Method for preparing DLC protective coating on surface of magnesium alloy

A technology of protective coating and magnesium alloy, which is applied in the direction of metal material coating process, coating, gaseous chemical plating, etc., can solve the problems of poor corrosion resistance and low strength, and achieve improved service life, low cost, and easy handling The effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

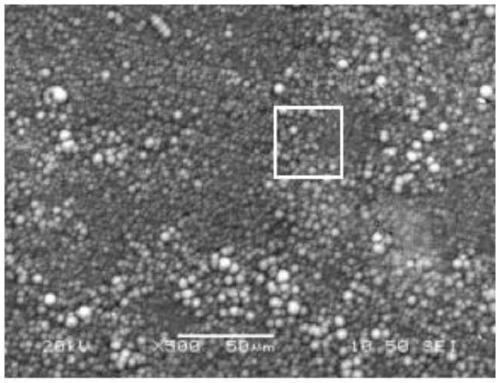

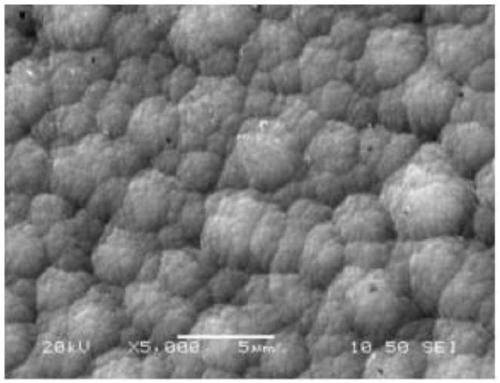

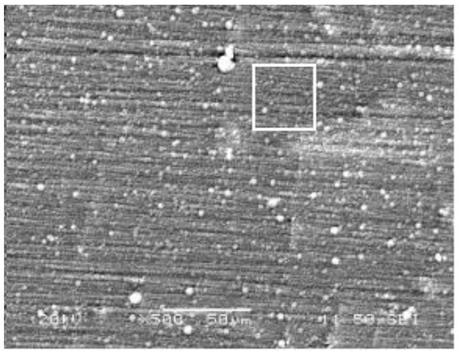

[0034] Embodiment one: the preparation method of DLC protective coating on the surface of magnesium alloy is to carry out according to the following steps:

[0035] 1. Magnesium alloy surface roughening treatment: Use sandpaper to treat the surface of the magnesium alloy sample, ultrasonically clean it, and dry it to obtain the sample to be etched. The sample to be etched is immersed in a 0.1mol / L nitric acid solution at room temperature. Etching treatment, and then ultrasonic cleaning in absolute ethanol solution to remove residual reaction products on the surface, and drying to obtain the sample to be sputtered;

[0036] 2. Sputtering cleaning: Put the sample to be sputtered into the vacuum chamber, vacuumize, and wait for the vacuum degree in the vacuum chamber to be less than 10 - 3 Pa, pass argon or mixed gas into the vacuum chamber to a vacuum degree of 1 to 3 Pa, turn on the high-frequency high-voltage pulse power supply, adjust the output of the high-voltage pulse pow...

specific Embodiment approach 2

[0040] Embodiment 2: This embodiment differs from Embodiment 1 in that: in step 2, the voltage value of the output pulse of the high-frequency high-voltage pulse power supply is 1-6 kV, the pulse frequency is 400-1000 Hz, and the pulse width is 15-20 μs. Others are the same as the first embodiment.

specific Embodiment approach 3

[0041] Specific embodiment three: the difference between this embodiment and specific embodiment one or two is: the process parameters of Si transition layer preparation in step three: pulse voltage value is 1~6kV, pulse frequency is 400~1000Hz, pulse width is 15~ 20μs. Others are the same as those in Embodiment 1 or 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com