Method for preparing elemental oxygen-resistant polyimide material by in-situ hydrolysis method

An oxygen polyimide film and polyimide technology are applied in the field of preparing atomic oxygen-resistant polyimide materials by an in-situ hydrolysis method, achieving the effects of easy conditions, wide application range and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

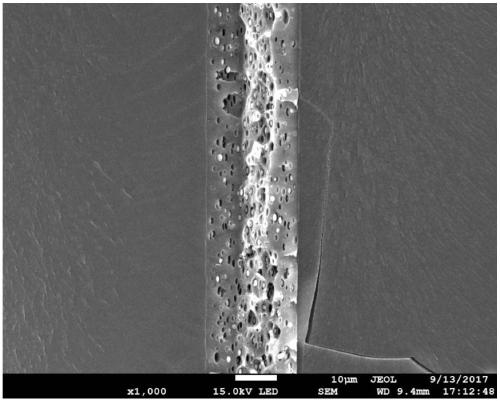

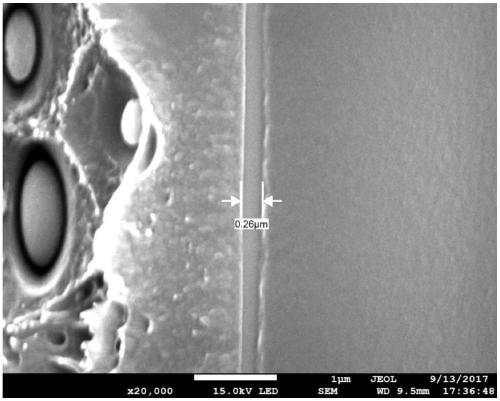

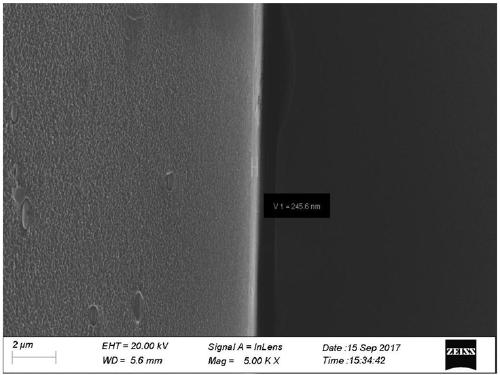

[0028]The atomic oxygen resistant polyimide film material of PMDA / ODA system was prepared. (1) Weigh 2.0g of pyromellitic dianhydride (PMDA) and 1.8g of 4,4'-diaminodiphenyl ether (ODA) with a molar ratio of 1:1, and dissolve all ODA in 30ml of N,N - Dimethylformamide (DMF) solvent, mechanical stirring, after ODA is completely dissolved in DMF, under the condition of ice-water bath, add PMDA step by step, after obtaining the polyamic acid (PAA) solution with moderate viscosity, mechanical stirring 2h Finally, add 40wt% tetraethyl orthosilicate (TEOS) based on the weight of the polyamic acid by dropping, and stir to obtain a uniform mixed solution; The compound solution was made into a thin film, and placed at room temperature for 24 hours; (3) the polyamic acid film was placed in a hot furnace, and the temperature was gradually raised to 300 ° C at a heating rate of 5 ° C / min, and kept for 0.5 h; (4) The polyamic acid film is placed in the airtight container that contains a...

Embodiment 2

[0030] The atomic oxygen resistant polyimide film material of PMDA / ODA system was prepared. (1) Weigh 2.0g of pyromellitic dianhydride (PMDA) and 1.8g of 4,4'-diaminodiphenyl ether (ODA) with a molar ratio of 1:1, and dissolve all ODA in 30ml of N,N - Dimethylformamide (DMF) solvent, mechanical stirring, after ODA is completely dissolved in DMF, under the condition of ice-water bath, add PMDA step by step, after obtaining the polyamic acid (PAA) solution with moderate viscosity, mechanical stirring 2h Finally, add tetraethyl orthosilicate (TEOS) based on 60wt% of the polyamic acid weight by dropping, and stir to obtain a uniform mixed solution; (2) adopt the above-mentioned polyamic acid / silicon The compound solution was made into a thin film, and placed at room temperature for 12 hours; (3) the polyamic acid film was placed in a hot furnace, and the temperature was gradually raised to 300 ° C at a heating rate of 3 ° C / min, and kept for 1 h; (4) the The polyamic acid film ...

Embodiment 3

[0032] The atomic oxygen resistant polyimide film material of BPDA / PDA system was prepared. (1) Weigh 2.82g of 3,3'4,4'-biphenyltetracarboxylic dianhydride (BPDA) and 1.02g of p-phenylenediamine (PDA) with a molar ratio of 1:1, and dissolve all the PDA in 30ml of N, N-dimethylacetamide (DMAc) solvent, mechanical stirring, after PDA is all dissolved in DMAc, under the condition of ice-water bath, add BPDA step by step, after obtaining the polyamic acid (PAA) solution with moderate viscosity, After mechanical stirring for 2 hours, add 40wt% tetraethyl orthosilicate (TEOS) based on the weight of polyamic acid by dropwise addition, and stir to obtain a uniform mixed solution; The acid / silicon compound solution was used to form a thin film, and placed at room temperature for 12 hours; (3) the polyamic acid film was placed in a heating furnace, and the temperature was gradually raised to 300°C at a heating rate of 5°C / min, and kept for 0.5h; (4) The polyamic acid film is hydrolyzed...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com