Preparation process for ammonium paratungstate

An ammonium paratungstate and preparation process technology, applied in the field of chemistry, can solve the problems of high product quality and reaction energy consumption, low purity of ammonium paratungstate, and many impurities in ammonium paratungstate, and achieve the effects of easy reaction, reduced production energy consumption and low reaction conditions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

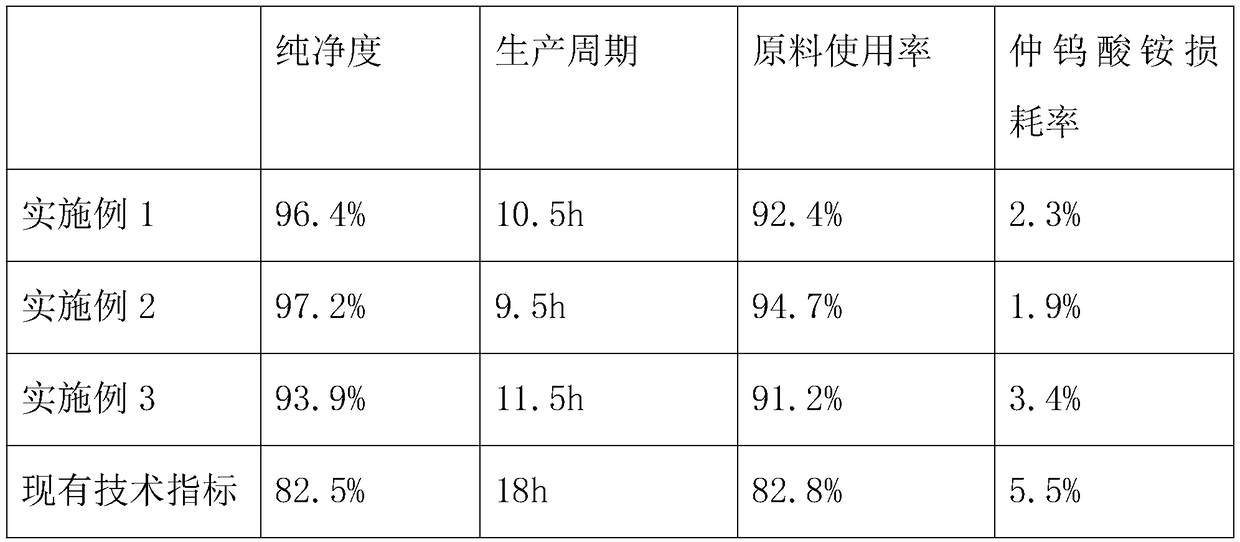

Examples

Embodiment 1

[0021] A kind of preparation technology of ammonium paratungstate, its technological process comprises:

[0022] (1) Preparation of sodium tungstate: use tungsten trioxide as the anode electrode, and graphene-modified carbon rod as the cathode electrode to catalyze the preparation of sodium tungstate into sodium tungstate. The specific process is as follows:

[0023] a Removal of impurities: Grind the raw tungsten block to 2400 mesh, put it in the mixing bucket and add concentrated H2SO4 gradient stirring. The gradient stirring procedure includes ordinary stirring at a speed of 800r / min for 8 minutes, and medium speed stirring at a speed of 1200r / min Stir for 15 minutes, stir at a high speed of 2000r / min for 10 minutes, use tungsten trioxide as the anode electrode, and use graphene-modified carbon rods as the cathode electrode to energize and catalyze the reaction, let it stand for 80 minutes, filter out dissolved impurities, and prepare the tungstic acid solution spare;

[0...

Embodiment 2

[0034] A kind of preparation technology of ammonium paratungstate, its technological process comprises:

[0035] (1) Preparation of sodium tungstate: use tungsten trioxide as the anode electrode, and graphene-modified carbon rod as the cathode electrode to catalyze the preparation of sodium tungstate into sodium tungstate. The specific process is as follows:

[0036] a Removal of impurities: Grind the raw tungsten block to 2400 mesh, put it in the mixing bucket and add concentrated H2SO4 gradient stirring. The gradient stirring procedure includes ordinary stirring at a speed of 800r / min for 8 minutes, and medium speed stirring at a speed of 1200r / min Stir for 15 minutes, stir at a high speed of 2000r / min for 10 minutes, use tungsten trioxide as the anode electrode, and use graphene-modified carbon rods as the cathode electrode to energize and catalyze the reaction, let it stand for 80 minutes, filter out dissolved impurities, and prepare the tungstic acid solution spare;

[0...

Embodiment 3

[0047] A kind of preparation technology of ammonium paratungstate, its technological process comprises:

[0048] (1) Preparation of sodium tungstate: use tungsten trioxide as the anode electrode, and graphene-modified carbon rod as the cathode electrode to catalyze the preparation of sodium tungstate into sodium tungstate. The specific process is as follows:

[0049] a Removal of impurities: Grind the raw tungsten block to 2400 mesh, put it in the mixing bucket and add concentrated H2SO4 gradient stirring. The gradient stirring procedure includes ordinary stirring at a speed of 800r / min for 8 minutes, and medium speed stirring at a speed of 1200r / min Stir for 15 minutes, stir at a high speed of 2000r / min for 10 minutes, use tungsten trioxide as the anode electrode, and use graphene-modified carbon rods as the cathode electrode to energize and catalyze the reaction, let it stand for 80 minutes, filter out dissolved impurities, and prepare the tungstic acid solution spare;

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com