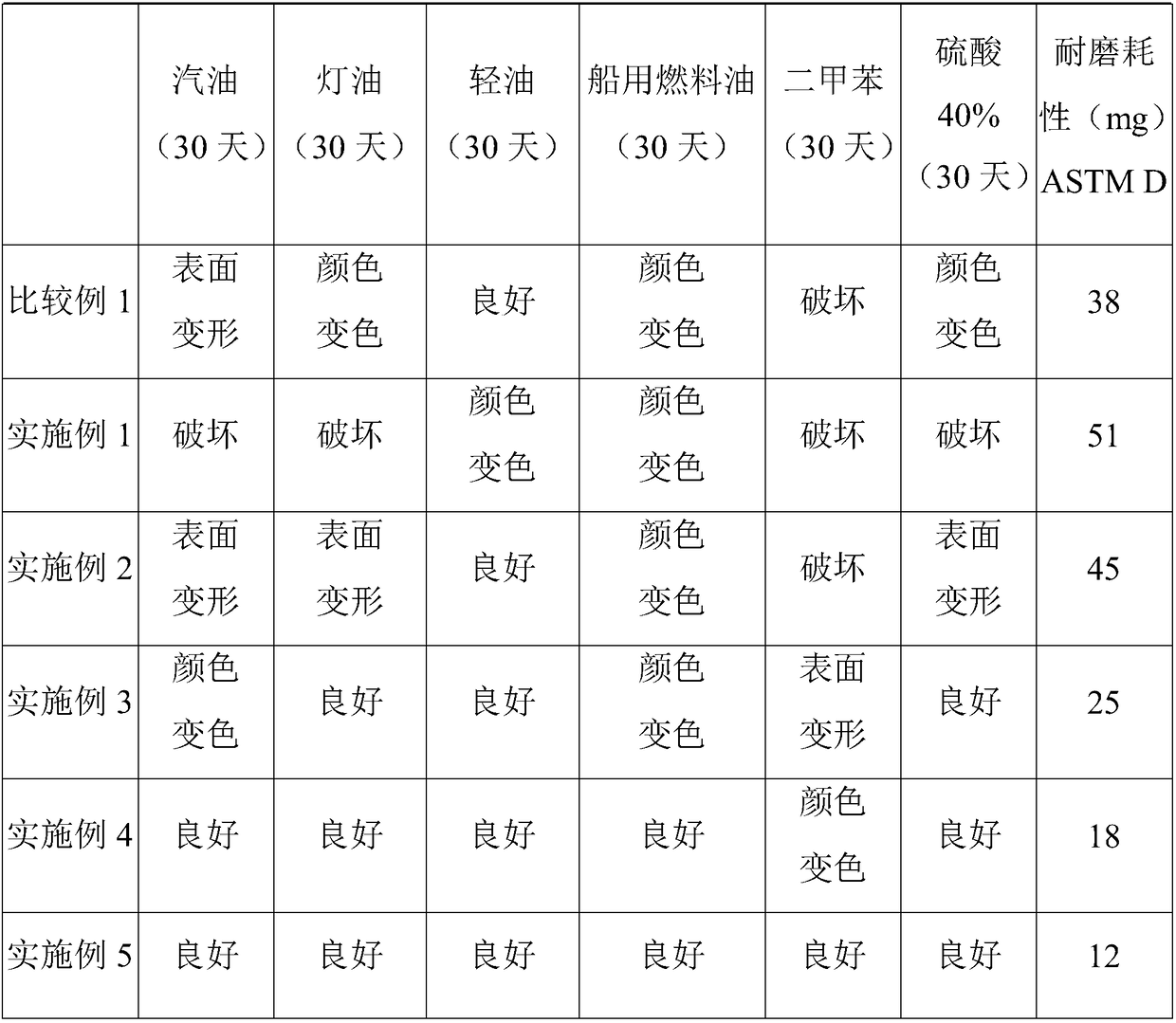

Embodiment 1

[0019] High durability, wear resistance and waterproof and anti-corrosion aspart polyurea resin composition, including main agent and curing agent, the main agent and curing agent are mixed in a volume ratio of 1:1;

[0020] Wherein, the main ingredient includes: 49% of NH-1420 (polyaspartic acid ester produced by Bayer), 1% of tri-(2-chloroisopropyl) phosphate with a molecular weight of 327.4, 1% of D -2000 (polyetheramine produced by BASF) 44%, pigment 5%; the curing agent is a polyisocyanate prepolymer with an NCO% content of 13%.

Embodiment 2

[0022] High durability, wear resistance and waterproof and anti-corrosion aspart polyurea resin composition, including main agent and curing agent, the main agent and curing agent are mixed in a volume ratio of 1:1;

[0023] Wherein, the main ingredient includes: 54% of NH-1420 (polyaspartic acid ester produced by Bayer), 1% of tri-(2-chloroisopropyl) phosphate with a molecular weight of 327.4, D -2000 (polyetheramine produced by BASF) 40%, pigment 5%; the curing agent is a polyisocyanate prepolymer with an NCO% content of 14%.

Embodiment 3

[0025] High durability, wear resistance and waterproof and anti-corrosion aspart polyurea resin composition, including main agent and curing agent, the main agent and curing agent are mixed in a volume ratio of 1:1;

[0026] Wherein, the main ingredient includes: 70% of NH-1420 (polyaspartic acid ester produced by Bayer), 1% of tri-(2-chloroisopropyl) phosphate with a molecular weight of 327.4, D -2000 (polyetheramine produced by BASF) 24%, pigment 5%; the curing agent is a polyisocyanate prepolymer with an NCO% content of 17%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile length | aaaaa | aaaaa |

| Tensile length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com