Persistent plant essential oil sustained-release capsules for cosmetics and preparation method

A technology of plant essential oils and slow-release capsules, which is applied in cosmetic preparations, cosmetics, dressing preparations, etc. It can solve the problems of essential oil preservation and utilization, the complexity of plant essential oil capsules, and the volatilization of plant essential oils, etc., to achieve excellent adhesion Sexuality, complete coating stability, good hydrophilicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

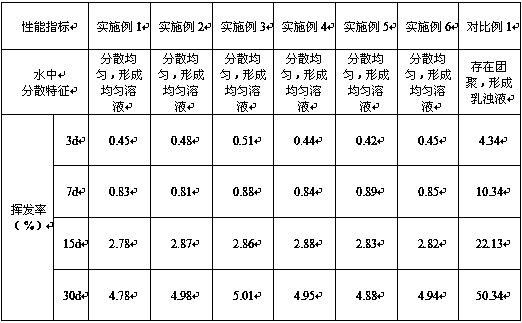

Examples

Embodiment 1

[0032] The preparation process is:

[0033] (1) Mix plant essential oils, emulsifiers, and gelatin solutions and place them in a high-speed homogenizer, then perform high-speed homogenization and emulsification at a speed of 1100r / min in an ice bath for 27 minutes to obtain emulsified plant essential oils as material A; The plant essential oil is rose essential oil; the emulsifier is sulfosuccinate; the gelatin solution is an aqueous solution prepared from skin gelatin, and the mass concentration is 8%; in material A, 72 parts by weight of plant essential oil, 3 parts by weight of emulsifier, and 23 parts by weight of gelatin solution share;

[0034] (2) Add perhydropolysilazane into the solvent, mix evenly, and obtain a solution as material B; the solvent is toluene; in material B, there are 30 parts by weight of perhydropolysilazane and 70 parts by weight of solvent;

[0035] (3) Put the material A prepared in step (1) and the material B prepared in step (2) into the atomiz...

Embodiment 2

[0041] The preparation process is:

[0042] (1) Mix the plant essential oil, emulsifier, and gelatin solution and place them in a high-speed homogenizer, then perform high-speed homogenization and emulsification at a speed of 1400r / min in an ice bath for 22 minutes to obtain emulsified plant essential oils as material A; The plant essential oil is Perrin essential oil; the emulsifier is ether sulfosuccinate; the gelatin solution is an aqueous solution prepared from bone gelatin, and the mass concentration is 13%; in material A, 62 parts by weight of plant essential oil, 4 parts by weight of emulsifier, and 34 parts by weight of gelatin solution parts by weight;

[0043] (2) Add perhydropolysilazane into the solvent, mix evenly, and obtain a solution as material B; the solvent is xylene; in material B, there are 40 parts by weight of perhydropolysilazane and 60 parts by weight of solvent;

[0044] (3) Put the A material obtained in step (1) and the B material obtained in step ...

Embodiment 3

[0050] The preparation process is:

[0051] (1) Mix the plant essential oil, emulsifier, and gelatin solution and place them in a high-speed homogenizer, then perform high-speed homogenization and emulsification at a speed of 1300r / min in an ice bath for 26 minutes to obtain emulsified plant essential oils as material A; The plant essential oil is quince essential oil; the emulsifier is sulfosuccinamate; the gelatin solution is an aqueous solution prepared from sarcolemmal gelatin, and the mass concentration is 9%; in material A, 68 parts by weight of plant essential oil, 3 parts by weight of emulsifier, gelatin Liquid 29 parts by weight;

[0052] (2) Add perhydropolysilazane into the solvent, mix evenly, and obtain a solution as material B; the solvent is ethanol; in material B, there are 38 parts by weight of perhydropolysilazane and 62 parts by weight of solvent;

[0053] (3) Put the material A prepared in step (1) and the material B prepared in step (2) into the atomizer ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com