Method for preparing nano-black phosphorus by electric field and microwave field co-assisted stripping of black phosphorus

A technology of microwave field and black phosphorus, applied in the direction of phosphorus preparation, nanotechnology, nanotechnology, etc., can solve the problems of slow liquid intercalation, long time required, complicated equipment and process, etc., and achieve simple operation and short time consumption , large size effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

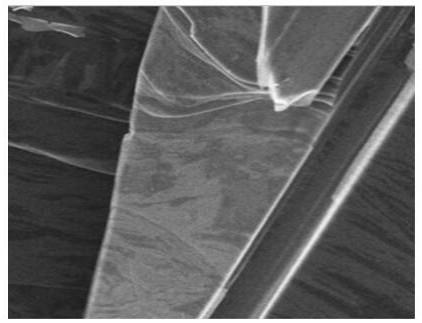

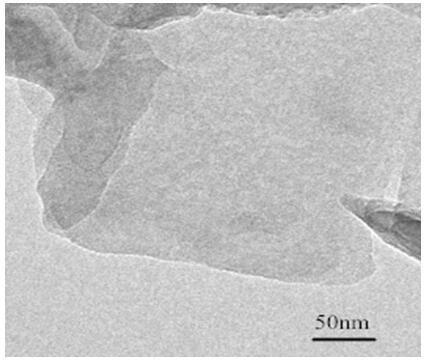

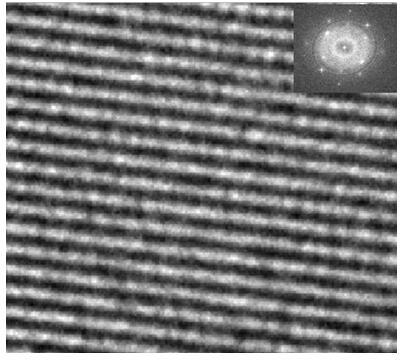

Image

Examples

Embodiment 1

[0025] Embodiment 1: A kind of method that electric field and microwave field synergistically assist exfoliate black phosphorus to prepare nanometer black phosphorus, concrete steps are:

[0026] (1) Fix the black phosphorus crystal on the metal rod with conductive glue as the working electrode, and the working electrode is the anode; use the platinum sheet as the counter electrode, place the working electrode and the counter electrode in parallel and vertically in the sulfuric acid electrolysis with a concentration of 1mol / L In the solution, the distance between the working electrode and the counter electrode is 2cm, and under the condition of voltage 3V, perform ion intercalation and exfoliate the black phosphorus sheet for 2h to obtain the intercalated black phosphorus dispersion A;

[0027] (2) Under a microwave power of 800W and an inert gas (argon) atmosphere, the intercalated black phosphorus dispersion A obtained in step (1) was subjected to microwave peeling treatment ...

Embodiment 2

[0031] Embodiment 2: A kind of electric field and microwave field assist the method for stripping black phosphorus to prepare nano black phosphorus, concrete steps are:

[0032] (1) Fix the black phosphorus crystal on the metal rod with conductive glue as the working electrode, and the working electrode is the anode; the platinum sheet is used as the counter electrode, and the working electrode and the counter electrode are placed in parallel and vertically on a dodecane with a concentration of 1mol / L. In the alkyl sodium sulfate electrolyte, the distance between the working electrode and the counter electrode is 3 cm, and under the condition of voltage 20V, perform ion intercalation and exfoliate the black phosphorus sheet for 0.5h to obtain the intercalated black phosphorus dispersion A;

[0033] (2) Under a microwave power of 300W and an inert gas (argon) atmosphere, the intercalated black phosphorus dispersion A obtained in step (1) was subjected to microwave peeling treatm...

Embodiment 3

[0035] Embodiment 3: A kind of method that electric field and microwave field synergistically assist exfoliate black phosphorus to prepare nanometer black phosphorus, concrete steps are:

[0036] (1) Fix the black phosphorus crystal on the metal rod with conductive glue as the working electrode, and the working electrode is the anode; use the platinum sheet as the counter electrode, place the working electrode and the counter electrode in parallel and vertically in the hydrogen phosphate with a concentration of 2mol / L In the diammonium electrolyte, the distance between the working electrode and the counter electrode is 5cm, and under the condition of a voltage of 10V, the ion intercalation and exfoliation of the black phosphorus sheet are carried out for 2 hours to obtain the intercalation black phosphorus dispersion A;

[0037] (2) Under a microwave power of 300W and an inert gas (argon) atmosphere, the intercalated black phosphorus dispersion A obtained in step (1) was subjec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com