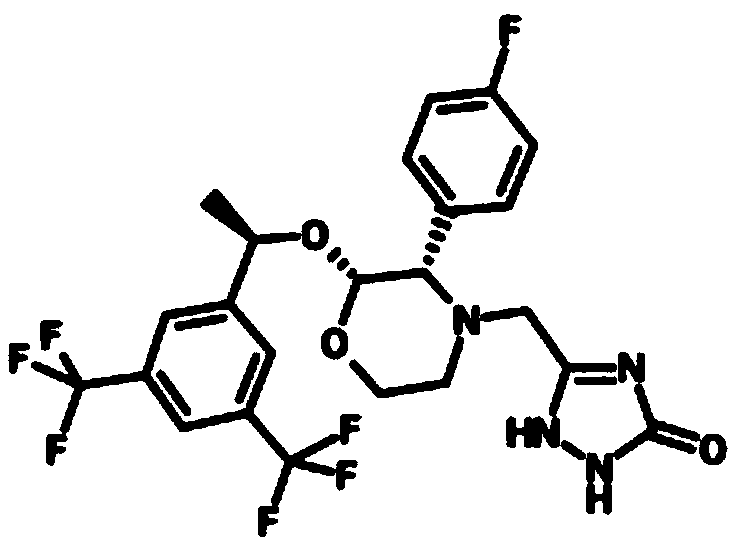

Aprepitant emulsion formulationpreparation and preparation method thereof

A technology for aprepitant and emulsion preparation, which is applied in the field of preparation of aprepitant injection emulsion, can solve the problems of poor preparation effect, poor preparation efficiency, poor stability, etc. Efficient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

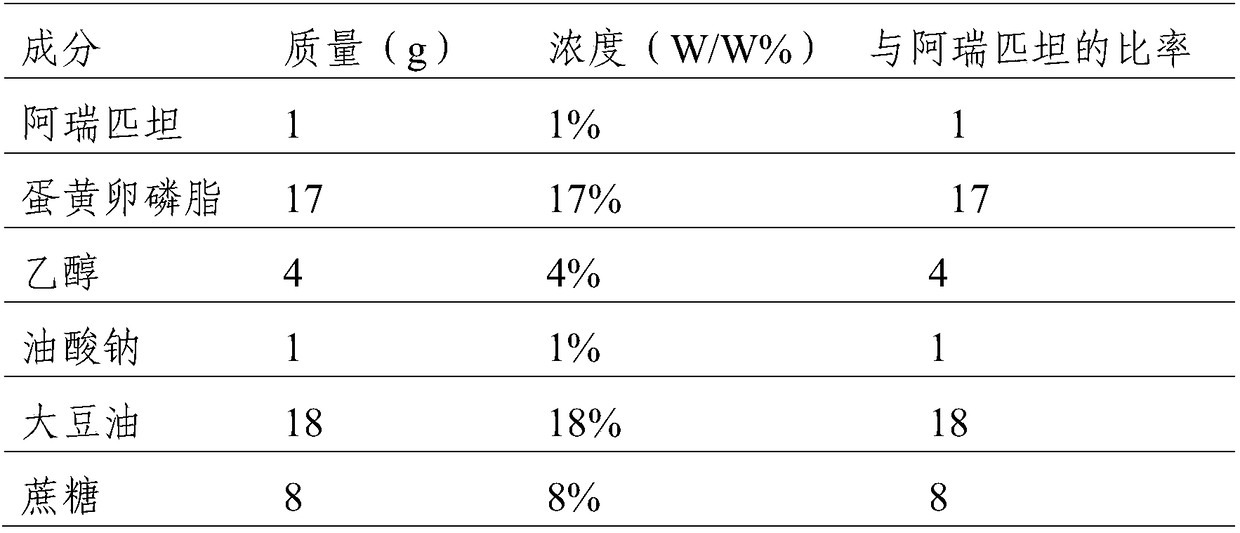

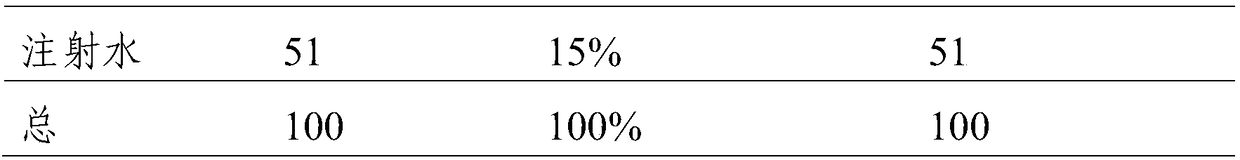

Embodiment 1

[0026] The preparation method of the aprepitant milk preparation of the embodiment of the present invention comprises the following steps:

[0027] Firstly, after mixing 1 g of aprepitant, 17 g of egg yolk lecithin, 4 g of ethanol, 1 g of sodium oleate and 18 g of soybean oil, they were stirred together. During the stirring process, the heating temperature of the mixture was controlled between 70°C and 80°C.

[0028] Then, dissolve 8 g of sucrose in 51 g of water for injection, keep the injection temperature between 40°C and 60° C., stir and dissolve continuously to form a water phase.

[0029]

[0030]

[0031] The oil phase formed above is added to the water phase. During the process of adding the oil phase to the water phase, the mixture needs to be stirred at a high speed of 12000r / min to 18000r / min to prepare the colostrum mixture. Then, use a high-pressure microjet 10000psi ~30000psi high-pressure homogenization of the colostrum mixture, repeated 11 times, to form ...

Embodiment 2

[0033] The preparation method of the aprepitant milk preparation of the embodiment of the present invention comprises the following steps:

[0034] First, mix 0.5g of aprepitant, 5g of egg yolk lecithin, 0.5g of ethanol, 1g of sodium oleate and 18g of soybean oil, and stir together. During the stirring process, the heating temperature of the mixture is controlled between 70°C and 80°C .

[0035] Then, dissolve 8 g of sucrose in 51 g of water for injection, keep the injection temperature between 40°C and 60° C., stir and dissolve continuously to form a water phase.

[0036] The oil phase formed above is added to the water phase. During the process of adding the oil phase to the water phase, the mixture needs to be stirred at a high speed of 15000r / min to prepare the colostrum mixture. Then, the colostrum mixture is treated with a high-pressure micro jet of 15000psi Carry out high-pressure homogenization and repeat 10 times to form aprepitant milk preparation, which is sterile ...

Embodiment 3

[0038] The preparation method of the aprepitant milk preparation of the embodiment of the present invention comprises the following steps:

[0039] Firstly, after mixing 1.5 g of aprepitant, 20 g of egg yolk lecithin, 5 g of ethanol, 2 g of sodium oleate and 20 g of soybean oil, they are stirred together. During the stirring process, the heating temperature of the mixture is controlled between 70° C. and 80° C.

[0040] Then, dissolve 10 g of sucrose in 41.5 g of water for injection, keep the injection temperature between 40°C and 60° C., and stir continuously to dissolve to form an aqueous phase.

[0041] The oil phase formed above is added to the water phase. During the process of adding the oil phase to the water phase, the mixture needs to be stirred at a high speed of 15000r / min to prepare the colostrum mixture. Then, the colostrum mixture is treated with a high-pressure micro jet of 30000psi Carry out high-pressure homogenization and repeat 9 times to form aprepitant mil...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com