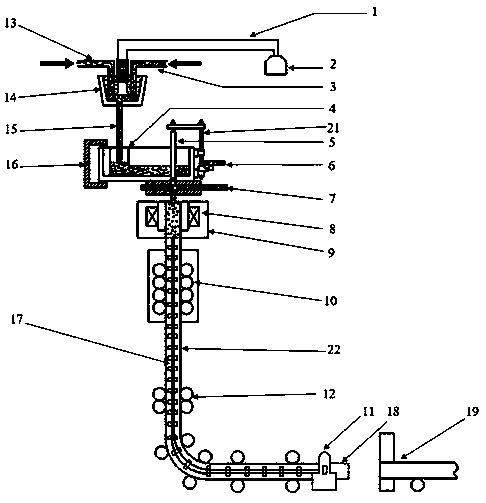

Continuous casting forming device and method for ceramic particle reinforced metal matrix composites

A technology of ceramic particles and composite materials, which is applied in the direction of metal processing equipment, casting equipment, casting melt containers, etc., can solve the problem of uniform distribution of ceramic hard particles, time-consuming and high process stability requirements, material structure and Uneven mechanical properties and other problems, to achieve the effects of large-scale production and continuous production, improve production economic benefits, and save production time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

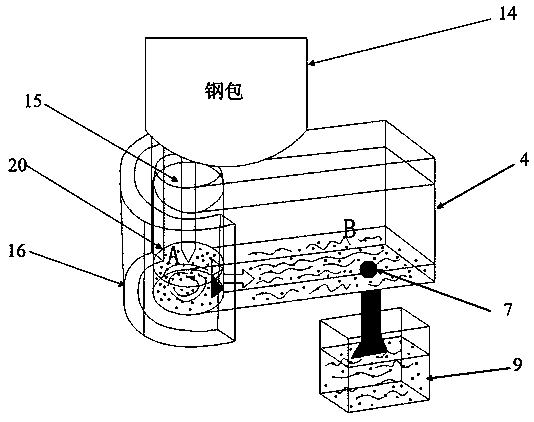

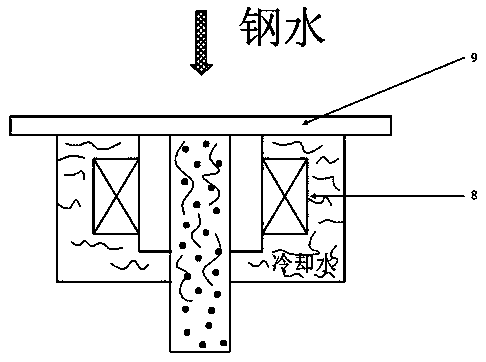

[0036] (1) Before feeding the mixing bag 14, turn on the igniter at the port 1 of the fuel delivery pipe, use the internal pressure device of the fuel storage tank 2 to inject fuel to the port 1 of the fuel delivery pipe, and dry and preheat the mixing bag 14, The front end of the fuel delivery pipe 1 is a telescopic delivery pipe. The height of the flame can be controlled by extending or shrinking the length of the delivery pipe. The temperature of the injection flame is 1200°C. The flame continuously sprays and heats the mixing bag for 60 minutes until the temperature of the inner wall of the mixing bag reaches 1100°C After shrinking the fuel delivery pipe 1 to the outside of the mixing bag 14, add 20-mesh alumina ceramic particles into the mixing bag 14 through the ceramic particle feeding pipe 3, dry it for 5 minutes by the heat in the mixing bag, and then feed it through molten steel Pipe 13 is quickly filled with molten steel, and the tapping temperature is set at 1700°C;...

Embodiment 2

[0047] (1) Before feeding the mixing bag 14, turn on the igniter at the port 1 of the fuel delivery pipe, use the internal pressure device of the fuel storage tank 2 to inject fuel to the port 1 of the fuel delivery pipe, and dry and preheat the mixing bag 14, The front end of the fuel delivery pipe 1 is a telescopic delivery pipe. The height of the flame can be controlled by extending or shrinking the length of the delivery pipe. The temperature of the injection flame is 1300°C. The flame continuously sprays and heats the mixing bag for 50 minutes until the temperature of the inner wall of the mixing bag reaches 1200°C After shrinking the fuel delivery pipe 1 to the outside of the mixing bag 14, add 16-mesh boron carbide ceramic particles into the mixing bag 14 through the ceramic particle feeding pipe 3, and then transfer the material through the molten steel after drying by the heat in the mixing bag for 5 minutes Pipe 13 is quickly filled with molten steel, and the tapping ...

Embodiment 3

[0058] (1) Before feeding the mixing bag 14, turn on the igniter at the port 1 of the fuel delivery pipe, use the internal pressure device of the fuel storage tank 2 to inject fuel to the port 1 of the fuel delivery pipe, and dry and preheat the mixing bag 14, The front end of the fuel delivery pipe 1 is a telescopic delivery pipe. The height of the flame can be controlled by extending or shrinking the length of the delivery pipe. The temperature of the injection flame is 1400°C. The flame continuously sprays and heats the mixing bag for 60 minutes, until the temperature of the inner wall of the mixing bag reaches 1100°C After shrinking the fuel delivery pipe 1 to the outside of the mixing bag 14, add 30-mesh zirconium corundum ceramic particles into the mixing bag 14 through the ceramic particle feeding pipe 3, dry the heat in the mixing bag for 5 minutes, and then transfer the material through molten steel Pipe 13 is quickly filled with molten steel, and the tapping temperatu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com