Transition metal-doped molybdenum disulfide thin-layer material as well as preparation method and application thereof

A transition metal, thin-layer material technology, applied in the direction of metal material coating process, coating, gaseous chemical plating, etc., can solve the problems of large thickness of composite coating and small distribution size of products, and achieve controllable process and application The effect of range expansion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

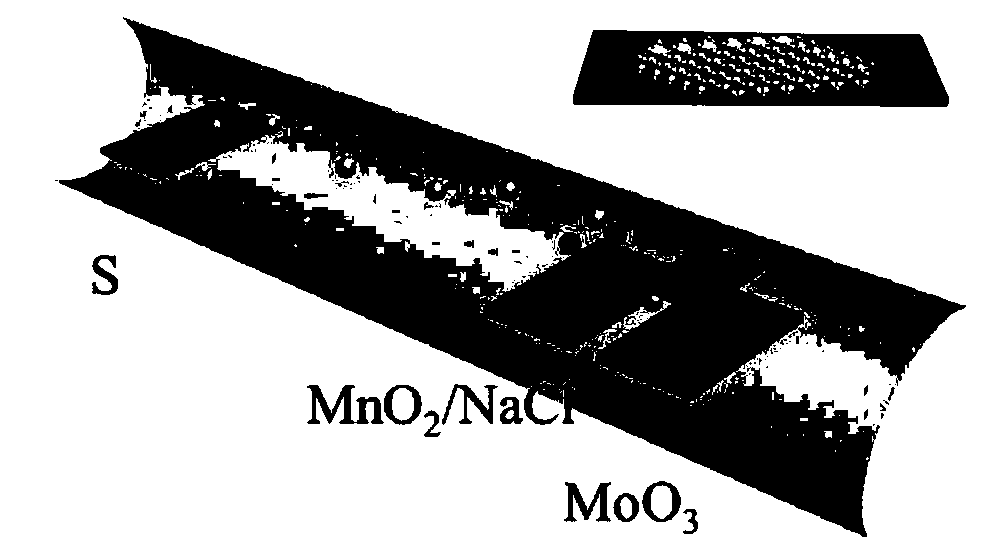

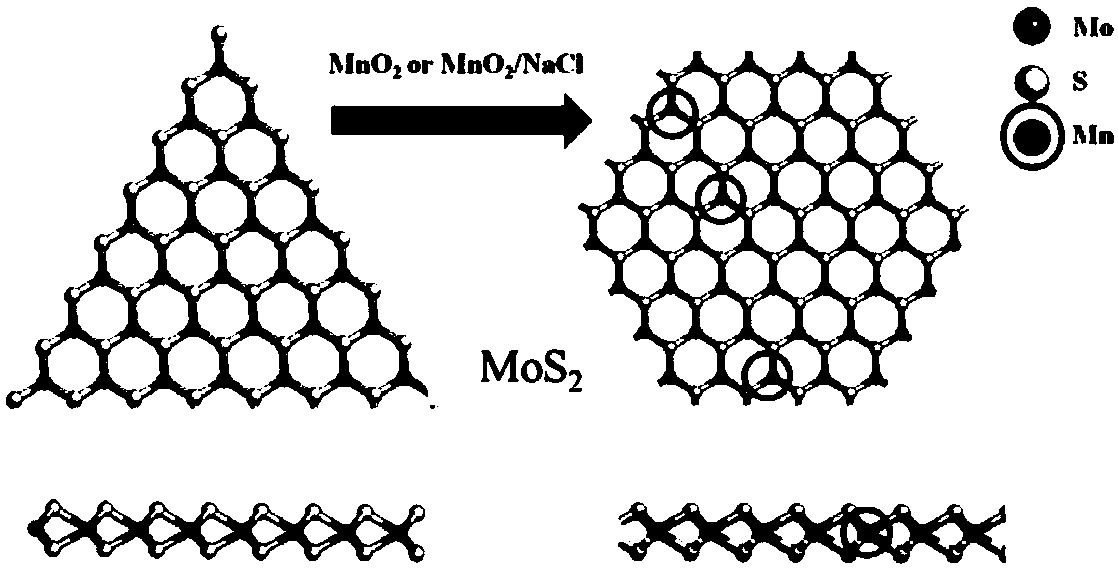

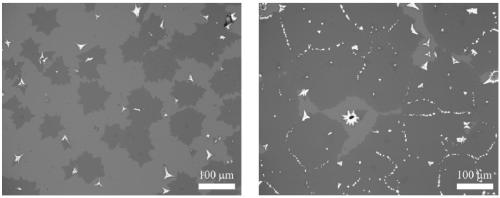

[0069] This embodiment provides a method for preparing a manganese-doped molybdenum disulfide thin layer material, and the schematic diagram of the method is as follows figure 1 As shown, the schematic diagram is as figure 2 shown, including the following steps:

[0070] (1) 10mg molybdenum trioxide and 20mg manganese dioxide are mixed with sodium chloride respectively, the mass ratio of molybdenum trioxide and sodium chloride is 6:1, and the mass ratio of manganese dioxide and sodium chloride is 2:1;

[0071] (2) molybdenum trioxide, manganese dioxide and Si / SiO mixed with sodium chloride in step (1) 2 The substrate is placed in the second heating zone of the tube furnace, the manganese dioxide is located at a distance of 6 cm from the upstream of the molybdenum trioxide, and the Si / SiO 2 The substrate is placed face down directly above the molybdenum trioxide, the sulfur powder is placed in the first heating zone upstream of the manganese dioxide, and the mass of the sulf...

Embodiment 2

[0076] This embodiment provides a method for preparing an iron-doped molybdenum disulfide thin layer material, the method comprising the following steps:

[0077] (1) 20mg molybdenum trioxide and 80mg ferric oxide are mixed with sodium chloride respectively, the mass ratio of molybdenum trioxide and sodium chloride is 3:1, and the mass ratio of ferric oxide and sodium chloride is 6: 1;

[0078] (2) molybdenum trioxide, ferric oxide and mica substrate mixed with sodium chloride in step (1) are placed in the second heating zone of the tube furnace, and ferric oxide is positioned at the upstream of molybdenum trioxide In the area of 3cm, the mica substrate is placed directly above the molybdenum trioxide, and the ammonium sulfide is placed in the first heating zone upstream of the ferric oxide, and the quality of the ammonium sulfide used is 600mg;

[0079] (3) In the tube furnace described in step (2), feed argon at a rate of 50 mL / min, the first heating zone maintains a heat...

Embodiment 3

[0083] This embodiment provides a method for preparing a cobalt-doped molybdenum disulfide thin layer material, the method comprising the following steps:

[0084] (1) 5mg molybdenum trioxide and 30mg cobalt oxide are mixed with potassium chloride respectively, the mass ratio of molybdenum trioxide and potassium chloride is 4.5:1, and the mass ratio of cobalt oxide and potassium chloride is 10:1;

[0085] (2) molybdenum trioxide, cobalt oxide and sapphire substrate mixed with potassium chloride in step (1) are placed in the second heating zone of tube furnace, cobalt oxide is positioned at the upstream of molybdenum trioxide and is apart from the region of 10cm, The sapphire substrate is placed face down directly above the molybdenum trioxide, diethyl sulfide is placed in the first heating zone upstream of the cobalt oxide, and the quality of diethyl sulfide used is 500 mg;

[0086] (3) In the tube furnace described in step (2), feed argon at a rate of 50 mL / min, the first hea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com