High-permeability coloring environment-friendly ceramic product and making method thereof

A ceramic product, high-penetration technology, applied in the field of ceramics, can solve the problems of difficulty in coloring ceramic products, the pattern is easy to wear off, and there are not too many successful technologies, and achieve the effects of high strength, lower sintering temperature, and lower sintering temperature.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] A highly permeable colored environmentally friendly ceramic product, comprising a body and a permeable layer applied on the surface of the body, the body includes the following raw materials in parts by weight:

[0031] 38 parts by weight of kaolin;

[0032] Aluminum oxide 24 parts by weight;

[0033] 10 parts by weight of wollastonite;

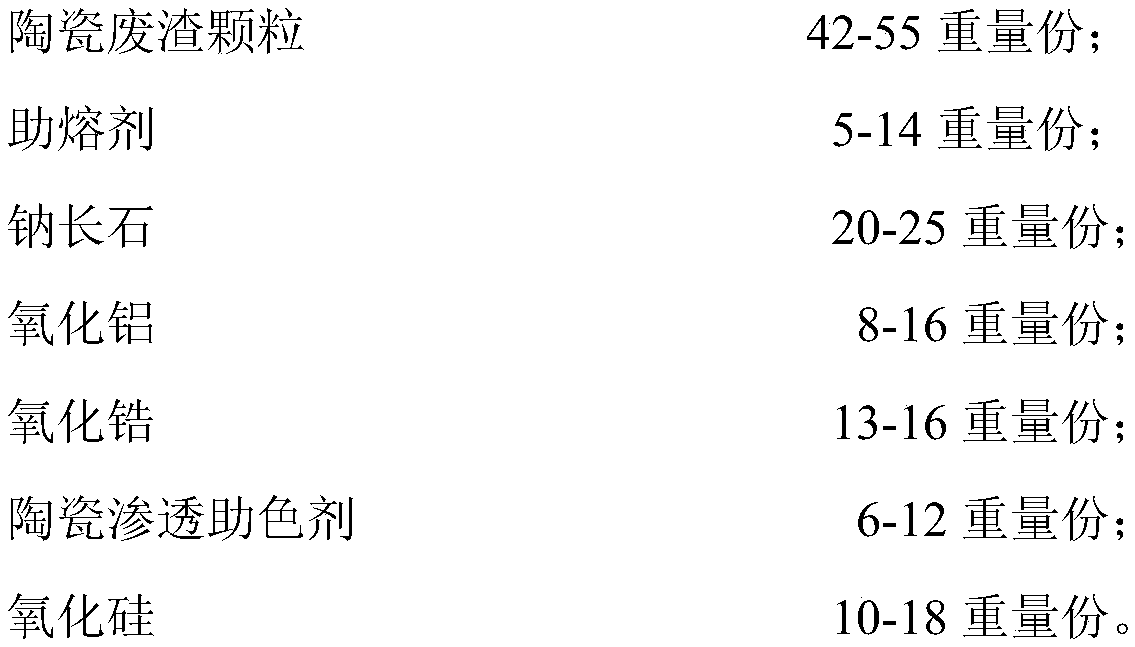

[0034] The permeable layer includes the following raw materials in parts by weight:

[0035]

[0036]

[0037] Specifically, the flux is composed of sodium oxide, potassium carbonate and sodium silicate in a mass ratio of 1:2:2.

[0038] Specifically, the particle size of the ceramic waste slag is 12mm.

[0039] Specifically, the ceramic penetrating color aid is fumed white carbon black.

[0040] Specifically, the thickness of the permeable layer is 2.3mm.

[0041] The technique of making described a kind of highly permeable colored environment-friendly ceramic product comprises the following steps:

[0042] S1 Raw material...

Embodiment 2

[0047] A highly permeable colored environmentally friendly ceramic product, comprising a body and a permeable layer applied on the surface of the body, the body includes the following raw materials in parts by weight:

[0048] 28 parts by weight of kaolin;

[0049] Aluminum oxide 19 parts by weight;

[0050] Wollastonite 8 parts by weight;

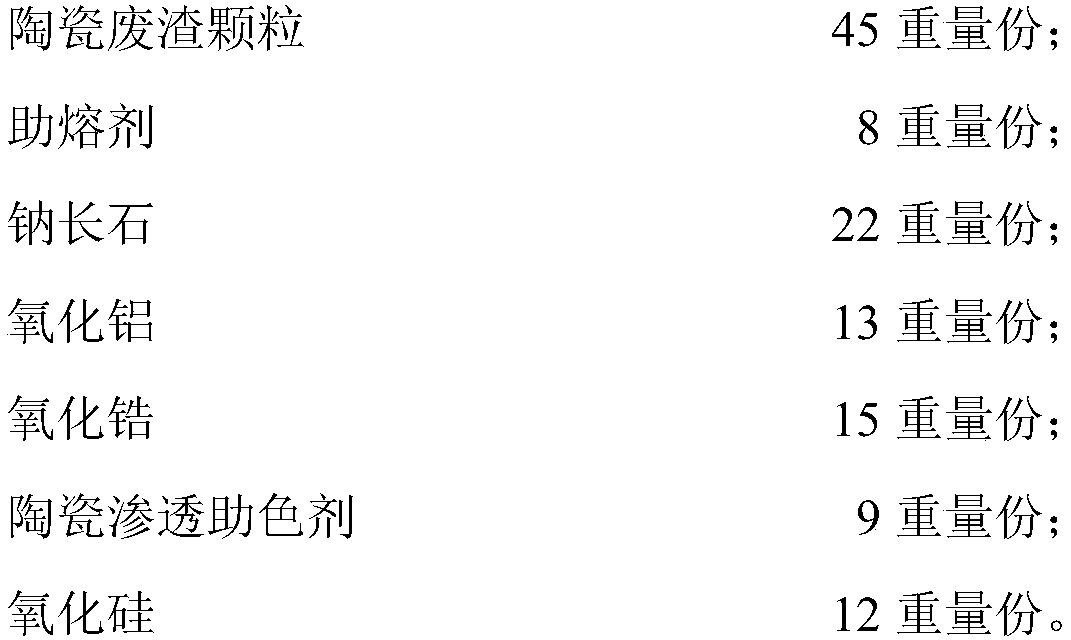

[0051] The permeable layer includes the following raw materials in parts by weight:

[0052]

[0053]

[0054] Specifically, the flux is composed of sodium oxide, potassium carbonate and sodium silicate in a mass ratio of 1:2:2.

[0055] Specifically, the particle size of the ceramic waste slag is 9mm.

[0056] Specifically, the ceramic penetrating color aid is fumed white carbon black.

[0057] Specifically, the thickness of the permeable layer is 1.8mm.

[0058] The technique of making described a kind of highly permeable colored environment-friendly ceramic product comprises the following steps:

[0059] S1 Raw material prep...

Embodiment 3

[0064] A highly permeable colored environmentally friendly ceramic product, comprising a body and a permeable layer applied on the surface of the body, the body includes the following raw materials in parts by weight:

[0065] 38 parts by weight of kaolin;

[0066] Aluminum oxide 24 parts by weight;

[0067] 10 parts by weight of wollastonite;

[0068] The permeable layer includes the following raw materials in parts by weight:

[0069]

[0070] Specifically, the flux is composed of sodium oxide, potassium carbonate and sodium silicate in a mass ratio of 1:2:2.

[0071] Specifically, the particle size of the ceramic waste slag is 12mm.

[0072] Specifically, the ceramic penetrating color aid is fumed white carbon black.

[0073] Specifically, the thickness of the permeable layer is 2.3mm.

[0074] The technique of making described a kind of highly permeable colored environment-friendly ceramic product comprises the following steps:

[0075] S1 Raw material preparation...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com