Surface modification method of axles of high-speed trains

A high-speed EMU and surface modification technology, applied in furnace types, furnaces, heat treatment furnaces, etc., can solve the problem of inability to achieve local treatment, and achieve the effect of improving hardness, improving service life, and improving hardness and wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

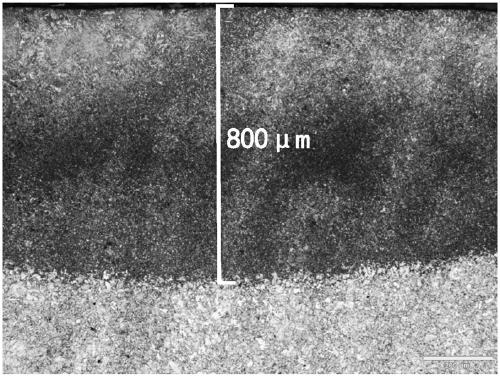

[0038] In this embodiment, the preparation process of the axle with a quenching depth of 800 μm:

[0039] 1) The surface of the high-speed EMU axle is finished, and the surface roughness of the laser quenching part is Ra0.8; the workbench is used to clamp the variable gauge axle, and the surface is sprayed with SiO 2 Light absorbing layer, SiO 2 The composition of the light-absorbing layer is: by weight percentage, 57% of silicon dioxide, 15% of aluminum oxide, 10% of montmorillonite, 6.5% of cerium oxide, and the rest is shellac resin, which is dried and SiO 2 The thickness of the light absorbing layer was 15 μm.

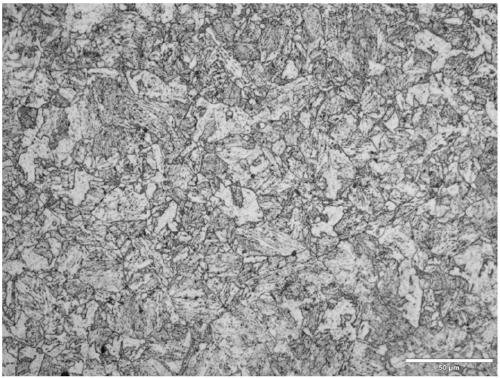

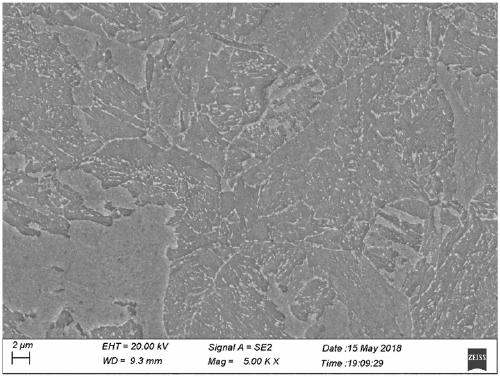

[0040] 2) Adjust the angle between the laser head and the surface of the axle at 90°, set the laser output power to 1200W, the spot diameter to 4mm, the spot scanning rate to 20mm / s, the spot spacing to 2.5mm, and the spot height to 70mm to perform laser quenching on the axle surface. The argon gas is blown to the laser heating area, and the cooling rate is contr...

Embodiment 2

[0044] In this embodiment, the preparation process of the axle with a quenching depth of 350 μm:

[0045] 1) The surface of the axle of the high-speed EMU is finished, and the surface roughness Ra of the laser quenching part reaches 0.4μm; the variable gauge axle is clamped by the workbench, and the surface is sprayed with SiO 2 Light absorbing layer, SiO 2 The composition of the light-absorbing layer is: by weight percentage, 57% of silicon dioxide, 15% of aluminum oxide, 10% of montmorillonite, 6.5% of cerium oxide, and the rest is shellac resin, which is dried and SiO 2 The thickness of the light absorbing layer was 20 μm.

[0046] 2) Adjust the 90° angle between the laser head and the surface of the axle, set the laser output power to 1800W, the spot diameter to 4mm, the spot scanning rate to 50mm / s, the spot spacing to 3mm, and the spot height to 70mm, perform laser quenching on the axle surface, and argon The gas is blown to the laser heating area, and the cooling rate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface roughness | aaaaa | aaaaa |

| Surface roughness | aaaaa | aaaaa |

| Depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com