Mesoporous silicon dioxide and cellulose blended membrane protected by buffer solution, preparation method and application thereof

A mesoporous silica and buffer solution technology, applied in chemical instruments and methods, bandages, water/sludge/sewage treatment, etc., can solve problems such as structural damage, achieve high adsorption performance, prevent wound infection, and react products Gentle and non-polluting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

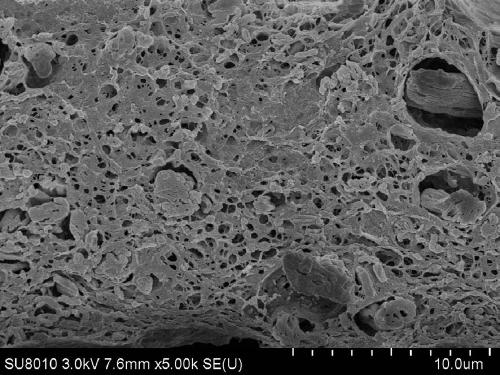

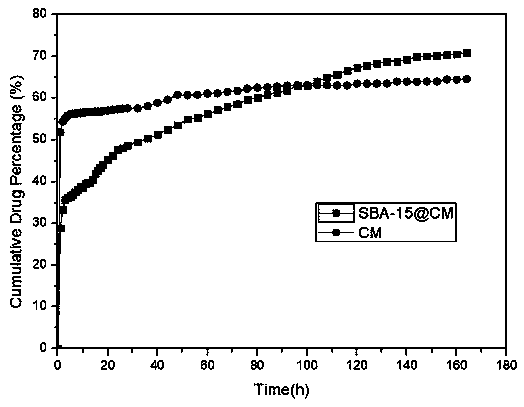

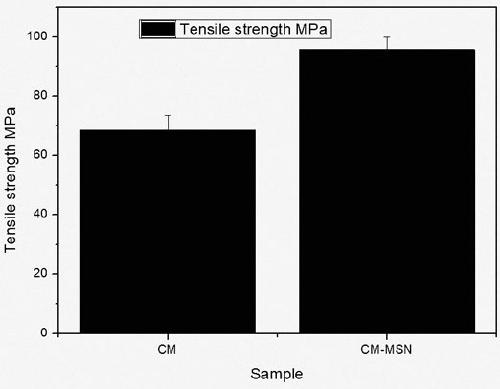

Image

Examples

Embodiment 1

[0027] A method for preparing a mesoporous silica and cellulose blend membrane protected by a buffer solution, the specific steps are as follows:

[0028] 1) Configure 0.5mol / L phosphate buffer solution (pH=6.0);

[0029] 2) Disperse the SBA-15 particles in the buffer solution prepared in step 1), soak for 48 hours to obtain a SBA-15 mesoporous silica / phosphate buffer solution dispersion with a mass fraction of 15%, and refrigerate to -5°C until use;

[0030] 3) Prepare cellulose solvent, pre-cool to -12°C, then add cellulose, stir to dissolve, defoam and remove impurities, and finally obtain a cellulose solution with a mass fraction of 4%;

[0031] 4) Add the pre-cooled mesoporous silica / buffer solution dispersion prepared in step 2) into the cellulose solution pre-cooled to -10°C, and stir mechanically for 2 minutes to obtain a SBA-15 particle mass fraction of 2%. Casting solution;

[0032] 5) Pour the casting liquid prepared in step 4) into the film-making template, use ...

Embodiment 2

[0036] A method for preparing a mesoporous silica and cellulose blend membrane protected by a buffer solution, the specific steps are as follows:

[0037] 1) Configure 0.2mol / L phosphate buffer solution (pH=6.0);

[0038]2) Disperse the SBA-15 particles in the buffer solution prepared in step 1), soak for 24 hours to obtain a SBA-15 mesoporous silica / phosphate buffer solution dispersion with a mass fraction of 10%, and refrigerate to -3°C until use;

[0039] 3) Prepare cellulose solvent, pre-cool to -12°C, then add cellulose, stir to dissolve, defoam and remove impurities, and finally obtain a cellulose solution with a mass fraction of 3.5%;

[0040] 4) Add the pre-cooled mesoporous silica / buffer solution dispersion prepared in step 2) into the cellulose solution pre-cooled to -10°C, and stir mechanically for 1 minute to obtain a SBA-15 particle mass fraction of 1%. Casting solution;

[0041] 5) Pour the casting liquid prepared in step 4) into the film-making template, use ...

Embodiment 3

[0045] A method for preparing a mesoporous silica and cellulose blend membrane protected by a buffer solution, the specific steps are as follows:

[0046] 1) Prepare 0.1mol / L citric acid-sodium citrate buffer solution (pH=6.4);

[0047] 2) Disperse the MCM-41 particles in the buffer solution prepared in step 1), soak for 72 hours to obtain the MCM-41 mesoporous silica / citric acid-sodium citrate buffer solution dispersion with a mass fraction of 5%, and refrigerate until -3°C for use;

[0048] 3) Prepare cellulose solvent, pre-cool to -12°C, then add cellulose, stir to dissolve, defoam and remove impurities, and finally obtain a cellulose solution with a mass fraction of 4%;

[0049] 4) Add the pre-cooled mesoporous silica / buffer solution dispersion prepared in step 2) into the cellulose solution pre-cooled to -10°C, and stir mechanically for 3 minutes to obtain MCM-41 particles with a mass fraction of 0.5%. Casting solution;

[0050] 5) Pour the casting solution prepared in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com