Temperature rising and falling type sound velocity measuring instrument

A measuring instrument and heating and cooling technology, applied in the direction of measuring device, measuring propagation velocity, measuring ultrasonic/sonic wave/infrasonic wave, etc., can solve problems such as easy formation of echo, increased error rate, temperature control lag, etc., to improve accuracy and reduce Reading error rate, the effect of avoiding reading errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

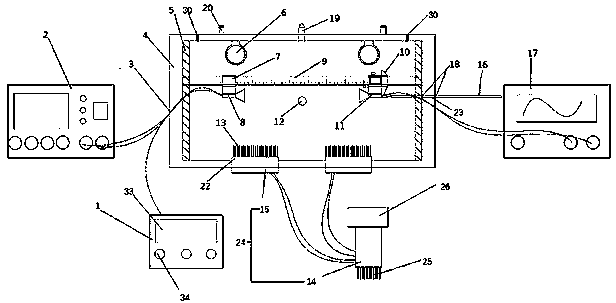

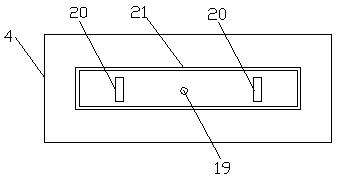

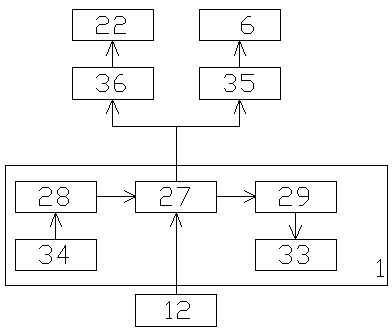

[0037] In order to make the technical solution of the present invention clearer, the present invention will be further described below in conjunction with the accompanying drawings. Any solution obtained by equivalent replacement and conventional reasoning of the technical features of the technical solution of the present invention falls within the protection scope of the present invention. The fixed connection method and fixed arrangement method not mentioned in this embodiment are one of glue, bolt and nut connection, and screw connection. The wires of the ultrasonic generating transducer and ultrasonic receiving transducer inside the plexiglass box are connected to the control panel, signal generator, and oscilloscope through wire holes. Wired to connect to the control panel.

[0038]The signal generator, the ultrasonic generation transducer and the ultrasonic receiving transducer used in this embodiment are a set of existing instruments, which are the SV-DH series sound ve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com