Wall surface spraying raw material and spraying method

A raw material and water reducing agent technology, applied in the direction of construction, building structure, etc., can solve the problems of water resistance, thermal insulation and anti-crack defects, and achieve the effect of shortening the mixing time, good fusion, and enhancing the anti-crack performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] A raw material for wall surface spraying, comprising the following components in parts by mass: 180g of gypsum powder, 104g of water, 20g of soft clay, 20g of silicone resin, 6g of vitrified microbeads, 5g of water reducing agent, 3g of crosslinking agent, Expanded graphite 2g. The silicone resin is any one of methyltrichlorosilane, dimethyldichlorosilane or phenyltrichlorosilane. The water reducer is any one of fatty acid-based water-reducer, naphthalene-based water-reducer or sulfamic acid-based water-reducer. The crosslinking agent is any one of dicumyl peroxide, benzoyl peroxide or di-tert-butyl peroxide.

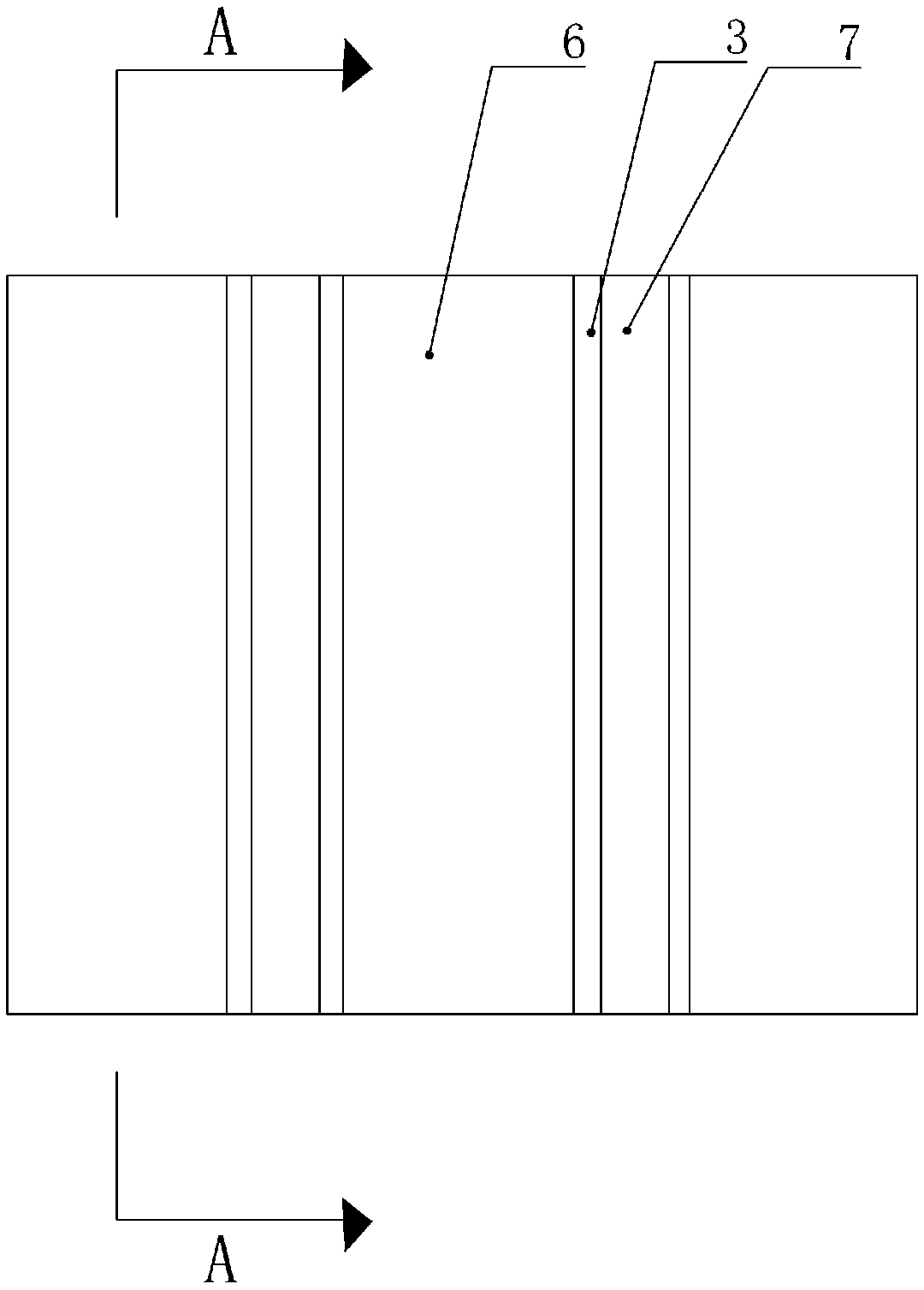

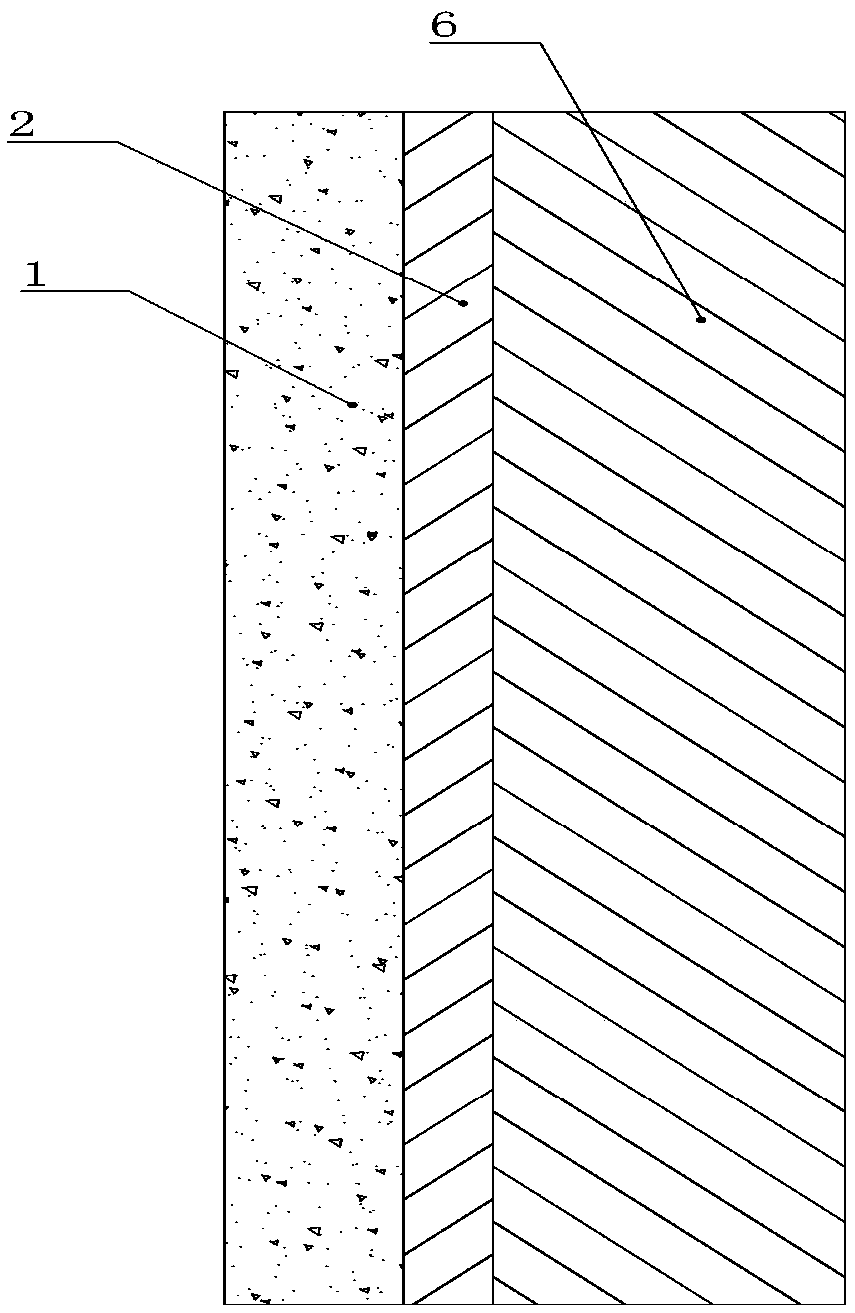

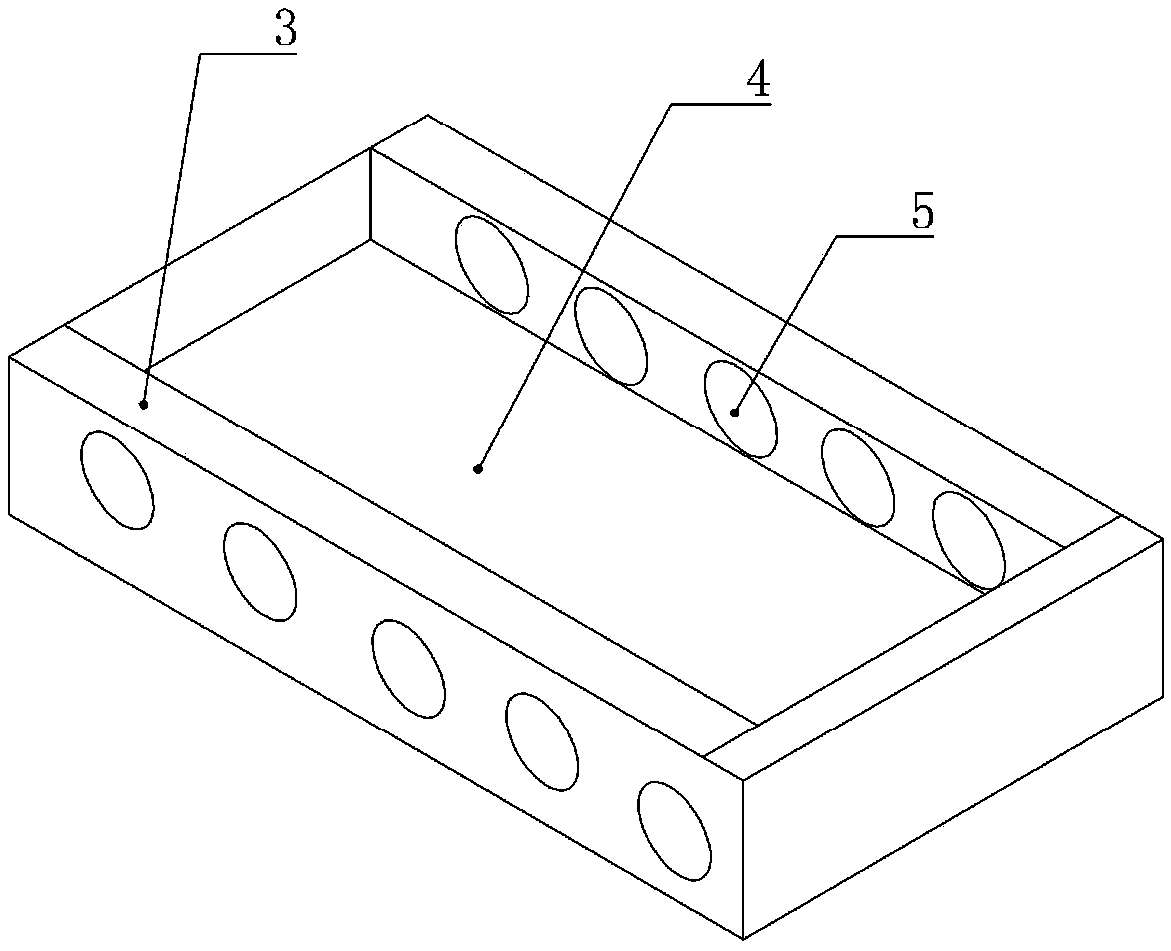

[0031] Such as figure 1 , figure 2 and image 3 As shown, the wall surface includes a wall base layer 1, a first layer of wall surface 2 and a second layer of wall surface 6 from the inside to the outside, the first layer of wall surface 2 includes a new glass fiber cloth containing airgel, and the new The glass fiber cloth is bonded to the base layer 1 of ...

Embodiment 2

[0047] Example 2 Compared with Comparative Example 1, no soft clay was added in Comparative Example 1, and the waterproofness of the wall surface was relatively weak. Among them, the vitrified microbeads played a certain waterproof effect, but the effect was relatively limited, causing moisture to enter the wall surface Inside, so that the wall material has partially fallen off.

[0048] Embodiment 2 Compared with comparative example 2, the wall surface sprayed by comparative example 2 is wet and has poor thermal insulation. Vitrified microbeads are not added in comparative example 2, which causes the water resistance of the sprayed raw material to be greatly reduced. Simultaneously, although there is expansion in the sprayed raw material Graphite, but with limited insulating properties.

[0049] Compared with Example 2 and Comparative Example 3, the wall surface sprayed in Comparative Example 3 has obvious cracks. In comparative example 3, there are separate vitrified microb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com