Composite cement-based adsorption material and preparation method thereof

An adsorption material and composite cement technology, applied in chemical instruments and methods, adsorption water/sewage treatment, water/sludge/sewage treatment, etc., to achieve the effects of fast adsorption rate, improved adsorption efficiency, and improved adsorption rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

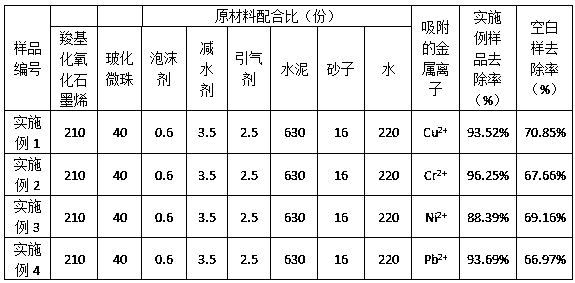

Embodiment 1

[0036] A composite cement-based adsorption material operates according to the following steps:

[0037] 1) Ingredients: Carboxylated graphene oxide, vitrified microbeads, sodium dodecylbenzenesulfonate foaming agent, polycarboxylate water reducer, rosin air-entraining agent, cement, sand and water according to the weight ratio = 210:40:0.6:3.5:2.5:630:16:220 Accurately weigh and place in categories.

[0038] 2) Dispersion: adding carboxylated graphene oxide into water, and ultrasonically treating it for 30 minutes to obtain a carboxylated graphene oxide dispersion.

[0039] 3) Inhalation: immerse the vitrified microbeads in the carboxylated graphene oxide dispersion for 3 hours, stir at a constant speed for 50 seconds, and steam them in a steam room at 90°C for 2 hours. Immerse in the carboxylated graphene oxide dispersion for the first time for 3 hours, stir at a constant speed for 60 seconds, steam in a steam curing room at 90°C for 2 hours, and then place the vitrified mic...

Embodiment 2

[0046] A composite cement-based adsorption material operates according to the following steps:

[0047] 1) Ingredients: Carboxylated graphene oxide, vitrified microbeads, fatty alcohol polyoxyethylene ether sodium sulfate foaming agent, polycarboxylate water reducer, saponin air-entraining agent, cement, sand and water according to the weight ratio =200:60:0.5:5:3:600:10:200 Accurately weigh, classify and place.

[0048] 2) Dispersion: adding carboxylated graphene oxide into water, and ultrasonically treating it for 40 minutes to obtain a carboxylated graphene oxide dispersion.

[0049] 3) Inhalation: Immerse the vitrified microbeads in the carboxylated graphene oxide dispersion for 5 hours, stir at a constant speed for 30 seconds, and steam them in a steam room at 80°C for 3 hours, and put the steamed vitrified microbeads for a second time. Immerse in the carboxylated graphene oxide dispersion for the first time for 5 hours, stir at a constant speed for 30 seconds, steam in ...

Embodiment 3

[0056] A composite cement-based adsorption material operates according to the following steps:

[0057] 1) Ingredients: Carboxylated graphene oxide, vitrified microbeads, sodium lauryl sulfate foaming agent, polycarboxylate water reducer, rosin air-entraining agent, cement, sand and water according to the weight ratio = 240: 30:0.8:3:2:650:18:230 Accurately weigh and place in categories.

[0058] 2) Dispersion: adding carboxylated graphene oxide into water, and ultrasonically treating it for 35 minutes to obtain a carboxylated graphene oxide dispersion.

[0059] 3) Inhalation: immerse the vitrified microbeads in the carboxylated graphene oxide dispersion for 4 hours, stir at a constant speed for 40 seconds, and steam for 2.5 hours in a steam-curing room at 85°C. Immerse in the carboxylated graphene oxide dispersion for the first time for 4 hours, stir at a constant speed for 30 seconds, steam in a steam curing room at 90°C for 3 hours, and then place the vitrified microbeads ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Strength | aaaaa | aaaaa |

| Strength | aaaaa | aaaaa |

| Strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com