A kind of waterborne acrylic resin antistatic coating and preparation method thereof

A water-based acrylic and acrylic resin technology, which is applied in conductive coatings, fireproof coatings, polyurea/polyurethane coatings, etc., can solve problems such as unsatisfactory research results, immature theory of modified conductive fillers and polymers, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

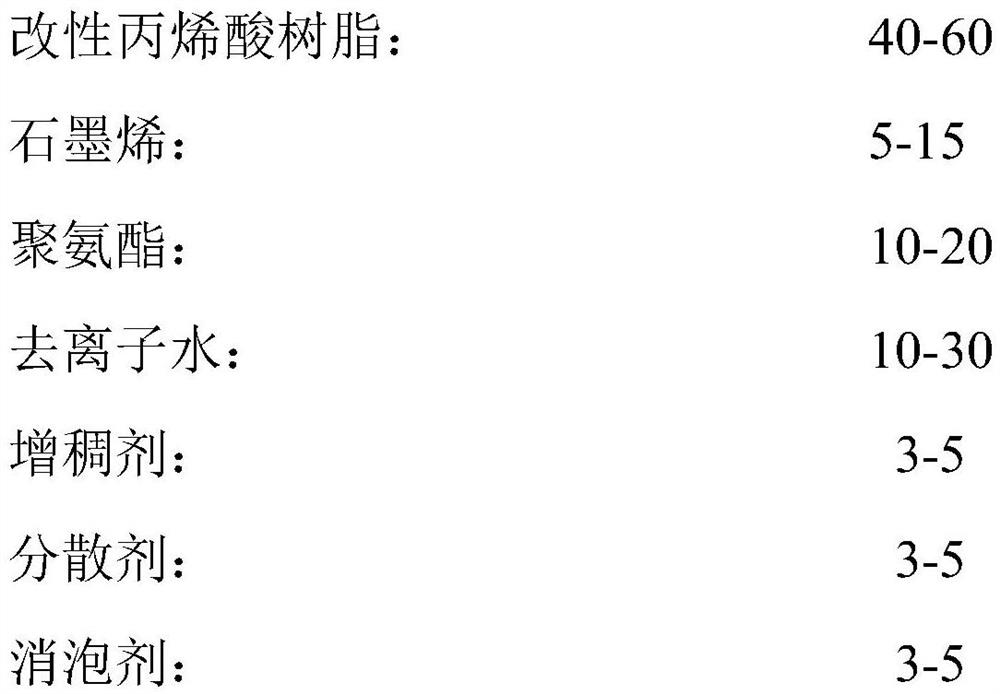

[0020] Present embodiment proposes a kind of waterborne acrylic resin antistatic coating, and described coating comprises following component by weight percentage:

[0021]

[0022] The modified acrylic resin is formed by reacting methacrylic acid, ethyl acrylate, butyl acrylate, n-butanol and modified substances under the action of an initiator. The modified substance is organosilicon and epoxy resin, the organosilicon is acryltrimethoxysilane, and the epoxy resin can be selected from E-51, E-44, E-20 and E-12. The initiator is azobisisobutyronitrile or benzoyl peroxide. In the present invention, the modified acrylic resin adopts a free radical polymerization mechanism. First, the α-H atom on the ortho-carbon of the acid bond in the epoxy resin and the H atom on the tertiary carbon atom are relatively active. Under the action, free radicals are formed, and monomer free radicals are also present at the same time; organosilicon monomers containing double bonds and acrylic a...

Embodiment 2

[0036] On the basis of embodiment 1, the present embodiment proposes a kind of waterborne acrylic resin antistatic coating, increases copper powder on the raw material component, and described coating comprises following component by weight percentage:

[0037]

[0038]

[0039] Present embodiment also provides a kind of preparation method of waterborne acrylic resin antistatic paint, comprises the following steps:

[0040] (1) each component is taken by weight, for subsequent use;

[0041] (2) Add deionized water, thickener, a little dispersant and defoamer to the prepared graphene, mix and stir, ultrasonicate for 1.5h at a power of 375W, and then centrifugally mix at 5500 rpm 55min, then continue to add dispersant, continue ultrasonication for 1.5h, centrifuge and mix for 55min, repeat 4-5 times to obtain a mixed dispersion.

[0042] (3) After the mixture obtained in step (2) is left to stand until the foam completely disappears, add modified acrylic resin and polyure...

Embodiment 3

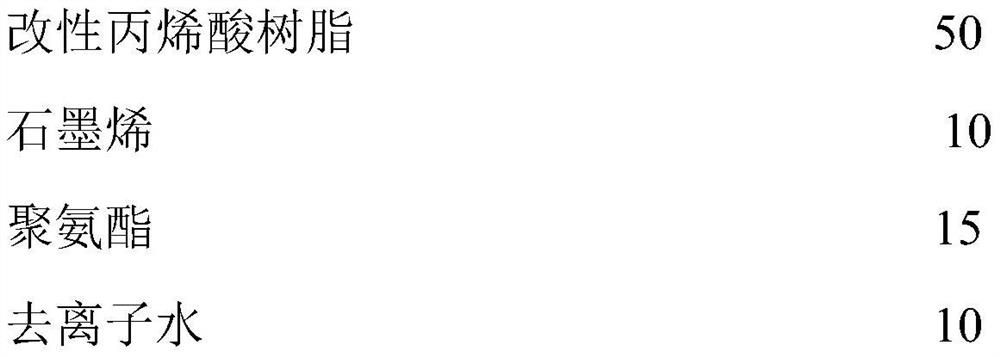

[0045] On the basis of embodiment 1, the present embodiment proposes a kind of waterborne acrylic resin antistatic coating, and described coating comprises following component by weight percentage:

[0046]

[0047]

[0048] Present embodiment also provides a kind of preparation method of waterborne acrylic resin antistatic paint, comprises the following steps:

[0049] (1) each component is taken by weight, for subsequent use;

[0050] (2) Add deionized water, thickener, a little dispersant and defoamer to the prepared graphene, mix and stir, ultrasonicate for 2h at a power of 350W, and then centrifuge and mix at 5000 rpm for 60min , and then continue to add the dispersant, continue to sonicate for 2h, centrifuge and mix for 60min, repeat 4-5 times to obtain a mixed dispersion.

[0051] (3) After the mixture obtained in step (2) is left to stand until the foam completely disappears, add modified acrylic resin and polyurethane to the mixed dispersion, heat to 70°C, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com