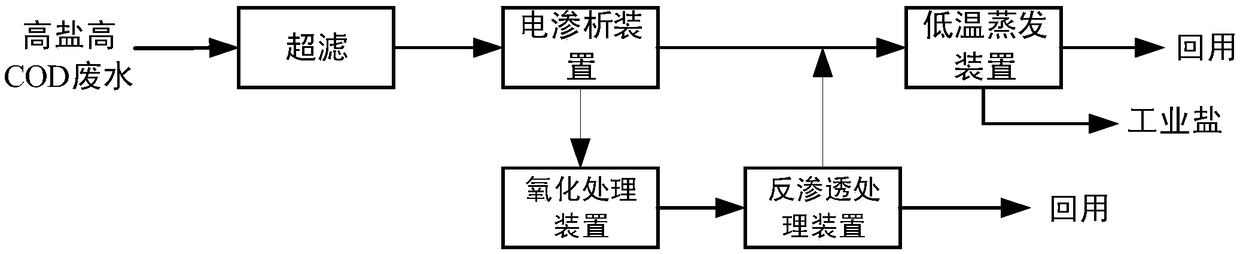

High-salt high-COD wastewater treatment zero emission process and device

A wastewater treatment and treatment device technology, applied in water/sewage treatment, multi-stage water/sewage treatment, heating water/sewage treatment, etc., can solve the problems of thick wastewater, affecting the life of the evaporator, and unable to further evaporate, etc., to achieve Effects of reducing evaporation energy consumption, solving reverse osmosis membrane fouling, and solving high osmotic pressure problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] The water quality of high-salt and high-COD wastewater in an enterprise is as follows: the salt concentration is 5%, the COD is 3230 mg / L, the pH is 6.3, and the temperature is 27°C. Firstly, the waste water is passed through the tubular Al with an average pore size of 5nm 2 o 3 Ceramic membrane treatment removes suspended solids in wastewater, the operating pressure is 0.4 MPa, and the membrane surface velocity is controlled at 2m / s. The wastewater treated by the ultrafiltration membrane enters the electrodialysis treatment device, the operating voltage is 80 V, and the current is 2A. The COD of the desalted fresh water after electrodialysis treatment is 3020 mg / L, and the salt concentration is 0.5%. , The reverse osmosis membrane material is polyimide, the operating pressure is 1.2MPa, after the wastewater is concentrated 5 times, the concentrated water enters the low-temperature evaporation device for treatment, and the effluent is reused. The COD of the high-conc...

Embodiment 2

[0058] The water quality of high-salt and high-COD wastewater in a papermaking enterprise is: the salt concentration is 15%, the COD is 47850 mg / L, the pH is 6.9, and the temperature is 20°C. Firstly, the wastewater is treated with a plate-type PVDF ultrafiltration membrane with an average pore size of 20nm to remove suspended solids in the wastewater. The operating pressure is 0.3 MPa, and the membrane surface velocity is controlled at 3 m / s. The wastewater treated by the ultrafiltration membrane enters the electrodialysis treatment device with an operating voltage of 120 V and a current of 3 A. The COD of the desalted fresh water after electrodialysis treatment is 47201 mg / L, and the salt concentration is 1.2%. Osmosis treatment device, the reverse osmosis membrane material is cellulose acetate, the operating pressure is 1.5 MPa, after the wastewater is concentrated by 3 times, the concentrated water enters the low-temperature evaporation device for treatment, and the efflue...

Embodiment 3

[0060] The water quality of high-salt and high-COD wastewater in a printing and dyeing enterprise is: the salt concentration is 23%, the COD is 32500 mg / L, the pH is 7.8, and the temperature is 25°C. Firstly, the waste water is passed through the tubular Al with an average pore size of 50nm 2 o 3 Ultrafiltration ceramic membrane treatment removes suspended solids in wastewater, the operating pressure is 0.2 MPa, and the membrane surface velocity is controlled at 5 m / s. The wastewater treated by the ultrafiltration membrane enters the electrodialysis treatment device with an operating voltage of 190 V and a current of 4 A. The COD of the desalted fresh water after electrodialysis treatment is 31200 mg / L, and the salt concentration is 3%. Osmosis treatment device, the reverse osmosis membrane material is polyimide, the operating pressure is 1.8MPa, after the wastewater is concentrated twice, the concentrated water enters the low-temperature evaporation device for treatment, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com