Ecological anticorrosive wood floor

A wood floor, ecological technology, applied in the field of ecological anti-corrosion wood floor, can solve the problems of perishable, polluted environment, etc., and achieve the effect of good moisture resistance, prevention of damp and mildew growth, and tight connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

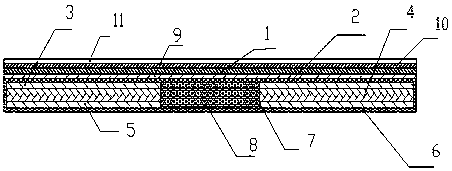

[0048] A kind of ecological anticorrosion wooden floor, comprises surface decoration veneer layer 1, the first moisture-proof layer 2, the first anticorrosion layer 3, plank layer 4, the second anticorrosion layer 5 and the second moisture-proof layer 6, described first moisture-proof layer 2 and The cross-section of the second moisture-proof layer 6 is a door shape, and the surface decoration veneer layer 1 is bonded on the upper surface of the first moisture-proof layer 2, and negative ion powder, 9, is arranged between the surface decoration veneer layer 1 and the first moisture-proof layer 2. An anti-corrosion layer 3 is bonded on the lower surface of the first moisture-proof layer 2, the wood layer 4 is bonded on the lower surface of the first anti-corrosion layer 3, the second anti-corrosion layer 5 is bonded on the lower surface of the wood layer 4, and the second The moisture-proof layer 6 is glued on the lower surface of the second anti-corrosion layer 5, and the two s...

Embodiment 2

[0080] This embodiment is basically the same as Embodiment 1, the difference is:

[0081] The negative ion powder layer is made of the following raw materials:

[0082] Nano titanium dioxide 22 parts

[0083] 20 parts diatomaceous earth

[0084] Titanium dioxide 8 parts

[0085] Nano tourmaline 24 parts

[0086] 12 parts of light calcium carbonate powder

[0087] 8 parts of talcum powder.

[0088] The first anti-corrosion layer and the second anti-corrosion layer are made by immersing wooden boards in a wood preservative solution, and the wood preservative solution includes the following raw materials in parts by weight:

[0089] 32 parts of propylene glycol

[0090] Potassium bromide 12 parts

[0091] 5.5 parts of p-chloro-m-xylenol

[0092] 2.5 parts of nano copper oxide particles

[0093] 12 parts copper naphthenate

[0094] Sodium benzoate 1.2 parts

[0095] Sodium pyrithione 3.2 parts

[0096] 142 parts of deionized water;

[0097] The anti-corrosion liquid a...

Embodiment 3

[0107] This embodiment is basically the same as Embodiment 1, the difference is:

[0108] The negative ion powder layer is made of the following raw materials:

[0109] Nano titanium dioxide 20 parts

[0110] 18 parts diatomaceous earth

[0111] 7 parts of titanium dioxide

[0112] Nano tourmaline 20 parts

[0113] 10 parts of light calcium carbonate powder

[0114] 6 parts of talcum powder.

[0115] The first anti-corrosion layer and the second anti-corrosion layer are made by immersing wooden boards in a wood preservative solution, and the wood preservative solution includes the following raw materials in parts by weight:

[0116] 28 parts of propylene glycol

[0117] Potassium bromide 10 parts

[0118] 4 parts p-chloro-m-xylenol

[0119] 1.5 parts of nano copper oxide particles

[0120] Copper naphthenate 10 parts

[0121] 1 part sodium benzoate

[0122] Sodium pyrithione 2 parts

[0123] 128 parts of deionized water;

[0124] The anti-corrosion liquid also inc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com