Liquid nattokinase fermentation method

A technology of nattokinase and production method, which is applied in the field of food processing and can solve the problems of no economic benefit and high energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Embodiment 1 The preparation of nattokinase crude enzyme liquid

[0029] 1. Preparation of starter

[0030] Buy Bacillus natto powder, dissolve it with sterile water, and dilute it to 10 -3 to 10 -6 Different gradient plates were streaked and cultured on LB medium containing 2% agar for 18 hours for microscopic examination. figure 1 , and then pick a single colony into LB liquid medium, activate three generations, then inoculate 3% inoculum in LB liquid medium at 120rpm, and cultivate at 37°C for 12h; the bacterial liquid is placed in a high-speed refrigerated centrifuge at 4°C, 9500r / min centrifuged for 10min; the centrifuged cells were washed twice with sterile water, resuspended, and the concentration of the bacterial suspension was adjusted to 10 7 CFU / mL, as starter culture.

[0031] 2. Preparation of fermentation medium

[0032] At room temperature, soak soybeans at a mass ratio of 1:5 to water for 13 hours, drain the water, grind the soaked soybeans with wa...

Embodiment 2

[0035] Embodiment 2 nattokinase liquid fermentation process optimization

[0036] 1. Optimization of fermentation conditions of nattokinase

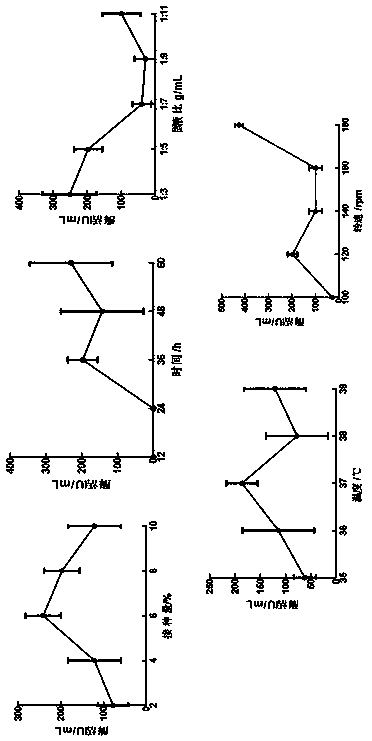

[0037] Investigate the influence of the five factors of inoculum size, fermentation temperature, fermentation time, shaker speed, and solid-liquid ratio on the activity of nattokinase, and obtain the parameter range of the optimal enzyme activity of nattokinase as follows: figure 2 , and according to the Box–Behnken principle on the basis of the single factor test, the fermentation time, the rotating speed of the shaking table, and the three main factors of the inoculum amount are carried out in a response surface test design. The test factor level table is shown in Table 1, and the test results are shown in Table 2;

[0038] Through the single factor test, it can be determined that the enzyme activity reaches the highest at 37°C, which is related to the influence of temperature on the metabolism of the bacteria. When the temperature is...

Embodiment 3

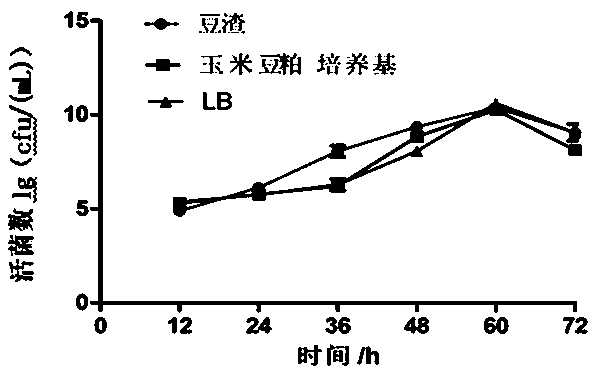

[0050] Embodiment 3 Enzyme production comparison and live bacteria count of different fermentation media

[0051] Investigate the impact of the type of medium on the activity of nattokinase, the specific operation steps are as follows:

[0052] will reach 10 7 Bacillus natto starter culture with cfu / mL number of live bacteria was respectively inserted into soybean dregs medium, corn soybean meal medium, and LB medium with the same inoculum amount, and cultured in a shaker at the same temperature and at the same speed, and then each time Take the three kinds of liquid culture medium by centrifugation every 12 hours and take the supernatant to measure the activity of nattokinase. At the same time, take part of the supernatant for 10-fold gradient serial dilution, and select 2~3 suitable gradients to spread evenly on the plate. Three parallel experiments were carried out for each gradient and the average value was used to count the viable colonies; the results of nattokinase act...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com