Process for producing lubricant base oil through hydrotreatment of heavy-duty bitumen distillate oil

A lubricating oil base oil and hydrotreating technology, which is applied in the field of lubricating oil base oil, can solve problems such as non-compliance with various indicators of lubricating oil base oil, poor quality of lubricating oil base oil, complex components of heavy traffic asphalt distillate oil, etc. , to achieve the effect of ensuring the overall rationality, reducing energy consumption, and reasonable route design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

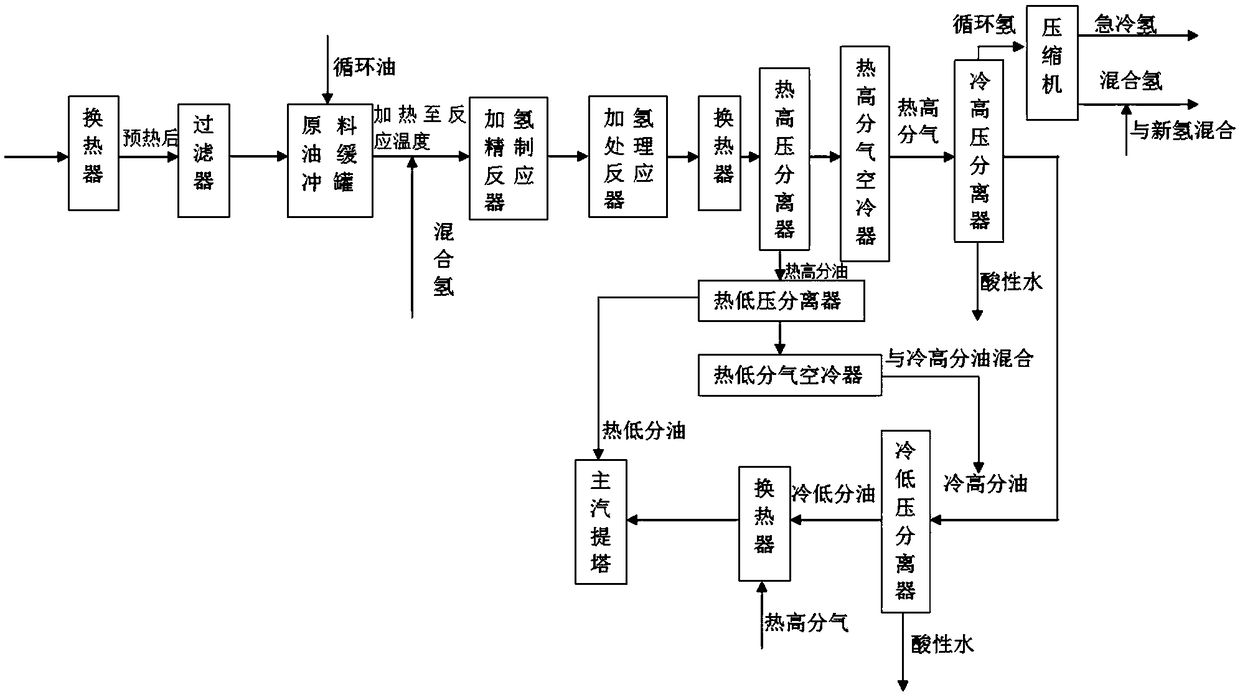

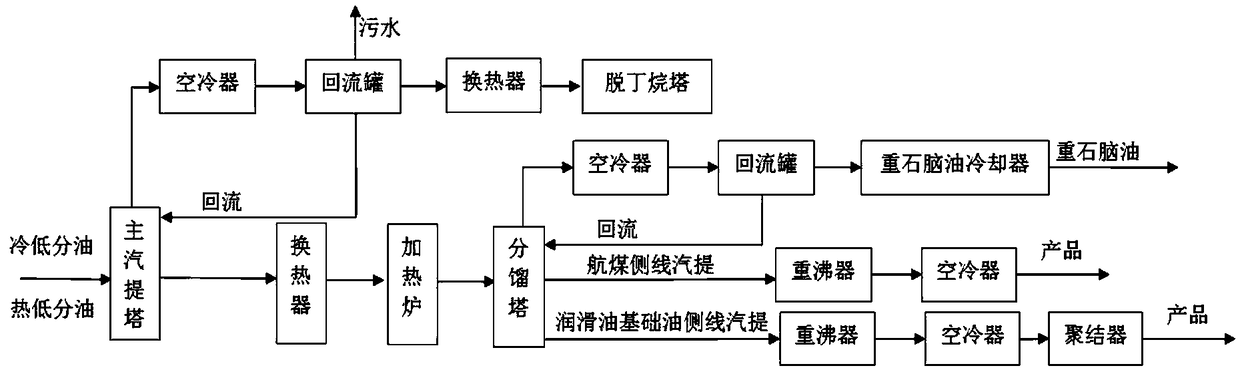

[0038] The process of hydrotreating heavy traffic asphalt distillate oil to produce lubricating oil base oil includes the following two parts:

[0039] (1) Hydrogenation reaction part:

[0040] ① Send the heavy traffic asphalt distillate oil from the device into the device, exchange heat with the lubricating base oil to raise the temperature, enter the filter to remove particles larger than 25 microns, and then mix with the circulating oil from the fractionation part to enter the raw material protected by inert gas The oil buffer tank forms raw oil;

[0041] ②The raw oil in the raw oil buffer tank exchanges heat with the reaction effluent from the hydrotreating reactor, mixes with mixed hydrogen, enters the hydrofinishing reactor for hydrofining reaction, and then enters the hydrotreating reactor for hydrogenation For hydrogen treatment reaction, quenching hydrogen injection facilities are installed between the beds of the reactor and between the reactors;

[0042] ③ After t...

Embodiment 2

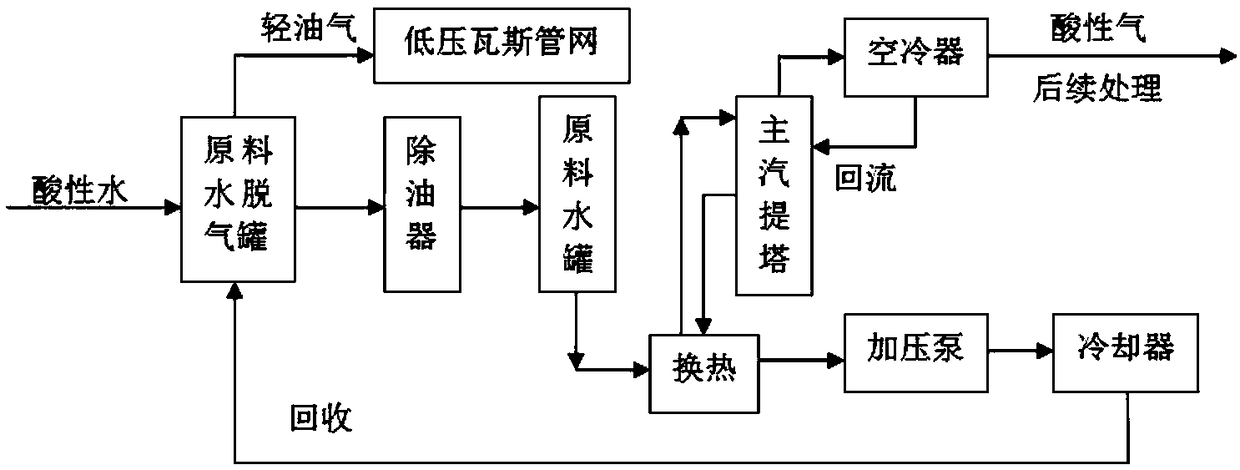

[0062] The sour water stripping process is as follows:

[0063] ①Acidic water enters the raw water degassing tank, and the degassed light oil gas is sent to the low-pressure gas pipe network; the degassed acidic water enters the degreaser to settle and remove oil, and the degassed light dirty oil flows intermittently to the dirty oil tank, and is pressurized Sent to the waste oil tank area of the factory; the acidic water after oil removal enters the raw water tank to form raw water, pressurized by the raw water feed pump, exchanges heat with the purified water at the bottom of the main stripper to 100°C, and enters the main stripper upper part;

[0064] ② After heat exchange between the purified water at the bottom of the main stripper and the raw water, it is pressurized by the purified water booster pump, cooled to 35°C by the purified water cooler, and sent to the raw water degassing tank for reuse;

[0065] ③ After the acid gas at the top of the main stripping tower is...

Embodiment 3

[0074] The sour water stripping process is as follows:

[0075] ①Acidic water enters the raw water degassing tank, and the degassed light oil gas is sent to the low-pressure gas pipe network; the degassed acidic water enters the degreaser to settle and remove oil, and the degassed light dirty oil flows intermittently to the dirty oil tank, and is pressurized Sent to the waste oil tank area of the factory; the acidic water after oil removal enters the raw water tank to form raw water, pressurized by the raw water feed pump, exchanges heat with the purified water at the bottom of the main stripper to 105°C, and enters the main stripper upper part;

[0076] ② After heat exchange between the purified water at the bottom of the main stripper and the raw water, it is pressurized by the purified water booster pump, cooled to 30°C by the purified water cooler, and sent to the raw water degassing tank for reuse;

[0077] ③ After the acid gas at the top of the main stripping tower is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com